With the explosion of 3D printing reaching users ranging from worldwide manufacturing organizations to families looking for an innovative way to encourage creativity, it’s no surprise that more and more of the population are eager to incorporate it into their professional and personal lives. This technology, that at one time was only available at a high cost thought impractical to leading businesses and manufacturers across many industries, is fast becoming a mainstay in countless applications. As companies and startups alike shift focus to accelerating product development, 3D printing has provided drastic improvements to prototyping, production, and proof of concept models throughout varied industries. Before we get into the details of its operation, let’s take a look backto see how long ago this tech became available.

History

While 3D printing is has been thought to be a cutting edge futuristic technology, its fundamental concept has been available for over 30 years. In 1983, Chuck Hull, executive vice president and co-founder of 3D Systems, was the first to invent and introduce the term stereolithography (SL or SLA). He defined this as the process used to develop a solid object made by printing fine tiers of ultraviolet curable material in layers. Hull was granted a US patent for his innovative design in 1986 which added additional detail to the science stating:

“A programmed movable spot beam of UV light shining on a surface or layer of UV curable liquid is used to form a solid cross-section of the object at the surface of the liquid. The object is then moved, in a programmed manner, away from the liquid surface by the thickness of one layer, and the next cross-section is then formed and adhered to the immediately preceding layer defining the object. This process is continued until the entire object is formed.” (US Patent 4575330)

As computing and imaging technology advanced throughout the years, 3D printing has evolved to include the use of 3D modeling software and/or the inclusion of 3D scanners as starting points of object design prior to the development of a prototype of a product. The applicable materials available to this process have grown beyond polymers to now include clays, metals and alloys, ceramics, and even carbon fiber thus making the concepts for 3D printing almost endless. This is made possible by the progressions made in printing types which have grown beyond stereolithography to include fused deposition modeling (FDM), electron-beam melting (EBM), selective laser sintering (SLS), laminated object manufacturing (LOM), and electron beam freeform fabrication (EBF³).

What is needed for 3D printing?

The first step in creating a 3D printed object begins with conceptualization of a digital twin image either by an original model using modeling software or a 3D scan of an existing article rendered via 3D scanning device(s). Scanners using white light or blue light spectrums, when combined with advanced digital camera technology, provide an object with X, Y, and Z coordinates on a plane. Once a computer aided design/manufacturing (CAD/CAM) file or scanned image is created, it can be analyzed and processed to construe data points of the object. This enables engineers to virtually interact with the item to quickly and efficiently address problems and take proactive a position to improve design before mass manufacturing takes place. Software will also ‘slice’ the object within the file into hundreds to thousands of layers in preparation for print.

Capture 3D, the exclusive North American partner for GOM Germany, which specializes in optical measuring devices, provides a multitude of 3D scanning device options to maximize opportunities and throughput for a myriad of industries. Our ATOS scanners product category provides optical scanners capable suited for varied industrial applications to measure reflective surfaces or complex components such as turbine blades and airfoils. For accurate and rapid coordinate measurements, our TRITOP systems are designed to operate as a standalone photogrammetry device supplementing inspection and deformation studies while also compatible with ATOS for sizeable areas. Capture 3D’s patented MC-XL provides automated multi-axis motion control 3D scanning capabilities ideal for laboratory and office settings with ruggedized design for industrial environments as well.

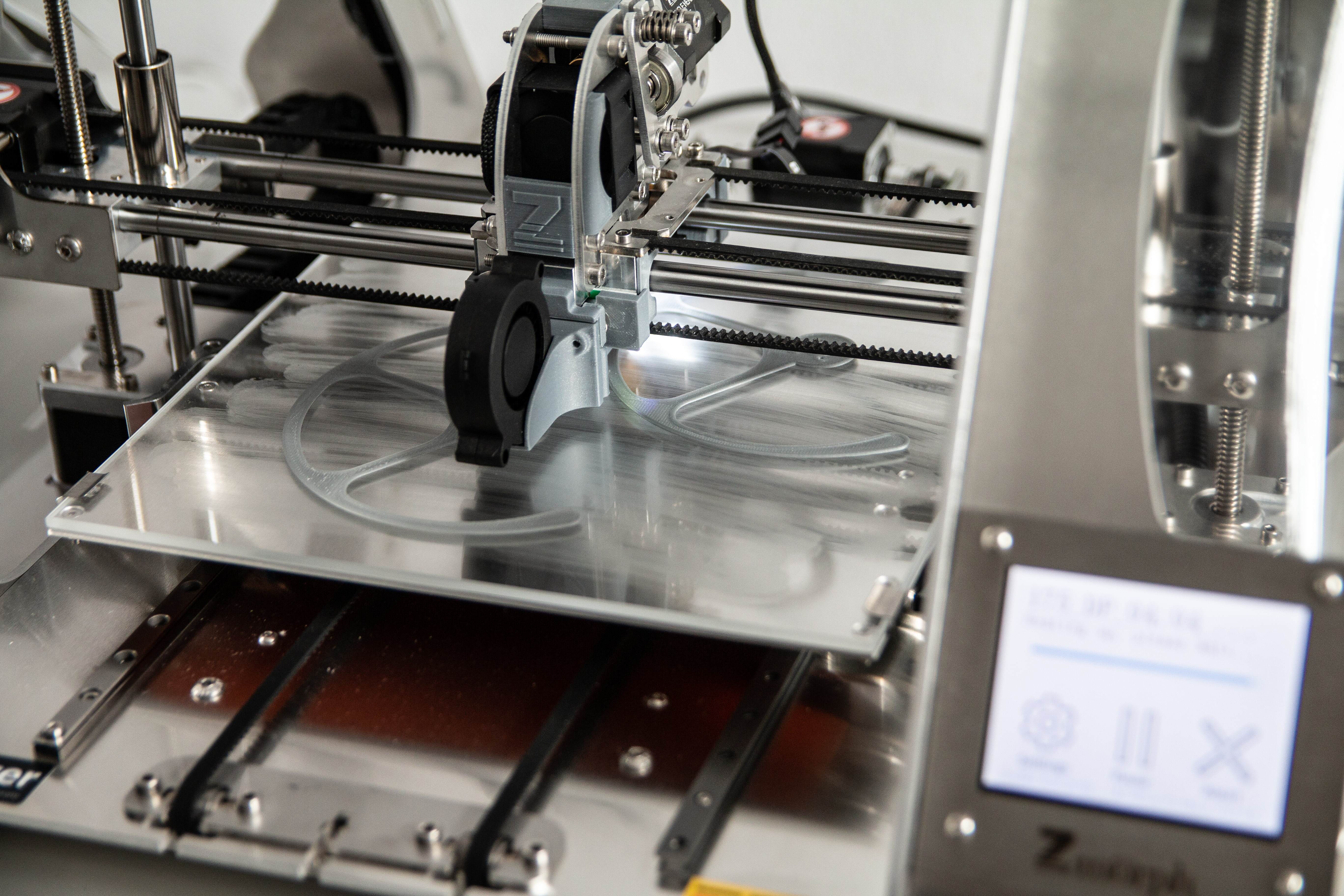

After the CAD/CAM file or object image is ready for print, it is loaded onto a selected printing device of which there is a wealth of options depending on the 3D printing method chosen for the business purpose. Fused Deposition Modeling is an extrusion based process that uses a printer head to extrude small streams or beads of a selected material over a platform. First it projects a layer of molten plastic within a print bed that adheres for stability. After the first layer is in place, the print bed lowers and the print head follows the coordinates from the CAD/CAM or image it was provided to complete the 3D print. FDM is has become the most popular form of 3D printing in 2018 rising to 46% of a 3D print users compared to 36% in 2017 (Statista). This is most likely due to the wide range of materials available for use such as polymers, metals, and glass providing variability and creativity its users. It is also a very cost effective method as the filaments used by the printer are available at a lower cost when compared to some SLA practices where the fluid required has higher price tag.

Selective Laser Sintering is another popular 3D print method as well, but has a higher cost applied to its process. In SLS, a laser is used to melt then solidify layer after layer of powder material in order to complete a print. These types of printers utilize two different print beds that are known as pistons. When the printer is ready to create an object, the laser first plots the initial layer of the item in a selected material powder by melting, or sintering, the material. After the layer becomes solid, the bed lowers and the 2nd bed rises to allow a roller to apply another level of powder on top of the first. The process repeats over and over as the laser continues to meld each layer together until the desired object is complete.

Benefits of 3D Printing

Today, the world has been set afire with the endless possibilities and opportunities 3D printing has allowed in what appears to be almost every industry. In healthcare, South Korean researchers have successfully developed bio-blood vessels from a template of human body material extractions. It was found that during efficacy testing of a control group that contained the blood vessel implants were seven times less likely to develop necrosis. Professors believe it is possible create desired blood vessels using this technology and can lead to creation of implants such as arteries (Korea Bizwire). 3D printed prosthetics in the Middle East are proving to have the same functionality as traditional devices, but are available at as little as half the cost (Tahawul Tech).

Binder jetting, another variance to 3D printing, can print in full color to help artists and engineers create sculptures and models. Electron Beam Melting is used for industrial metal printing of steel, aluminum, and even titanium that is widely applied to aerospace, automotive, and healthcare industries for mechanical components that are lighter, smaller, and at a lowered cost.

As we can all deduce by now, 3D printing is not only here to stay, but continues to expand our horizons with what seems to be innumerable opportunities in almost as many applications that we have only begun to discover.

Who Can I Contact To Learn More?

Capture3D is devoted to the continued success of each of our customers through our knowledgeable specialized team members that are well versed today’s business and consumer needs. Our offering of top quality advanced products are designed and engineered to provide complete 3D metrology solutions with precision accuracy coupled with lightning speed for seamless operation. Please contact us today to allow us to begin development of a customized solution that addresses the vital demands of your focused needs.