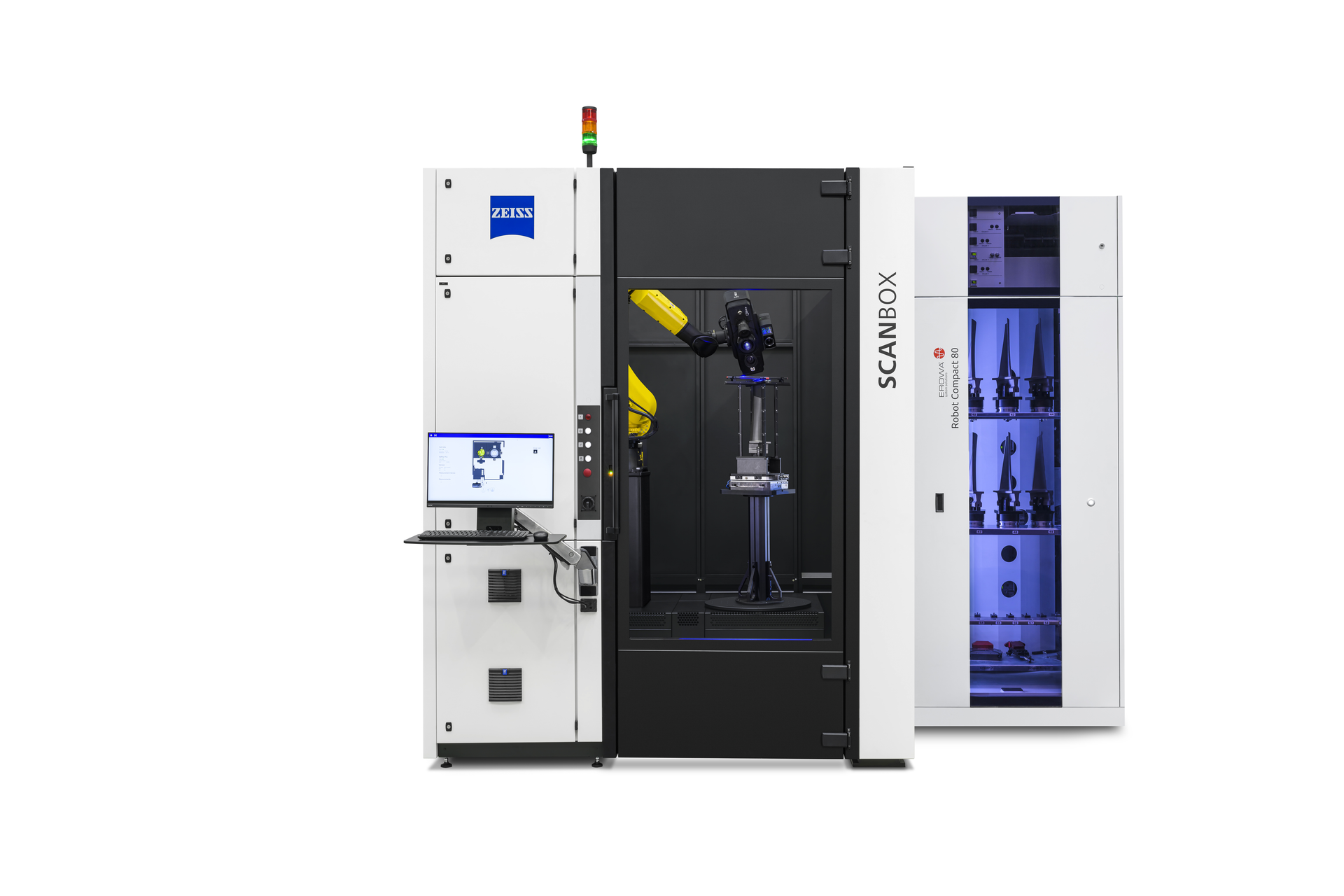

ATOS ScanBox BPS

A batch processing system enables automated loading and unloading of the optical 3D coordinate measuring machine. For this reason, the ATOS ScanBox is extended by a handling system and a PLC Interface Station. The ATOS ScanBox BPS is the solution for full-field digitization of a batch of parts with a height of up to 500 mm.

Benefits

Automated time savings

As the user creates a digital twin and does not have to place the individual parts, the time required for quality assurance is significantly shorter than before. The ATOS ScanBox BPS measures automatically up to 11 hours with few operator interventions. Personnel costs are decreased and machine utilization is increased.

Increased process reliability

Because the parts are marked, for example, with an RFID chip, the system independently detects which measuring program must be executed and which inspections are to be performed. Eliminating the impact of the user on the measurement significantly increases the process reliability.

Production-integrated 3D measurement technology

Robustness, measuring speed and compensation for temperature fluctuations are convincing factors of the ATOS ScanBox BPS in production. Work-intensive transports of a whole batch of parts, electrodes or turbine components are no longer necessary.

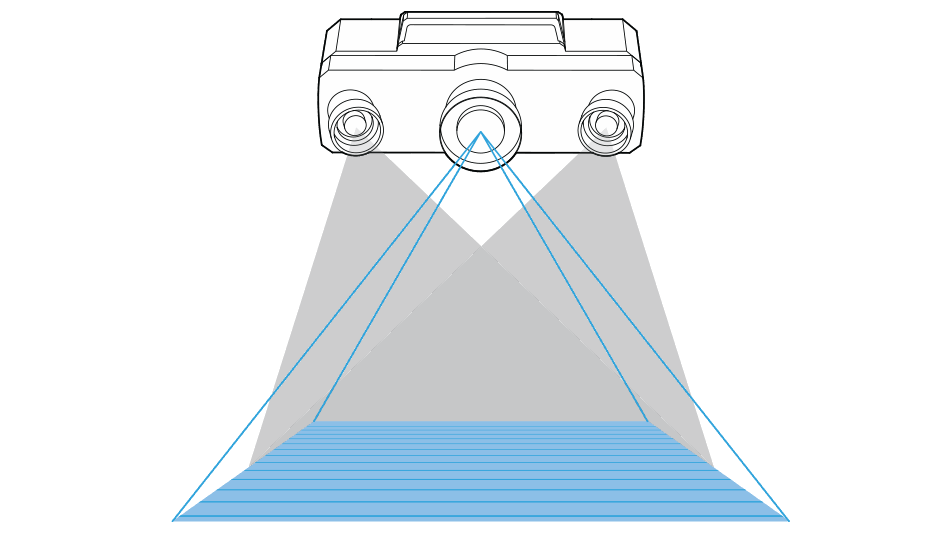

Sensor Technology

ATOS sensors provide full-field 3D coordinates for each individual measurement. Within a few seconds, up to 16 million independent measuring points are captured per scan. As a result, the measuring data is characterized by very high detailed reproduction, thereby enabling very small component features to be measured.

ATOS Overview >

Sensor Compatibility

ATOS sensors provide full-field 3D coordinates for each individual measurement. Within a few seconds, up to 12 million independent measuring points are captured per scan. As a result, the measuring data is characterized by very high detailed reproduction, thereby enabling very small component features to be measured.

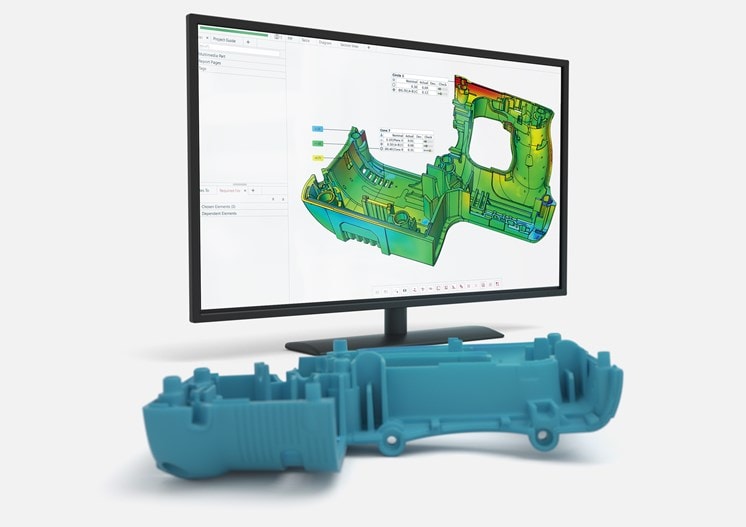

ZEISS INSPECT

3D Scanning and Inspection Software

ZEISS INSPECT Optical 3D is a process-reliable software solution that controls ATOS 3D scanners, produces precise 3D surface data and offers complete inspection and reporting functionalities in one software package.

ZEISS INSPECT Optical 3D is a complete parametric and traceable measuring and evaluation software for dimensional analyses. The intuitive operating concept makes it possible to implement all measuring tasks easily and flexibly.

ATOS ScanBox BPS

For further information about the ATOS ScanBox BPS, please download the brochure.

Download PDF

Available Standard Configurations

Solution 1 |

Solution 2 |

Solution 3 |

|

| Typical applications | Electrodes | Blades | Blades |

| Max. part diameter [mm] | 50 | 72 | 115 |

| Max. part height [mm] (incl. clamping/fixture) | 150 | 300 | 500 |

| Max. part weight [kg] | 20 | 20 | 40 |

| Max. batch size | 132 | 88 | 25 |

| Typical self-sufficient runtime [h] | 11 | 8 | 3 |