ATOS ScanBox Series 4

Injection-molded parts and die-cast components as well as tools, molds, stamping and bending parts often show complex contours and connection geometries which have to be checked during series and batch production ramp-up.

Technology

Space saving

All ATOS ScanBox models are characterized by their compact design. The ATOS ScanBox models 4105, 5108 and 5120 do not have to be anchored in the floor of the factory or on special measuring tables. They can easily be transported to the required place within a short period. All that is needed at the location is a power connection.

Plug & Play

The robust machine housing contains all components of the ATOS ScanBox. As a 100 – 240 V power supply is used and the measuring system only weighs approx. 900 kg, it can be used for measuring in almost all premises. Four wheels enable the unproblematic repositioning of the ATOS ScanBox in the factory shop. The sliding door is designed in such a way that the ATOS ScanBox can be loaded with a crane.

High detail image resolution

Small geometries, such as locking hooks or catches for injection-molded parts, are often very important for the function. The ATOS ScanBox 4105 can be used with ATOS sensors with the measuring area of 70 × 50 mm2. As a result, it is possible to measure details that are only several tenths of a millimeter in size.

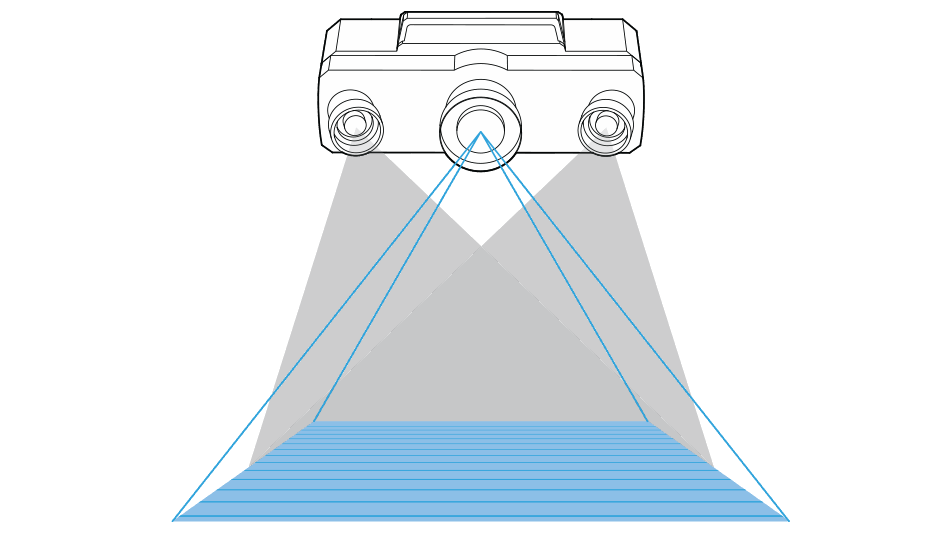

Sensor Technology

ATOS sensors provide full-field 3D coordinates for each individual measurement. Within a few seconds, up to 16 million independent measuring points are captured per scan. As a result, the measuring data is characterized by very high detailed digital twin reproduction, thereby enabling very small component features to be measured.

ATOS Overview >

Sensor Compatibility

ATOS sensors provide full-field 3D coordinates for each individual measurement. Within a few seconds, up to 12 million independent measuring points are captured per scan. As a result, the measuring data is characterized by very high detailed reproduction, thereby enabling very small component features to be measured.

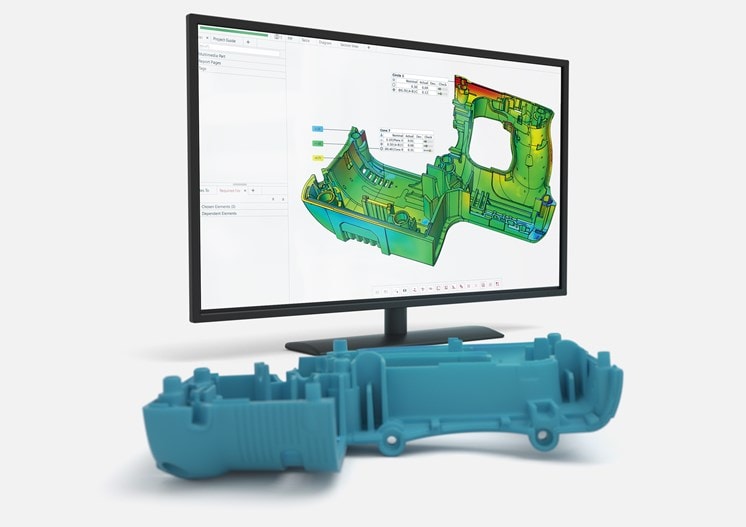

ZEISS INSPECT

3D Scanning and Inspection Software

ZEISS INSPECT is a process-reliable software solution that controls ATOS 3D scanners, produces precise 3D surface data and offers complete inspection and reporting functionalities in one software package.

ZEISS INSPECT is a complete parametric and traceable measuring and evaluation software for dimensional analyses. The intuitive operating concept makes it possible to implement all measuring tasks easily and flexibly.

ATOS ScanBox Brochure

For further information about the ATOS ScanBox, please contact us to request a copy of the brochure.

Download PDF

Technical Information

ATOS ScanBox 4105

| Dimensions | 1600 × 1200 × 2100 mm³ |

| Power supply | Standard, 100 – 240 V (1-phase, 16 A) |

| Max. part size | Ø 500 mm |

| Max. part weight | 100 kg |

| Entry | Sliding door with safety lock |

| Opening width | 685 mm |

| Floor mounting or fixing | Not required, mobile |

| Loading concept | Manual, crane |

| Sensor compatibility | ATOS Q |