ATOS ScanBox Series 7

Measurement of Large and Heavy Components up to 6000 mm in Size

Download Brochure

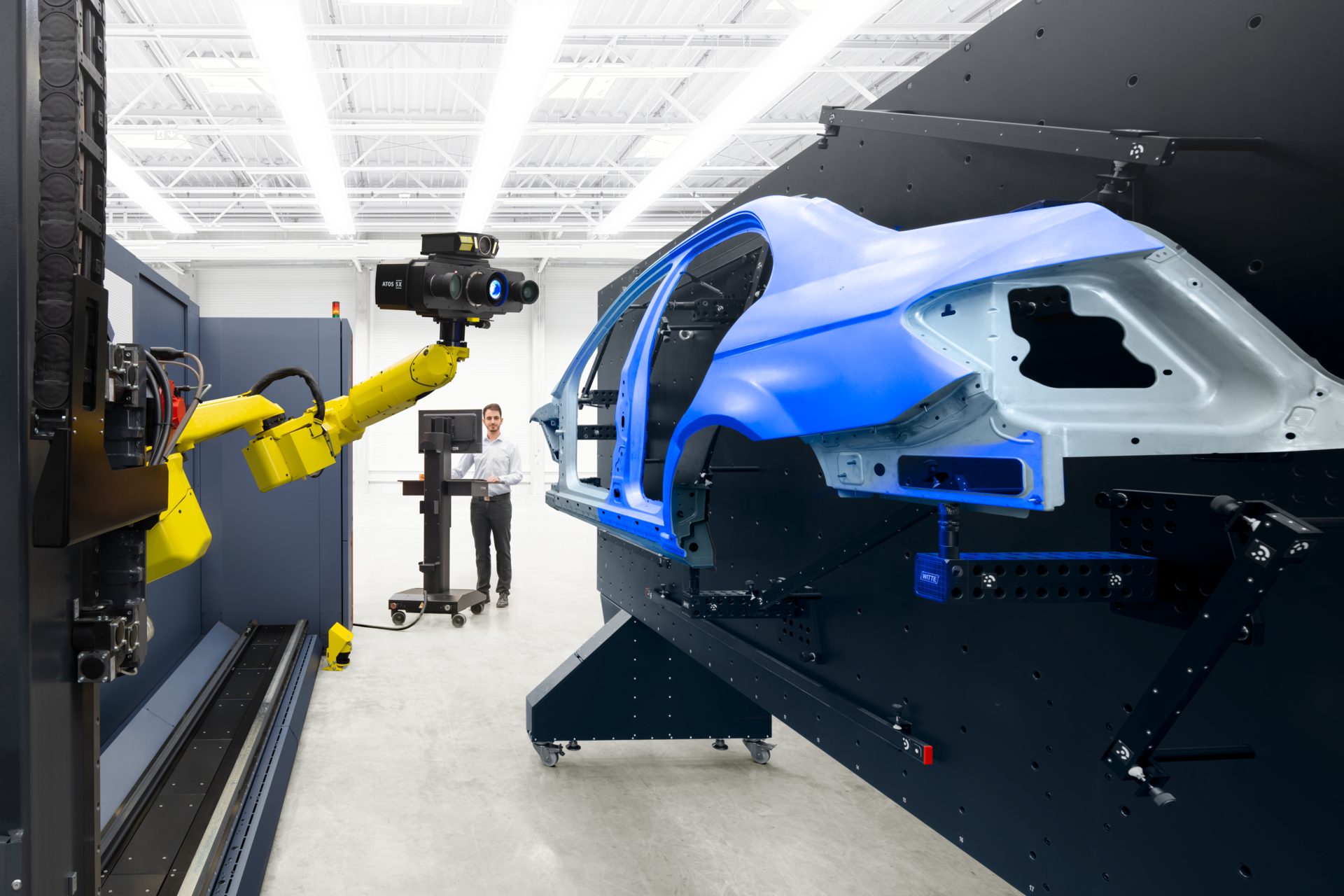

ATOS ScanBox Series 7

The ATOS ScanBox Series 7 is mainly used in car manufacturing, in try-out toolmaking and in press shops. The optical 3D measuring system performs complete analysis measurements for comparison in the introductory phase or is used for quality assurance in production.

Large parts such as automobile side panels and attached parts of up to 6 m in size can be measured. The full-field measuring data enables the analysis of hole patterns, trimming and character lines. Heavy and large parts for other applications can also be measured and inspected with the ATOS ScanBox Series 7.

Technology

8-axis kinematics

ScanBox Series 7 is an 8-axis kinematic system for measuring very large parts. Thanks to the 8 degrees of freedom, the combination of a linear axis, a vertical lift, an articulated robot, and an integrated cable duct allows high flexibility in positioning the sensor.

Modular layout

Uniform construction components and the modular structure of the ATOS ScanBox Series 7 and 8 enable a demand-oriented extension of the ATOS ScanBox both within Series 7 and to Series 8.

Rotation table working area

The ATOS ScanBox 7260 also has a rotation table working area. This corresponds to the ATOS ScanBox 6130 and enables additional measurements of medium-sized components. The rotation table can be loaded with a pallet system and thus guarantees quick, repeatable and exact component positioning.

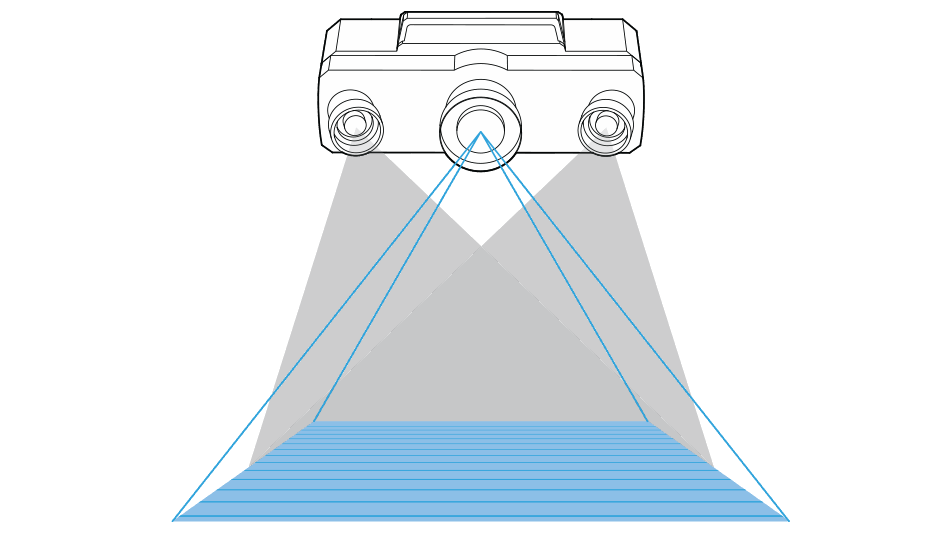

Sensor Technology

ATOS sensors provide full-field 3D coordinates for each individual measurement. Within a few seconds, up to 16 million independent measuring points are captured per scan. As a result, the measuring data is characterized by very high detail reproduction, thereby enabling the measurement of very small component features.

ATOS Overview >

Sensor Compatibility

ATOS sensors provide full-field 3D coordinates for each individual measurement. Within a few seconds, up to 12 million independent measuring points are captured per scan. As a result, the measuring data is characterized by very high detailed reproduction, thereby enabling very small component features to be measured.

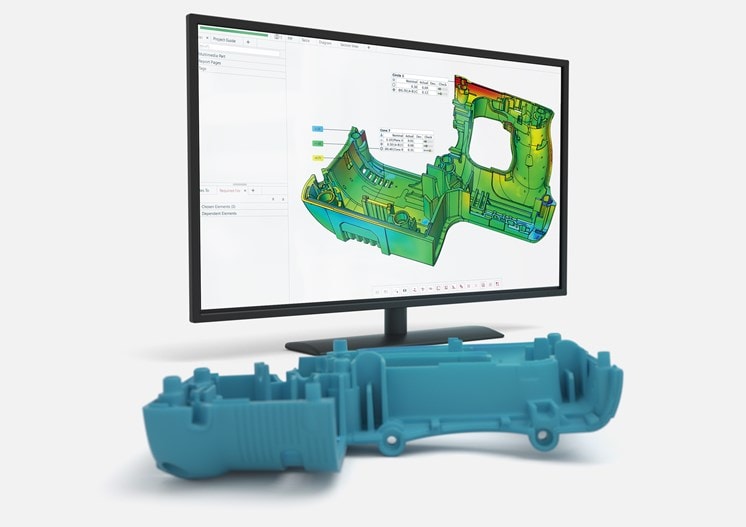

ZEISS INSPECT

3D Scanning and Inspection Software

ZEISS INSPECT is a process-reliable software solution that controls ATOS 3D scanners, produces precise 3D surface data and offers complete inspection and reporting functionalities in one software package.

ZEISS INSPECT Optical 3D is a complete parametric and traceable measuring and evaluation software for digital twin creation and dimensional analyses. The intuitive operating concept makes it possible to implement all measuring tasks easily and flexibly.

ATOS ScanBox Brochure

For further information about the ATOS ScanBox, please download the brochure.

Download PDFTechnical Information

ATOS ScanBox 7160 |

ATOS ScanBox 7260 |

|

| Dimensions | 4750 × 10150 × 3900 mm | 8750 × 10150 × 3900 mm |

| Power supply | 200–500 V (3-phase, 32 A) | 200–500 V (3-phase, 32 A) |

| Max. part size | 6000 × 1250 mm | 6000 × 1250 mm, rotation table working area up to Ø 3000 mm |

| Max. part weight | Unlimited | Unlimited, rotation table working area up to 2000 kg |

| Entry | Safety light curtain | Safety light curtains |

| Opening width | 3050 mm | 3050 mm, rotation table working area up to 3400 mm |

| Floor mounting or fixing | Required | Required |

| Loading concept | Manual, transport cart, pallet truck, crane, forklift truck, sandwich panel transport system | Manual, transport cart, pallet truck, crane, forklift truck, sandwich panel transport system |

| Sensor compatibility | ATOS 5, ATOS 5X | ATOS 5, ATOS 5X |