ZEISS Technology Day

Solutions for eMobility and Car Body Construction

Wednesday, July 21, 2021

Morning Session: eMobility Solutions 8:00 to 11:30 a.m. ET

Lunch: 11:30 a.m. to 12:30 p.m. ET

Afternoon Session: Car Body Solutions 12:30 to 4:00 p.m. ET

ZEISS Quality Excellence Center

29295 Lyon Oaks Drive

Wixom, MI 48393

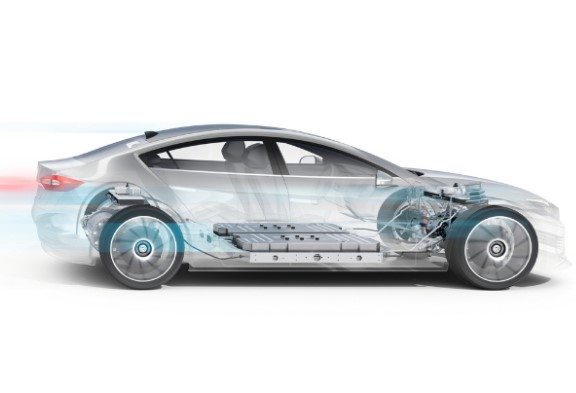

We're excited to begin safely welcoming you back to in-person events! Visit the CAPTURE 3D team at the ZEISS Quality Excellence Center this July for a complimentary event. In the afternoon session, we will share our insights into how leading EV manufacturers use Digital Assembly to support efficiency and innovation.

Manage the rapid changes in the automotive industry

Looking for ways to stay ahead or need a competitive edge in the ever-changing automotive industry? Want to expand your automotive solutions knowledge? You‘ll see the latest advancements at the ZEISS smart factory display during our eMobility and car body solutions technology day.

At this event, you'll learn from Capture 3D subject matter experts how ATOS structured light fringe projection technology collects accurate 3D measurement data from individual parts to create a reliable digital twin for use in digital assembly analysis to measure form, fit, and function. By improving collaboration and communication through meaningful data visualization that enables quick and confident corrective action, ATOS technology reduces costs, eliminates iterations and rework, and streamlines the entire product life cycle from development to production to achieve a modernized lean manufacturing strategy.

At this event, you'll learn from Capture 3D subject matter experts how ATOS structured light fringe projection technology collects accurate 3D measurement data from individual parts to create a reliable digital twin for use in digital assembly analysis to measure form, fit, and function. By improving collaboration and communication through meaningful data visualization that enables quick and confident corrective action, ATOS technology reduces costs, eliminates iterations and rework, and streamlines the entire product life cycle from development to production to achieve a modernized lean manufacturing strategy.

Capture 3D will explain how to:

- Quickly create a digital twin derived of accurate 3D measurement data

- Interact with 3D measurement data in intelligent software that features PMI/MBD import to enable inspection analysis, digital assembly, data visualization, and reporting, and integration into MES platforms

- Leverage automated data collection methods to support increased speed, throughput, and repeatability

- Unlock the power of full data capture for smart manufacturing strategies using advanced 3D measurement technologies for accurate and automated analysis

- Use digital assembly analysis to quickly make changes within design, tooling, functional build, and production processes to optimize engineering and manufacturing workflows

ZEISS Technology Day Agenda

Morning Session: eMobility Solutions | 8:00 to 11:30 a.m. ET

During this 3-hour session, our team of application experts will demonstrate our NEV solutions to enable you to be more productive and improve the quality of your products.

- Understand How X-ray Inspection Works with Battery Components

- Speed Up Quality Inspection with Live Extended Depth of Field Imaging with Microscopes

- See How New CMM Technologies Can Accelerate Inspection and Gather More Data Than Ever Before

- Explore Multi-Sensor Methodologies for Inspection of Flexible Materials used in E Motors and Fuel Cells

- Improve R&D of NEV Components with Surface and Form Inspection

- Transform Your Measurement Data into Meaningful Results with Real-time Visualizations and Correlated Measurements

Afternoon Session: Car Body Solutions | 12:30 to 4:00 p.m. ET

The afternoon session focuses on how to affect real process control utilizing relative or correlation-free measurements. From the metrology room to inline inspection, the goal is to increase throughput while getting meaningful results that you can trust.

- Take Measurements Inline for Real-time Process Monitoring and Part Quality Assurance

- Remove Human Subjectivity by Automating Defect Detection Early in the Manufacturing Process at Stamping and BIW

- Maximize Line of Sight and Reachability of Part Measuring through Modular Fixturing Systems and Strategies

- Enable Precision and Productivity Inline, At-line or Off-line without Reference Points and Correlation

- Augment Traditional Inspection Tools with 3D Scanning to Save Time in Product and Tool Development

- Digital Transformation Strategies Using Blue Light 3D Scanning Technology to Enable Fast Problem Solving, Intelligent Data Visualization, and Improved Communication