Best Uses of 3D Scanning and Its Applications

3D scanning is a technology that is changing manufacturing and engineering processes in every industry. The 3D scanning market is projected to reach $5.9 billion by 2013 (Source: MarketsandMarkets). Given this statistic, it’s easy to see that understanding 3D scanning technology and the impact it can have on your business will help you retain a competitive advantage. In this article, we will dive into the topic of 3D scanning software. We will start with a primer on 3D scanning and 3D scanning software, then review some of the most common use cases and 3d scanning applications for the software. If you’re already familiar with the subject and are just looking for a variety of 3D scanning software options, feel free to jump ahead to the Getting started with 3D scanning software section.

What is 3D scanning?

3D scanners are similar to their 2D counterparts in that they take a physical object in the real world, and digitize it into a format that can be saved, shared, and edited on a computer. Once in their digital twin format, the 3D models made possible by 3D scanners help enable engineering, design, and quality assurance efforts in a variety of industries.

Some of the components found in 3D scanners, like cameras and lasers, will be familiar to anyone with a topical understanding of modern technology. What differentiates a 3D scanner from a normal camera or 2D scanner is the level of precision and accuracy 3D scanners provide. Digital scanning technology like that found in the GOM ATOS Triple Scan can measure millions of points in a single measurement with a high level of precision (measured in microns, for reference 1 micron is 0.001 millimeters) and often complete a scan in a matter of seconds or minutes depending on the size of the job. What is even more impressive is that these scanners can retain this high level of precision on objects ranging from very small (a fingerprint for example) to extra-large (an aircraft).

If you would like to take a deeper dive on the technology behind 3D scanning, check out our What is 3D Scanning Knowledge Center and 3D Scanners With Blue Light Technology articles.

Where does the software come in?

While the scanners themselves are impressive instruments, the associated scan software is what enables end-to-end workflows that optimize precision, results, and quality from the beginning of a project to its conclusion. For example, our ATOS Professional software offers a simple Graphical User Interface (GUI) that enables users to complete tasks like sensor head operation, 3D point cloud processing, post-processing of data, and polygon mesh generation and editing. Additionally, ATOS Professional has a number of smart features like self-monitoring (which verifies calibration status, accuracy, environmental changes, and part movement) and dynamic referencing (which enables the part or the sensor to be moved during the scan without compromising accuracy or quality) to ensure that you are able to produce quality 3D models with a high level of precision in a repeatable fashion.

In short, the scanning hardware is what makes the digital representations possible, and the scanning software is what enables you to work with the digital representations to achieve your goals. You can learn more about ATOS Professional Software and see a video of the software in action here.

Common Applications for 3D Scanning Software

Now that we have given you a brief overview of the scanning hardware and software that make 3D scanning possible, we will dive into some of the common use cases for this powerful technology.

Quality control

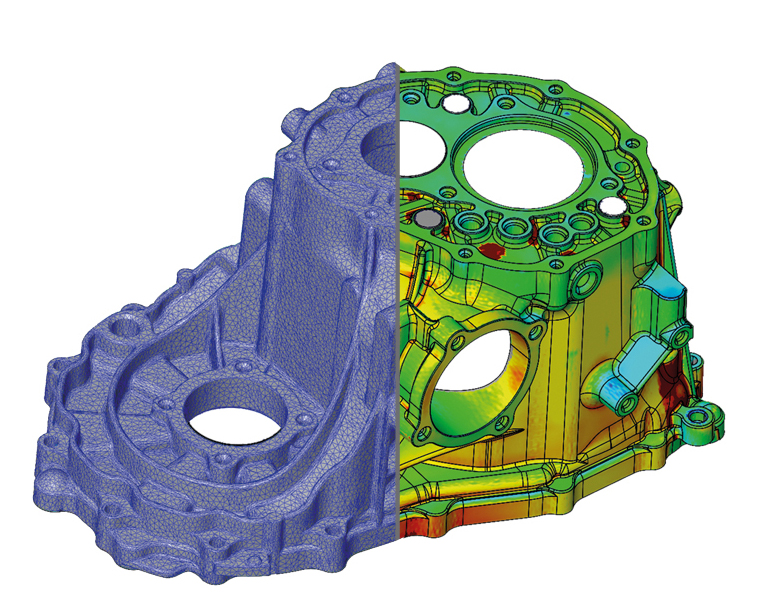

One of the most common 3d scanning applications for scanners and software is quality control. In today’s highly competitive markets where each company is striving to produce the most accurate parts in the fastest amount of time, quality control is of the utmost importance. High-quality manufacturing processes can distinguish a business from its competitors, and this makes precise, accurate, and repeatable quality control processes a vital part of any manufacturing plan. 3D scanning software can help firms improve the quality and speed of their inspections by creating detailed 3D models of manufactured parts and offering workflows optimized for specific industries. Each part can be scanned and the digital model can be evaluated to make sure every area on the part is within the specified tolerances.

Our ATOS inspection software enables users to inspect CAD (computer-aided design) files, 2D drawings, and multiple parts. Additionally, the inspection software offers CMM (coordinate measuring machine) style reports and color maps that enable quality engineers to immediately identify parts that are outside of specified tolerances.

Prototyping & 3D printing

Prototyping and 3D printing is another frequent use case for 3D scanning software. 3D scanners enable you to take a physical product, scan it into a digital format (e.g. the STL file format), and work with the digitized model to create prototypes that are then printed by 3D printers. The high level of precision enabled by quality 3D scanners significantly streamline this process because increasing the granularity of scan data greatly reduces the manual time required to create a solid model.

Reverse engineering & CAD creation

A very common challenge in the world of engineering and product design is reverse engineering a physical product for which you do not have a CAD file. Using a 3D scanner that will capture the complex geometric characteristics of a given part is a great way to develop a CAD file when one is not available. Creating or sourcing high quality CAD files early on in the reverse engineering process can greatly improve the results of the project by minimizing wasted time and guesswork based on inaccurate data. Time and time again Capture3D customers have found that the ATOS scanner’s rapid and easy workflow has minimized CAD creation time and led to more successful reverse engineering projects.

CFD/FEA

CFD (Computational Fluid Dynamics) simulation is commonly used for flight and wind tunnel testing. FEA (Finite Element Analysis) is often leveraged to predict how a given part or product will react when exposed to forces like heat, fluid, vibration, etc. As these simulations and analyses are used to simulate conditions for industries like aerospace where safety is of the utmost importance, precise digital models are a must, and this is where 3D scanners and the associated scanning software comes in. The more accurate the 3D models, the more reliable the simulations.

One example of a company using 3D scanning software for CFD is the case of the North American Eagle project which challenged the 763 mph world land speed record.

Getting Started With 3D Scanning Software

Now that you have an idea of some of the common use cases for 3D scanning software, you may be wondering how you can get started using it. We offer a variety of software solutions including the free GOM Inspect Software (download available at the link). The free software offers a variety of features and benefits and has been downloaded over 115,000 times. This inspection software has been tested and certified by American and German measurement labs (NIST & PTB) and placed in “class 1” (the class with the smallest deviations). It is a great way to get started with 3D scanning software and a useful tool to share with customers, vendors, and colleagues when working on a project.

In addition to our free software, we offer a number of premium software products designed to help you maximize your 3D scanning investment. Here is a quick breakdown of the premium 3D scanning software products:

-

GOM Inspect Professional- Includes all the features of the free GOM Inspect software and adds a variety of features like parametric inspection, support for native CAD formats (e.g. Solidworks & Pro/E), and personalized report pages.

-

ATOS Professional- Is an intelligent 3D metrology software for ATOS 3D scanning systems that includes all the features of GOM Inspect Professional as well as additional features such as: sensor control, polygon mesh generation and editing, and primitive generation.

-

TRITOP Professional-Is software used to analyze images from the TRITOP photogrammetry measurement system. This advanced software can display contrast lines and includes 3D coordinates.

-

Virtual Measuring Room (VMR)- Is a software module based on ATOS Professional that enables full measurement process simulation and includes collision detection & inspection features.

Still have questions? Ask the 3D scanning experts!

At this point, you may have a number of ideas about how 3D scanning software can benefit your business but are not sure where to start. Our dedicated team of experts at Capture 3D are ready and willing to help you find the right 3D scanning solution to help push your business to the next level. Our solutions feature workflows that are optimized to specific industries and we can help you select the best solution for your unique use case. Contact us today to learn more!