The Best Industrial 3D Scanners for Accurate Measurement, Inspection and Digitalization

The digitized future of manufacturing runs on data. From digital twin applications to Quality 4.0 initiatives, the key to unlocking successful lean and agile manufacturing strategies is accurate data. Thousands of companies trust our metrology-grade 3D scanners to collect accurate 3D data that delivers more than fast measurements— they deliver digitalization.

As the most innovative optical measuring system for 3D coordinate measurements on the market today, our industrial 3D scanners create opportunities to tap digital engineering capabilities. Engineered with advanced hardware and intelligent software for repeatable and accurate measurements, our high-resolution 3D scanners provide flexibility and process reliability. Their ability to measure different object sizes, surface finishes, and shape complexities is one of the many reasons they are accepted and widely utilized in various industries.

This technology has various names, such as optical measuring machine, optical 3D scanner, white light 3D scanner, blue light laser scanner, and non-contact 3D scanner. There are also many common misspellings of the word. But no matter what you call it or how you spell it, our 3D scanners provide the same results— data quality you can count on.

Our optical coordinate measuring machines (CMMs) utilize non-contact technology. These high-tech industrial 3D scanners provide precision scan data in detailed resolution in as fast as 0.2 seconds per scan. With this data, you can improve workflows, immediately solve quality issues, eliminate unnecessary iterations, optimize processes, reach tighter part quality standards and increase your overall competitive advantage.

Types of 3D Scanners

- Triangulation 3D scanners:

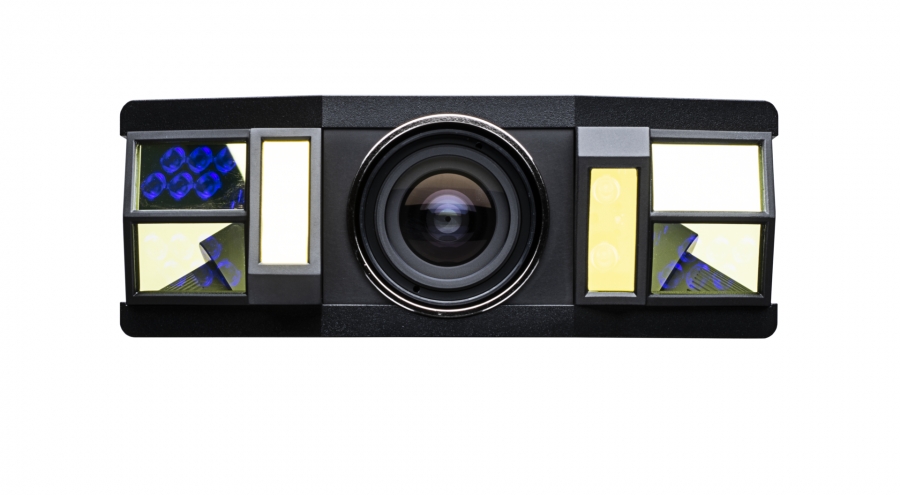

Our line of ATOS blue light 3D scanners use the principle of triangulation. In this principle, the sensor projects a fringe pattern across the part’s surface, and as the patterns shift rapidly during each scan, the two cameras on each side of the sensor capture the distortion to calculate the 3D coordinate measurements. This method results in full-field data collection, delivering millions of points per scan. With complete data of volumetric areas, you gain access to more information about your part.

- Structured Light 3D Scanners:

If you’re looking for a fast way to digitize your parts in high-quality data, structured light 3D scanners are among the best 3D scanners to use. Structured light 3D scanners engineered with blue light fringe projection technology capture the entire surface of your part, delivering a detailed digital twin quickly. Some structured light 3D scanners utilize the principle of triangulation, while others use the stereo camera principle. The stereo camera principle combined with fringe projection technology allows the sensor to recognize and compensate for environmental changes during scanning. Intelligent software operates our 3D scanners, continuously monitoring the status of the environment and measuring conditions to ensure high-quality data collection.

- Handheld 3D laser scanners:

Handheld 3D laser scanners are designed for portability, allowing the user to move the scanner to the object rather than moving the object to the scanner. With three different light sources available, our compact and lightweight handheld 3D laser scanner captures accurate 3D measurement data from a variety of parts in a variety of different environments. One of the most significant advantages of using a handheld 3D laser scanner is gaining the ability to capture measurements in tight or difficult-to-reach areas. For example, some technicians bring a handheld 3D laser scanner inside of an aircraft to scan areas needing repair.

- Photogrammetry:

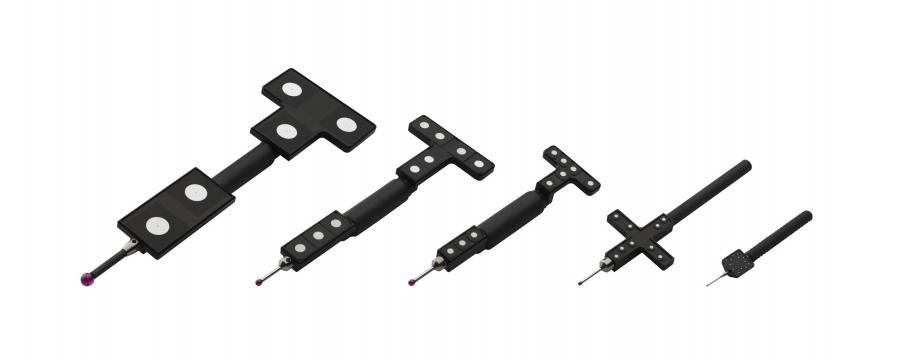

Photogrammetry is a type of non-contact optical 3D coordinate measuring system (CMS). Ideal for measuring large-scale objects accurately, photogrammetry uses a single high-end camera to capture precise 3D coordinates in quick snapshots. Digital 3D photogrammetry technology produces accurate coordinate measurements for fast dimensional inspection, verification, and deformation analysis. By snapping photos from various angles with reference markers and utilizing the principles of triangulation, precise points are calculated onto the 3D coordinate plane.

Maintaining exact camera positions during the process of collecting 3D photogrammetric measurements is not necessary because the reference markers serve as a guide during postprocessing. Some coded measuring markers are applied to the fixture or directly to the object and are used for the automatic evaluation process. Scale bars are positioned next to the object. Their dimensions are transferred to the measurement to provide scale and to observe the measuring accuracy. Surface points to be measured have to be marked with removable markers or adapters. The thicknesses of these markers are precisely known within the system. You can also mark points or sections with a pen. Image processing algorithms accurately determine each point or line drawn. The camera images are automatically transferred to the computer using a high-speed wireless network or flash card reader. From there, the computer completes dimensional analysis, and you can begin evaluations.

Common 3D Scanning Applications

If you work with the following, our 3D scanners can improve your product quality, workflows, and cycle times, helping you achieve a faster time to market:

- Inspection and quality control

- Reverse engineering

- 3D printing and rapid prototyping

- CFD/FEA analysis

Benefits of Accessing Digitalization with Accurate 3D Scanners

One of the benefits our accurate 3D scanners provide is the ability to collect millions of X-Y-Z coordinate points from an object’s surface in a few seconds. You can use the resulting geometric digital twin to compare against the CAD model with a 3D inspection color map displaying a spectrum of colors that signify areas in or out of tolerance. This visual data analysis fosters improved communication and collaboration throughout your organization. The digital twin provides many other benefits, including simulation capabilities, digital assembly, virtual assembly, comprehensive analysis and keeping a digital record of a physical part that you can archive to refer back to later.

Working with our 3D scanners is fast and easy. Setup is minimal and does not require specialized programming skills or highly accurate fixtures. In as fast as 0.2 seconds per quick scan, our 3D scanners reveal discreet problematic areas that would have been undetected by traditional measurement methods. By digitizing an entire object, part, mold, tool, or die, you’re removing uncertainty and quickly identifying problems so you can swiftly and confidently apply their solutions. This ability to move quickly with more information allows you to eliminate iterations and save time and money that were once lost to rework.

Other benefits of using our accurate blue light 3D scanning solutions include:

o Highly accurate traceable 3D measurements

o Detailed high-resolution data

o Quick data collection

o Advanced parametric inspection functionality

o Digital engineering capabilities, including dimensional analysis, GD&T, trend analysis, digital twin applications, industry-specific inspection functionality, and more

o Comprehensive reporting with data visualization for faster actionable insights

We know you’re looking for the best 3D scanner, so contact us to help you discover which is best for your application. We look forward to learning about your requirements and challenges so we can help you reach your goals.