Metrology within the Stamping Industry

Utilizing: ATOS 3D Scanners, TRITOP Photogrammetry, Software, and/or Automation

With rising global competition and the need for efficiency, stamping companies utilize Capture 3D metrology solutions to maintain their competitive edge. Optimizing stamping engineering processes are important, so cycle times can be reduced while saving costs on manufacturing and speeding up time to market. Capture 3D metrology solutions are utilized throughout the stamping industry.

Some examples include:

Design

|

Design / Re-creation of Dies and PartsQuickly scan dies and panels to generate an accurate 3D digital definition to support CAD model creation, documentation of design iterations, and archive “as manufactured” condition. |

|

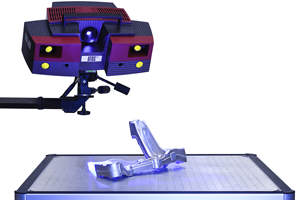

High Resolution & Detailed ScansATOS scan data captures intricate details and fine lines for organic and complex part geometries. |

|

Small Parts ScanThe ATOS 3D scanner’s ability to be configured to various size measuring volumes supports the precise scan capture of very small features. |

|

Extra Large Parts ScanMeasure large parts (i.e. castings, airplanes, etc...) while maintaining a high level of data accuracy. ATOS system flexibility supports extra small to extra large scan projects. |

Analysis

|

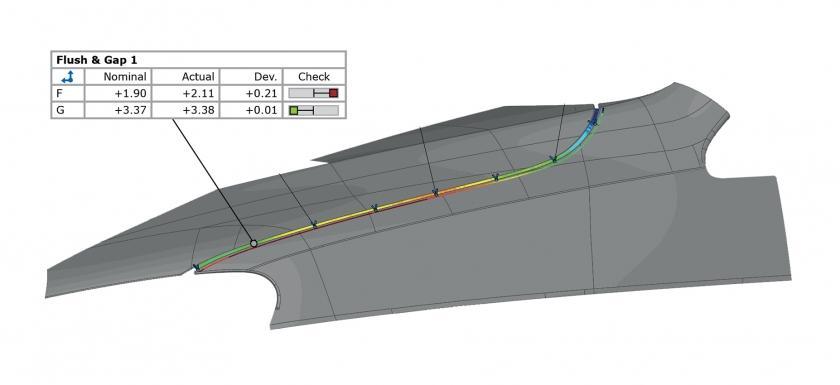

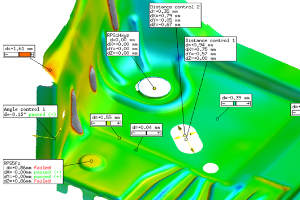

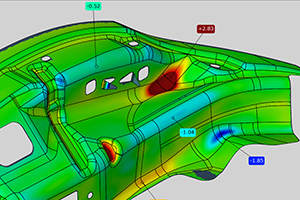

Die & Panel InspectionSpeed up try-out & production processes by quickly scanning & inspecting stampings to insure part & tool quality with easy to understand pictorial reports. |

|

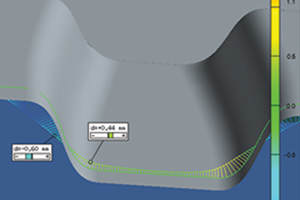

Spring Back AnalysisDecrease try-out cycle time by accurately measuring & quantifying spring back characteristics. |

|

As Built vs. As DesignedRapid generation & complete coverage for 1st article inspection. Full color map report is a benefit over traditional & portable CMM deliverables. |

|

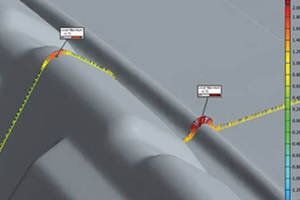

Determine ClearanceSpeed up die analysis without placing the die in the press or having to remove the die from the press to determine clearance & interferences by digital spotting. |

Production

|

Root Cause & Trend Analysis

Determine the cause of manufacturing issues and predict future trends by quickly capturing “as built” tooling conditions for various types of analysis. |

|

Digitizing Raw CastingsDecrease the roughing process by 50% via direct milling from scan data (STL). Optimize & reduce machining time by avoiding part collision & “cutting air” by using the raw casting scan (STL) data as the work piece. |

|

Finger Printing of DiesThoroughly & accurately capture the geometry of the die after the try-out process. Data supports CAD modeling, duplication, & archiving. |

|

Die Duplication / Copy MillingReduce time, costs, & meet increased production requirements via die duplication & mirroring. Machine directly from the accurate scan data (STL) of the production tool. Eliminates CAD modeling. |

|

Elimination of Check FixturesSave time & money by eliminating costly check fixtures by utilizing less expensive holding fixtures. Digitally capture your nominal inspection points and features. |

Related Case Studies

Categories: Stamping