Jabil Greenpoint

Process Control in Mass Production of Consumer Electronics

Jabil Greenpoint is the world's third largest electronic manufacturing service provider with over 21 million square feet manufacturing and over 60 sites on four continents. This presentation will look at their injection mold inspection process using ATOS in comparison to a CMM.

From mobile phone to tablet PC: an expert from Jabil Green Point will be explaining how reliable quality control of mass produced consumer electronics works. The company from Taiwan produces parts and electronic components for mobile phones and other portable electronic devices. Green Point belongs to the American Jabil group, with more than 60 factories in 33 countries worldwide, Jabil is one of the largest producers of electronic components for industries such as aerospace, automotive, consumer products, telecommunications and medical technology.

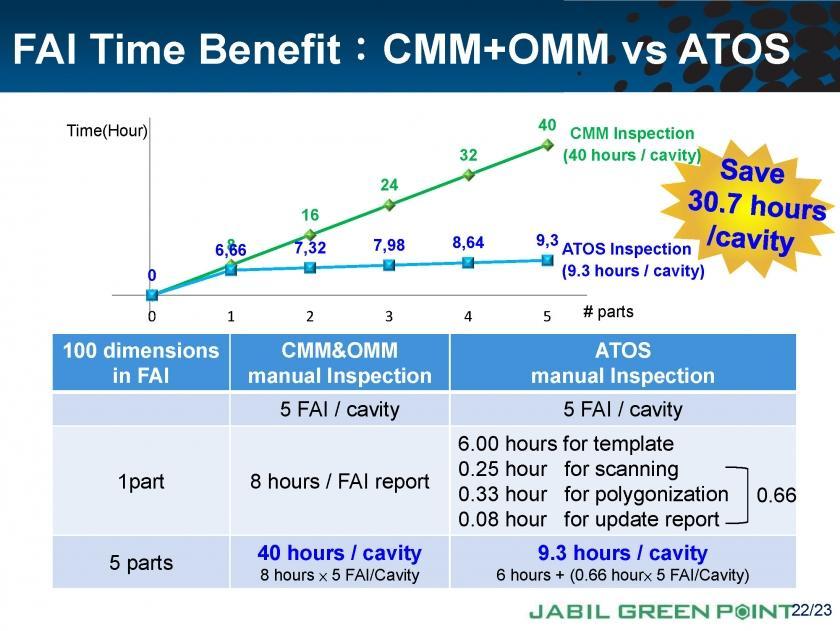

The presentation from Jabil Green Point shows how the quality of mass produced parts can be efficiently and reliably checked with the help of optical metrology, and how GOM's optical 3D scanners are being implemented not just to analyze parts but also directly on the tools.

This presentation was given at the GOM International Conference in 2013. To receive a copy of the entire presentation, please fill out the form below or email .