News

Read the latest news about CAPTURE 3D.

CAPTURE 3D is entering into the key stages of its post-merger integration within ZEISS Industrial Quality Solutions. Over the next several months, CAPTURE 3D will transition into ZEISS Industrial Quality Solutions, with the CAPTURE 3D brand retiring in September 2024. We are excited about what the future holds and are grateful to have you here as part of it as we become ONE ZEISS— an even more unified, modern, innovative, and customer-focused team.

CAPTURE 3D debuts the new ZEISS INSPECT 3D metrology software developed to solve modern manufacturing and engineering challenges and improve processes and productivity through digitalization.

For the first time in four years, CAPTURE 3D hosted its renowned Innovation Conference & Expo, bringing together hundreds from its community of manufacturing and engineering professionals with a common goal— to strengthen the future of manufacturing with 3D digitalization technologies, automation strategies, advanced software, and solutions that enable sustainability.

In October 2021, we shared the exciting news that the ZEISS acquisition of CAPTURE 3D had been finalized. For the past two years, behind the scenes, our teams have been working together on the post-merger integration to become ONE ZEISS – an even more unified, modern, innovative, and customer-focused team. As of October 1, 2023, CAPTURE 3D, LLC, and our team members will be transferred to Carl Zeiss Industrial Quality Solutions, LLC.

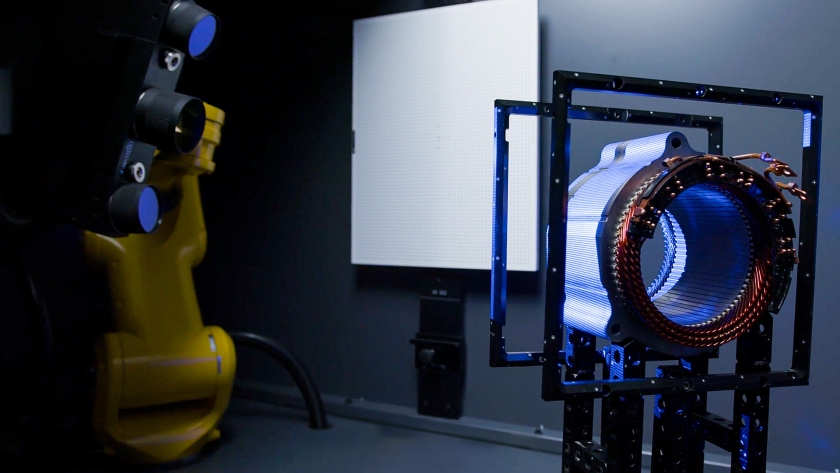

ZEISS ScanBox for eMotors is an automated 3D scanning and inspection solution for the fast and accurate digitalization of electric motor hairpin-stator assemblies and components to support efficient quality assurance.

CAPTURE 3D makes the fast digitalization of very large parts possible with the ZEISS ATOS LRX accurate 3D scanner.

The CAPTURE 3D Innovation Conference & Expo is returning for the first time since 2018, bringing together the manufacturing and engineering community to learn how advanced 3D metrology technologies enable digitalization to support a sustainable future for manufacturing.

CAPTURE 3D upgrades its portable 3D scanner offerings with the ZEISS T-SCAN hawk 2, a handheld 3D laser scanner providing speed and reliability to easily capture metrology-grade precision data for a wide range of applications.

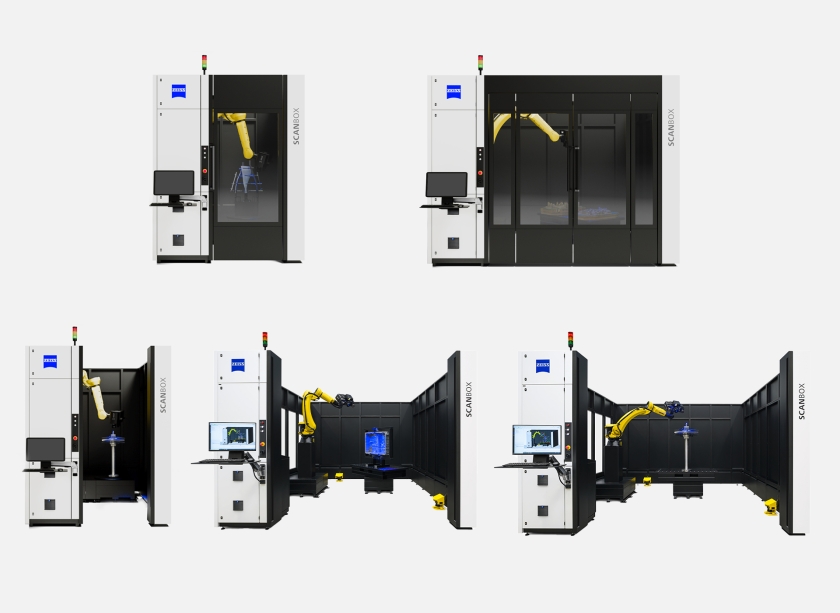

The ZEISS ScanBox Series 5 is a collection of turn-key intelligent 3D scanning and inspection robotic solutions designed to adapt to the changing needs of modern industrial environments.

The long-awaited return of the CAPTURE 3D Innovation Conference & Expo is here! For the first time since 2018, the biennial conference will take place following a hiatus caused by the COVID-19 pandemic. Mark your calendar for the week of October 2, 2023, and join us at the new ZEISS Quality Excellence Center in Wixom, Michigan.

Nearly 150 manufacturing and engineering professionals registered for "Digital Transformation of Production Control with ScanBox" to learn about the latest automated 3D metrology technologies, hear real-world use cases from industry-leading companies, and network with other professionals to exchange experiences, ideas and solutions.

GOM Scan 1 is a high-tech portable 3D scanner designed for the serious hobbyist or industrial engineer that needs to digitize small to medium-sized objects at an affordable price.

CAPTURE 3D enhances its selection of portable 3D metrology solutions with the ZEISS T-SCAN hawk handheld 3D scanner, offering fast and easy high-quality 3D data collection with the flexibility to measure tight or hard-to-reach areas anywhere.

GOM Suite 2021 ecosystem connects essential solutions in a single user-friendly software platform that addresses product development, quality control, manufacturing, and production challenges through enhanced data visualization and comprehensive analytics.

It's official– Capture 3D is now with ZEISS!

We have a BIG announcement – Capture 3D will join ZEISS!

The new GOM ScanCobot is an easy entry into metrology-grade automated 3D scanning. This affordable mobile measuring station combines a fully automated collaborative robot with ATOS blue light 3D scanners-- ATOS Q or ATOS Core-- for accurate and repeatable measurement results of small to medium-sized parts.

The new ATOS Q is a powerful compact 3D scanner that acquires high-definition and precise, three-dimensional scans of various objects ranging from small to medium-sized parts across diverse industries. It features interchangeable measuring lenses for flexibility and a sleek, modern design for portability.

Complimentary customer access to digital e-learning courses until May 31, 2020!

April 2020:

Dear Capture 3D Community,

We want to thank you personally for working with us, and it is our privilege to have you in our Capture 3D network. Today, we want to connect with you about what you can expect from us during this time. Facing a pandemic is something new to all of us, so now, above all, we must strengthen our support as a community to get through this together...

April 8, 2019 - A new case study written with Desktop Metal has been published. Despite its young age, Desktop Metal is making waves in the 3D printing industry. The company was founded in October 2015 by an all-star team of 3D printing experts with a common goal—making metal 3D printing more accessible by tackling the challenges in this area, including cost, quality, speed and safety.... In order to inspect and verify 3D printed parts, Desktop Metal needed a metrology solution as advanced as its technology. And with a broad customer base, Desktop Metal needed to be able to measure parts from multiple disciplines across the manufacturing industry—including aerospace, medical, automotive, and more. In addition, 3D printing is often used to create complex shapes and geometries unattainable with traditional metal manufacturing methods, so Desktop Metal needed to be able to measure these kinds of parts accurately as well.

March 6, 2019 - A new case study with ADAC Automotive has been published. ADAC Automotive first opened its doors in Grand Rapids, Michigan in 1975. Back then, the small company was known as ADAC Plastics. Today, ADAC Automotive is a tier-one automotive supplier that focuses on the production of vehicle entry systems, exterior and interior door handles, exterior trim and exterior mirrors for the global automotive market. In 2014, ADAC decided to explore 3D metrology systems - "[Adopting the ATOS 3D scanners] has been quite the shift... The 3D scanner has evolved from being a tool used to help in certain situations to being used every day.” The numbers prove it. In 2014, ADAC scanned 378 parts. In 2017, that number jumped to over 8,000 parts.

October 15, 2018 - A new case study with GE Appliances has been published that explains how the GEA team is redefining product development using cutting edge 3D metrology solutions with ATOS, TRITOP, and ScanBox to solve engineering challenges. “It was easy to make the business case to purchase the systems,” said Dave Leone, Director of Dimensional Control for GE Appliances. He noted that his team was instantly able to start driving improvements. Leone views the GOM systems as more than just a stand-in for the traditional CMM. He describes ATOS as a powerful engineering tool.

MIAMI – April 14, 2015 – A GE Aviation open innovation challenge designed to uncover new methods of conducting high-speed, automated inspections of turbine airfoils garnered 51 entries from 48 different participants in 18 countries. The winning entry was submitted by Capture 3D, of Costa Mesa, CA.