Doosan Skoda Power

Reverse Engineering - Retrofit and Modernization

Doosan Heavy Industries & Construction is part of Doosan Group - the oldest and one of the most successful conglomerates in Korea. Doosan Group is active in engineering and manufacturing of power plants, industrial facilities, desalination, engines, construction and construction equipment. This presentation will cover their ATOS and TRITOP usage for 3D scanning and coordinate measuring for reverse engineering projects.

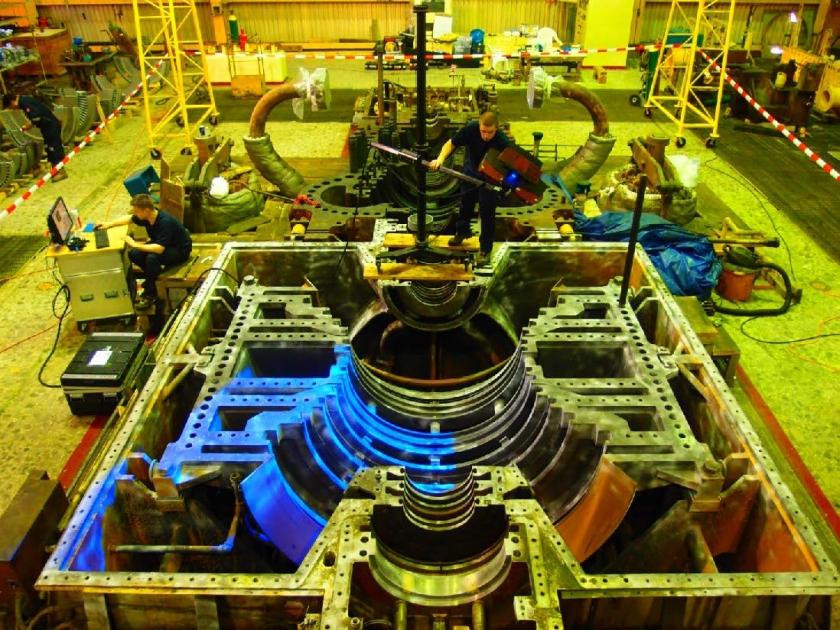

Doosan Škoda Power will demonstrate how optical metrology improves the efficiency of turbine modernization and retrofitting processes. The Czech company is a member of South Korea's Doosan Group, whose core competences lie in the area of machine, plant and infrastructure engineering. The focus of its energy business, Doosan Škoda Power, is on the production of steam turbines, turbine machine housing, heat exchangers and capacitors for power stations.

Modernization and retrofitting of turbines, both from its own production and from other manufacturers, is one of the company's key business segments. This complex process is optimized on the basis of optical measurement technology, with the ATOS 3D digitizer supplying precise measurement data of the components that are to be replaced, like, for instance, turbine blades. This 3D data forms the basis for CAD models, which are used to manufacture new components with great accuracy and at maximum speed. Additionally, optical metrology guarantees on-going quality controls. Manufactured components are analyzed with the 3D digitizer, and all results are verified against the CAD model. This rapid supply of precise measurement results ensures that turbines can be retrofitted without delay, and, at the same time, the obtained data guarantees the top-quality of all newly produced components.

This presentation was given at the GOM International Conference in 2013. To receive a copy of the entire presentation, please fill out the form below or email .