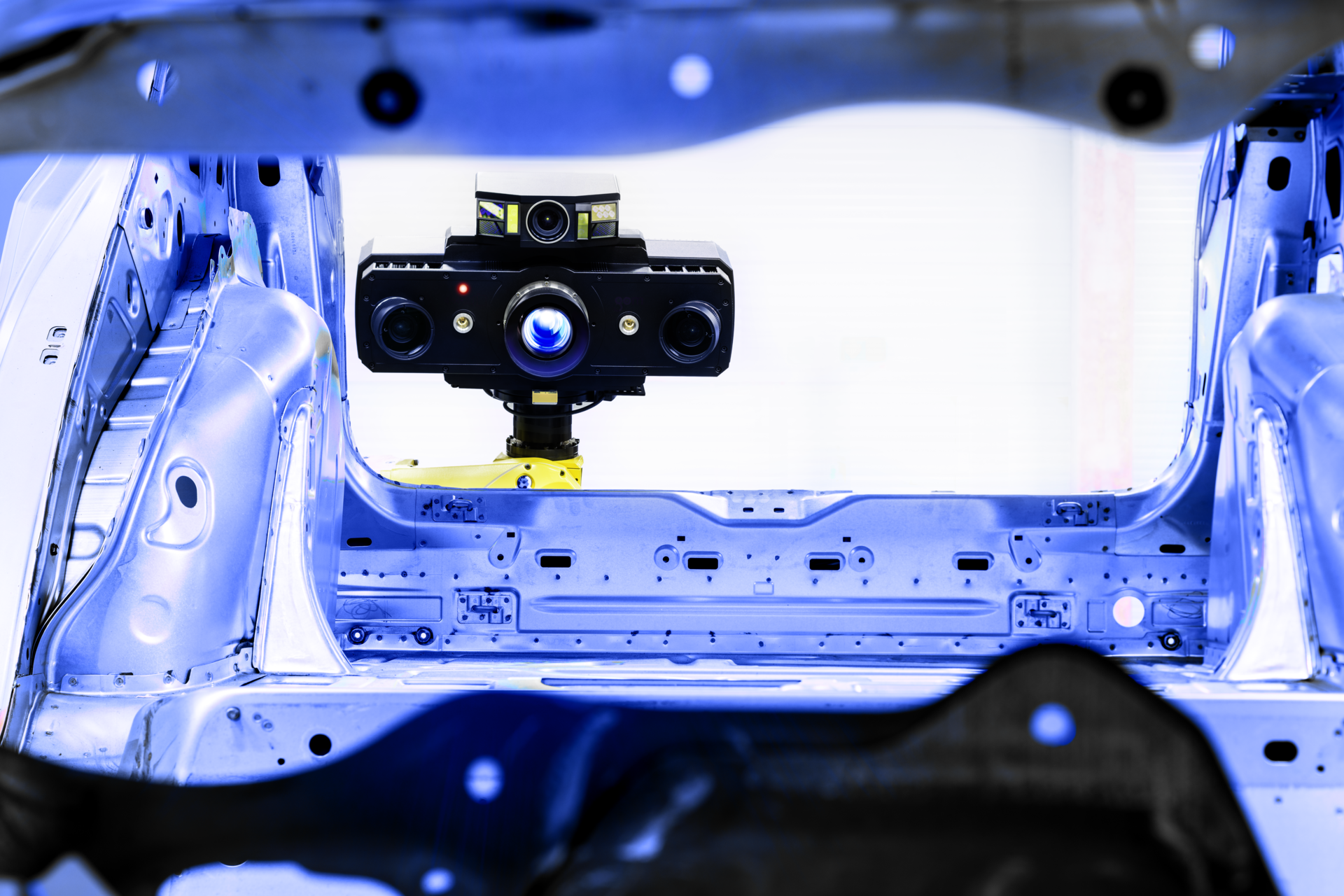

ATOS Plus (Add-on)

ATOS Plus (Add-on)

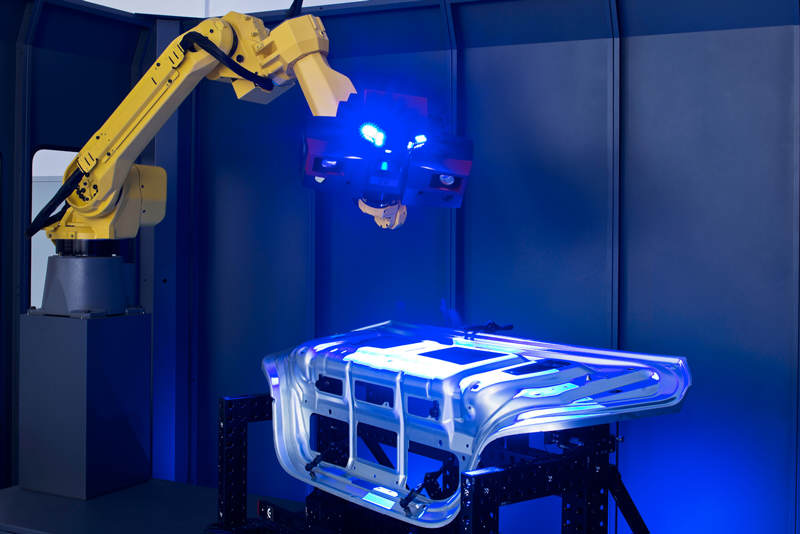

Integrate and Automate Photogrammetry with ATOS 3D Scanning for High Precision and Rapid Product Inspection Applications

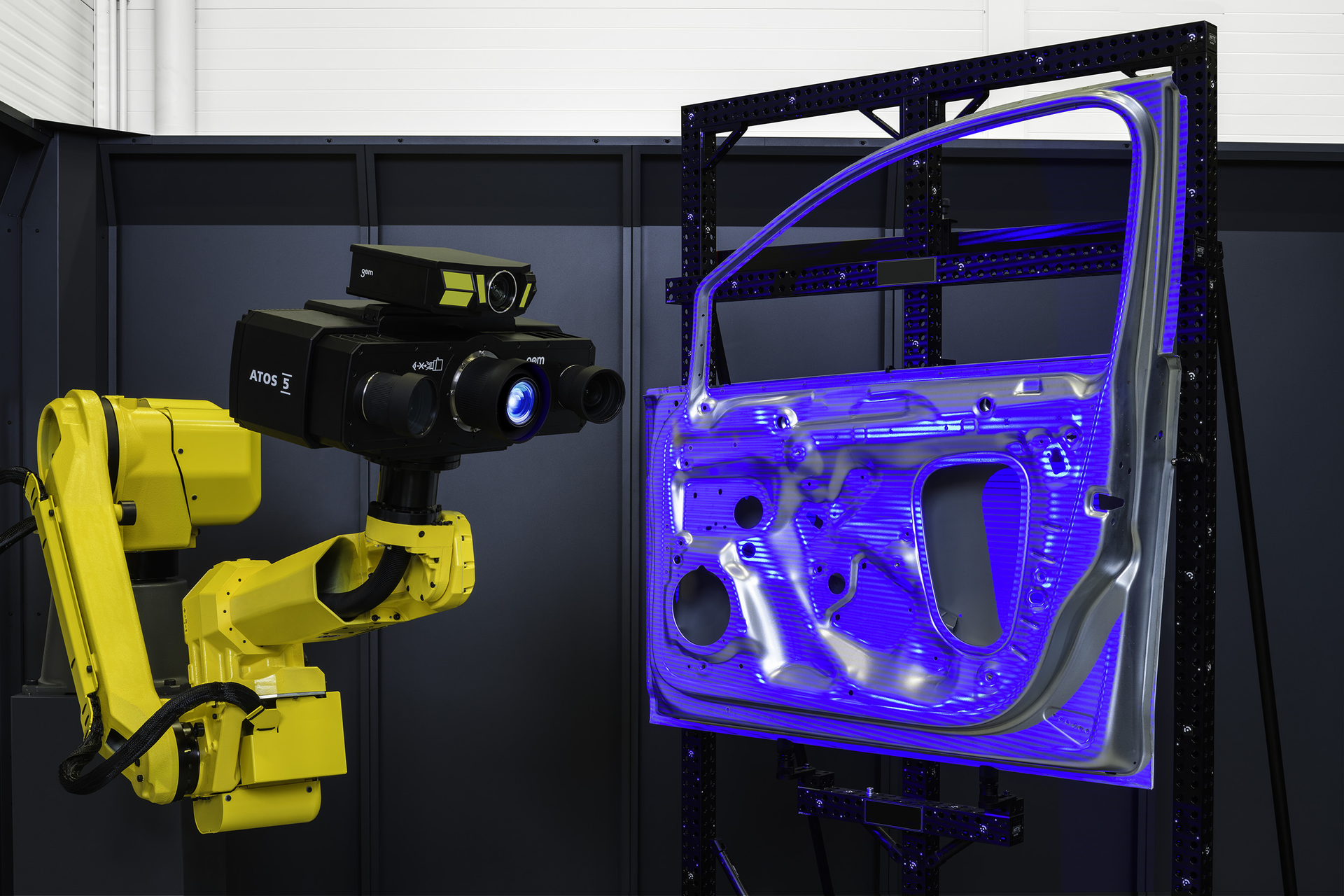

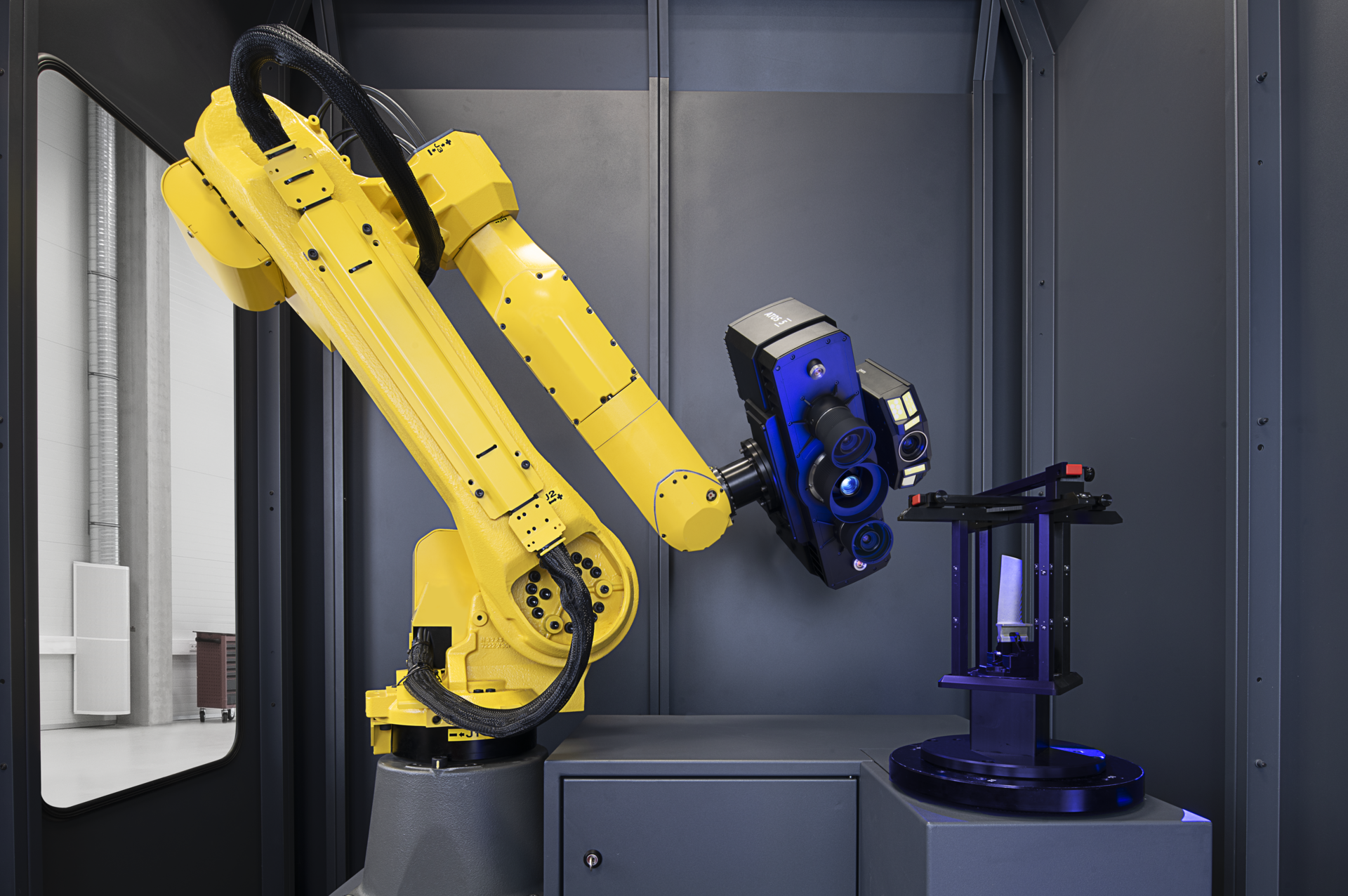

ATOS Plus intuitively integrates photogrammetry with ATOS sensors to further advance automation, dimensional inspection analysis, verification, and process safety with a touch of a button. This dynamic combination enhances measurement accuracy and repeatability and eliminates the need for costly precise fixtures. It streamlines the entire measurement process while decreasing the overall project time. With just the press of a button, ATOS automatically performs photogrammetry, 3D scanning, and inspection delivering accurate and rapid results. The built-in faceted illumination provides uniform lighting regardless of measurement area or environmental conditions. All ATOS Plus sensors are verified and certified according to VDI acceptance tests.

ATOS Plus features a high-resolution 45-megapixel camera. With ATOS Plus, a complete optimized, automated inspection process can be achieved:

-

- Precision accuracy with fast speed

- Process safety over long periods

- Higher repeatability and reliability

- Time-saving

- Reduced costs of fixturing

The ATOS Plus solution integrates into GOM's existing digitizing and inspection solutions. The Plus Box allows high accuracy, automated photogrammetry, and extends ATOS sensor heads.

{youtube}QsiaAfNgQiY{/youtube}

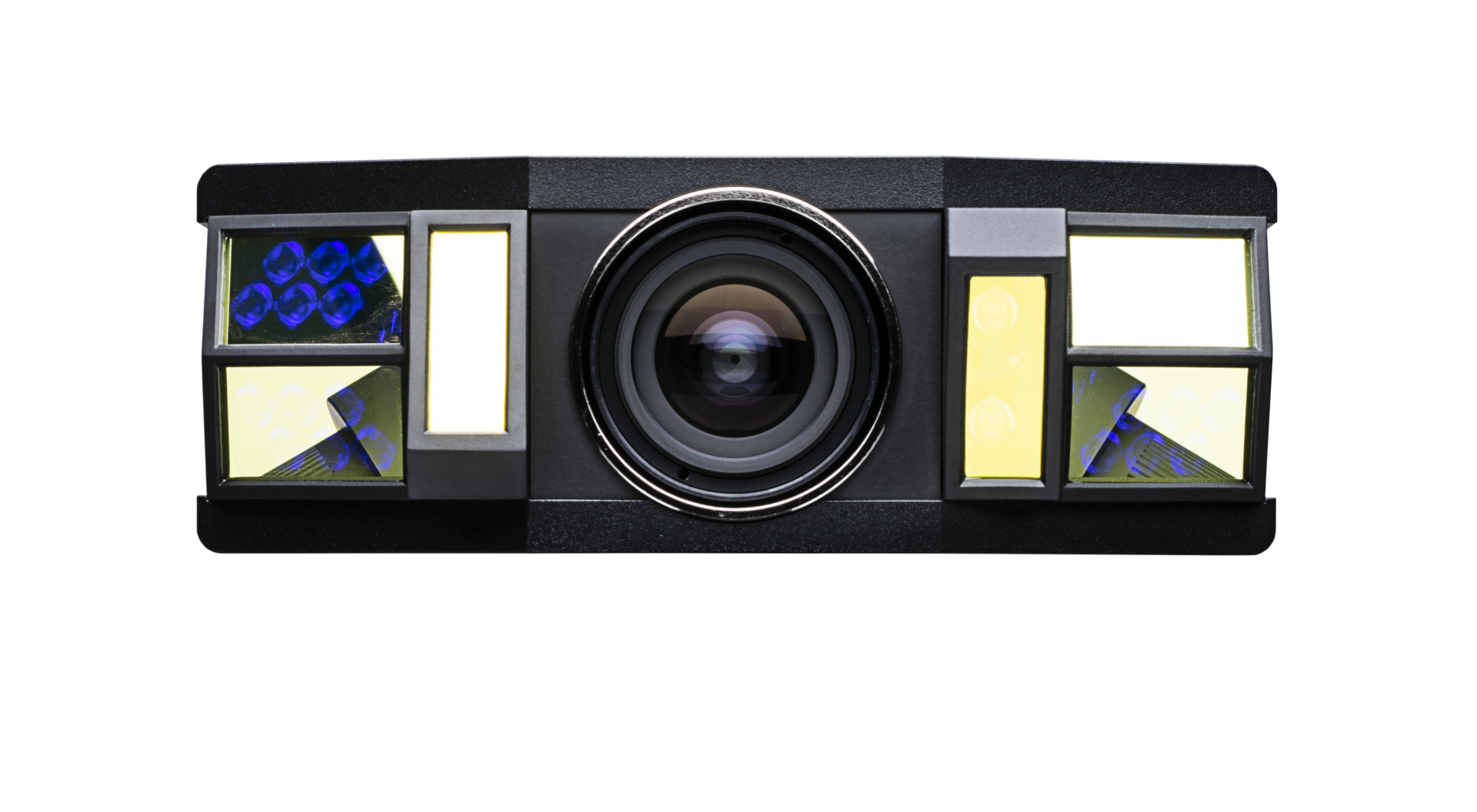

High-resolution photogrammetry cameraThe photogrammetry camera delivers 45-megapixel resolution capturing high accuracy reference points. The high-resolution sensor and special optics enable large measurement areas of up to 3m with short stand-off distances.

Process safety over long periodsThe accuracy of fixtures can be affected by a number of external factors, including temperature and mechanical influences, bumps and collisions as well as changes in the position of fixtures and parts in the course of time. ATOS Plus detects these changes automatically and triggers a new photogrammetry measurement. |

|

Higher repeatability and reliabilityThe Plus Box uses specially developed GOM optics and proprietary lens ensuring high imaging stability and measuring accuracy. All Plus Boxes are verified and certified according to VDI acceptance tests. |

|

Time-savingComplete integration into automated processes without manual intervention.

|

|

Reduced costs of fixturingFixtures and reference frames ensure that parts and components remain stable and fixed during the entire measurement process. ATOS Plus opens new possibilities for fixturing:

|

|

Technical Data

ATOS Plus 45M is fully integrated into GOM's existing digitizing and inspection solutions, including GOM Inspect Professional software, which provides direct control in the traceable software. ATOS Plus 45M sensors are tested with reference to the VDI/VDE 2634 guideline and can be easily mounted onto various ATOS sensors.

High-resolution photogrammetry camera

With a resolution of up to 45 megapixels, the built-in photogrammetry camera measures reference points with high accuracy. ATOS Plus 45M has an integrated dual reflector that ensures uniform illumination regardless of the measuring area.

Large measuring area

The high-resolution sensor and the special optics enable a large measuring area of up to 3 meters with a short measuring distance. The optics and projector lens of the ATOS Plus 45M are developed to ensure high image stabilization and measurement accuracy.