Industries - Advancing Concept to Production

Driving Progression and Innovation to Optimize Manufacturing.

Gain more knowledge about your manufacturing processes, so you can quantify what is actually going on to help solve engineering issues, prevent future problems, optimize workflows, eliminate wasteful iterations/rework, and improve product quality while accelerating ROI. Save time and reduce costs while speeding up your overall time to market. It’s that simple.

-

- Advanced 3D measurement technology

- Fast precision 3D coordinate measurements

- Accurate high resolution full part definition

- Rapid inspections with easy to interpret reports

- Intelligent software that is easy to use

- Customized automation solutions

- Accelerate ROI

Contact us for an onsite demo with your parts in your environment today.

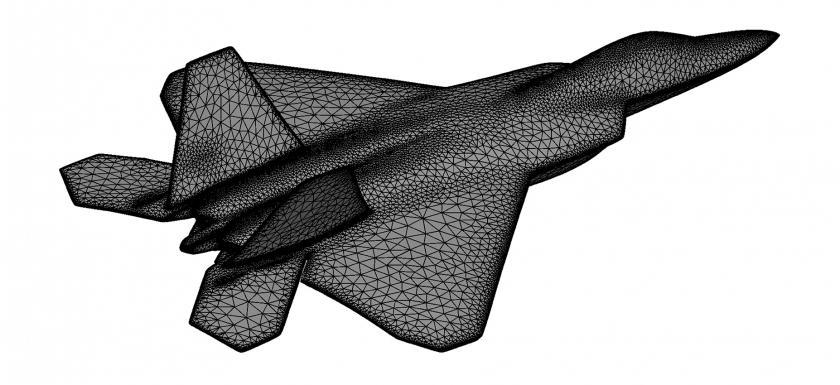

When building an aircraft for the commercial, defense, and space industries, the manufacturing is a labor intensive process which requires the capability to measure large structures quickly for fit, form, and dimensional validation accuracy. Turbine engines and sub-components, such as airfoils, turbine blades, blisks, stators, etc., require a high level of accuracy at rapid speeds especially during inline production. In order to reach these goals, companies are utilizing Capture 3D metrology solutions for various applications inside these industries.

- Design

- Analysis

- Production

- MRO (Maintence, Repair & Overhaul)

- Related Case Studies

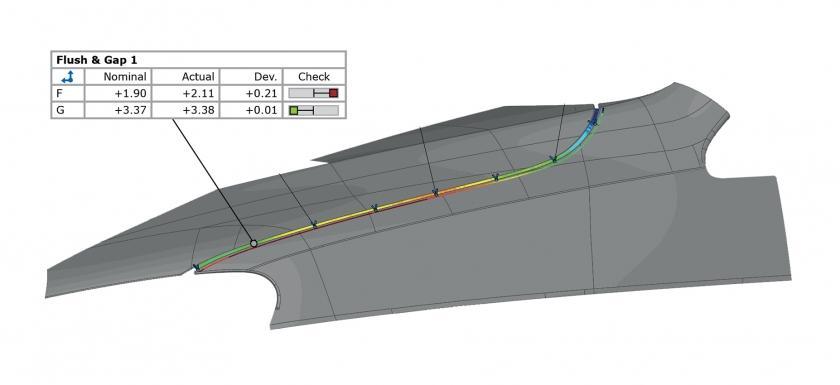

In order to meet today's demand for higher quality, faster, sleeker, and multi-functional vehicles, companies are advancing their design, engineering and manufacturing processes to help speed up product development to production.

- Design

- Tool Building

- Functional Build / Pilot Production

- Production

- Marketing

- Related Case Studies

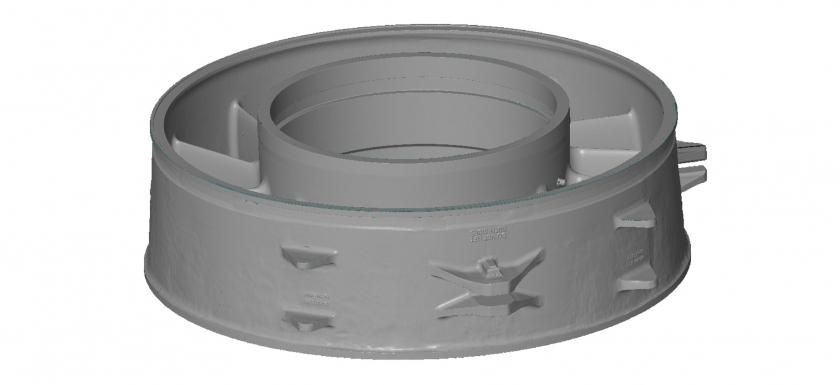

Casting manufacturers are striving to produce parts closer to net shape and meet tighter tolerance requirements. These industry demands are driving a requirement for quick, accurate, and more thorough part qualifications to ensure a final part exists within the casting or forging. Capture 3D metrology solutions are utilized throughout the casting and forging industry.

- Design

- Analysis

- Production

- Related Case Studies

In plastic and injection molding processes, 3D metrology supports and speeds up all phases in thermoplastic and injection molding: from prototype & tool construction to first article inspection reports through to assembly analysis and load testing. Full-field surface measurements guarantee faster sampling inspection and targeted tool correction, thereby reducing production lead times. Capture 3D metrology solutions are utilized in various processes to optimize plastic and injection mold manufacturing.

- Design

- Tool Building

- Analysis

- Production

- Related Case Studies

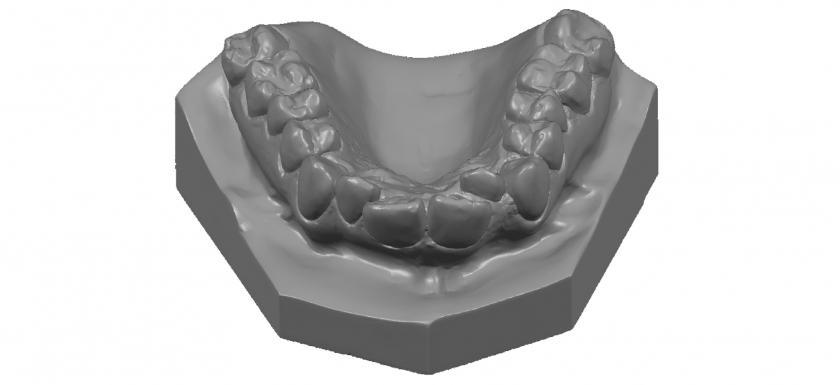

In medical and research industries, 3D metrology plays an important role to ensure parts are designed and manufactured to specifications. Accurate scan data allows doctors, researchers, and companies to dimensionally analyze components as well as reverse engineer to quickly make enhancements for modifications. Capture 3D metrology solutions are utilized throughout the medical and research industry for fast and precise product development.

- Research & Design

- Analysis

- Production

- Forensics

- Related Case Studies

With rising global competition and the need for efficiency, stamping companies utilize Capture 3D metrology solutions to maintain their competitive edge. Optimizing stamping engineering processes are important, so cycle times can be reduced while saving costs on manufacturing and speeding up time to market. Capture 3D metrology solutions are utilized throughout the stamping industry.

- Design

- Analysis

- Production

- Related Case Studies