Nerezine

Reverse Engineering - Boat Model & Form Making: 3D Measurement of GAJETA Using TRITOP

Modern technology simplifies and quickens the manufacturing of products having reproducible characteristics. In order to make it possible to create a faithful copy of the Nerezine boat, the Croatian company TOPOMATIKA performed a 3D measuring of the boat's shape using the photogrammetry system TRITOP of GOM.

The GAJETA is a small traditional fisher boat from Croatia. It is made of wood, approximately 7 to 12 meters long and was used in the Mediterranean Sea along the Adriatic coast for fishing and transportation between the islands. The boat excels by its rounded bow and stern, its high carrying capacity and its good navigability, especially on the rough sea. However, when less expensive plastic boats appeared that were mostly produced by foreign manufacturers, the number of authentic boats drastically reduced.

One of the few still existing Croatian shipyards, specialized in the construction and repair of wooden boats, is located in the small town of Nerezine on the island Losinj. Enthusiastic about the beauty and navigability of its 8 m long GAJETA, the Lekic family decided to restart the production of these wooden boats. They own a boat with excellent characteristics and have the infrastructure, the knowledge and the necessary experience in building wooden boats. Now, with the help of modern technology, they want to revive traditional boat building.

Making wooden boats is a big challenge. The boat's frame consisting of ribs, beam and keel defines the shape, the stability and the navigability of a boat. In the past, experienced craftsmen produced these wooden frames by guess and experience but with varying success.

A reliable method to create a good new boat was to copy a boat that proved to be successful. The ribs of the original boat were copied by stencils and their shape was transferred to the wood out of which the ribs for a new boat were produced.

Modern technology simplifies and quickens the manufacturing of products having reproducible characteristics. In order to make it possible to create a faithful copy of the Nerezine boat, the Croatian company TOPOMATIKA performed a 3D measuring of the boat's shape using the photogrammetry system TRITOP of GOM.

Approximately 300 reference point markers (adhesive paper with white points on a black background) were applied to the boat in order to exactly define the shape of the hull. Then, several images from various directions were recorded with the digital camera and loaded into the notebook PC. The TRITOP software automatically identified all reference point markers in the digital images with high accuracy.

After the reference point positions in all images are defined, the system automatically allocates the individual markers for the pre-orientation of the images and exactly calculates the 3D position of the reference points. Scale bars, the gauge length of which was ultra-precisely certified by an approved calibration office, provide for proper scaling of the measurement. The TRITOP computation results in numerous precise 3D measuring point coordinates in a global coordinate system.

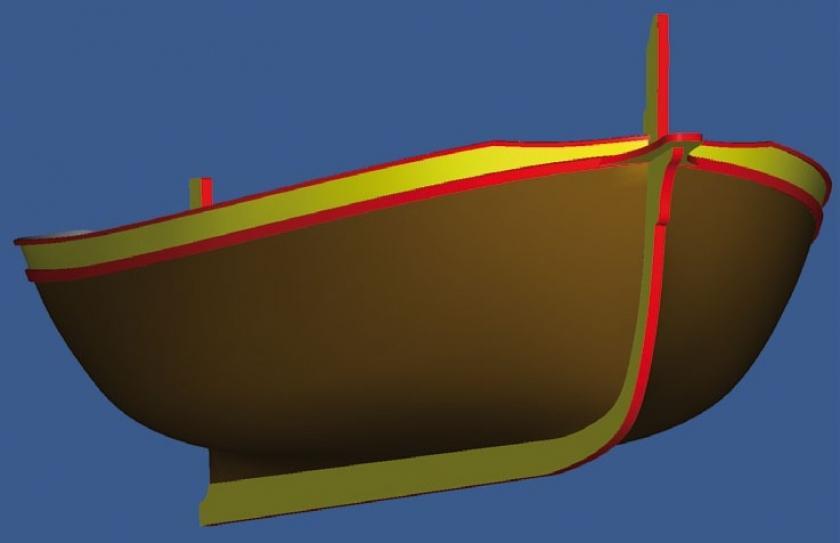

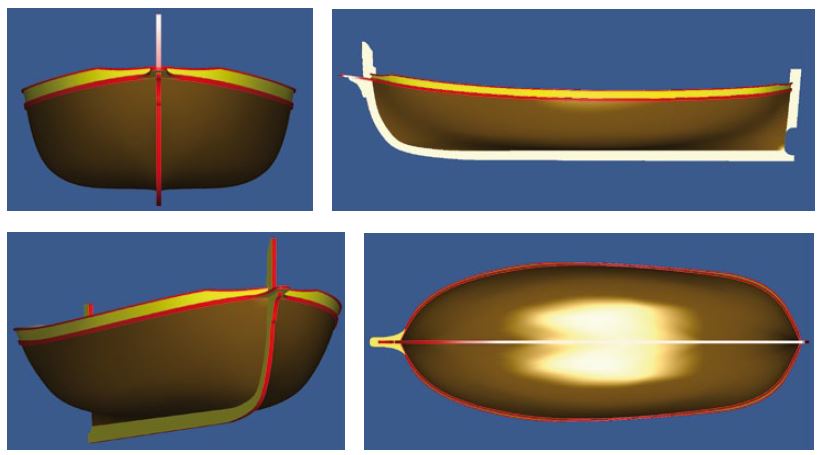

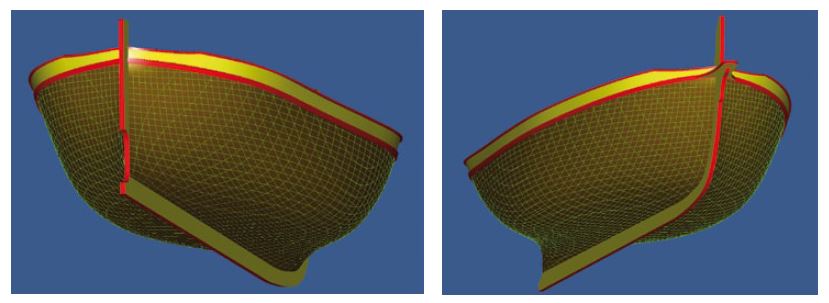

The position of the measuring points on the boat's hull (red points) and the camera positions during recording of the images (yellow). The yellow lines represent the lines of sight from various camera positions to one measuring point. The intersection point of these lines of sight defines the point's exact position in space. Such lines were determined for all measuring points but are not all shown here for reasons of clarity. The exact positions of the measuring points in space (coordinates X, Y and Z) define the 3D shape of the boat. Thus, the dimensions of the boat (e.g. its length) are determined as well. A software for surface reconstruction then defined mathematical surfaces spanning between the measuring points. These surfaces completely define the shape of the hull as CAD model.

This shows the calculated 3D model of the boat based on photogrammetrically measured reference points. The image illustrates the characteristic lines of the hull (parallel sections in all three planes).

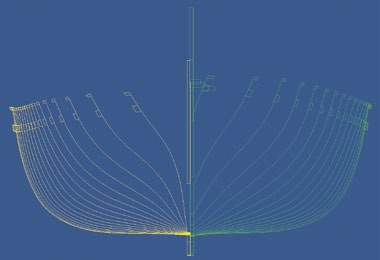

Now, it is easy to adapt the CAD model to customer-specific modifications. Based on the CAD data and the sections lines, the designer can easily and precisely define the ribs and other supporting elements of the hull. This shows the shape of the ribs and the position of the top hull edge. The green area (right side) shows the bow ribs, the stern ribs are displayed in yellow. A CNC milling machine may use the CAD data to directly cut the shape of the ribs into the wood. For small lots, the rib shapes defined in CAD are printed on a plotter, manually transferred to the wood and sawn out.

Measuring the hull using TRITOP is fast, flexible and precise. The created mathematical model of the boat is a faithful copy of the original. Customer wishes can easily and correctly be implemented and optimal planning and execution of production is possible.

We would like to thank the Nerezine shipyard for their trust in TOPOMATIKA and for the permission to publish this report.

Result of the photogrammetric measurement, the measuring points define the shape of the boat's hull