Reverse Engineering Applications

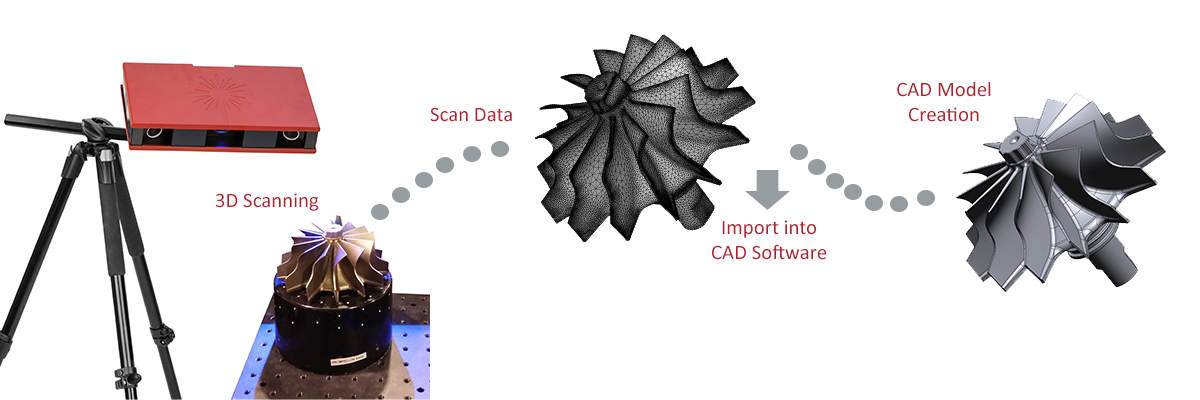

A key contributor in making reverse engineering an easier task is to start with accurate, clean, and high resolution scan data. It helps to utilize a 3D scanning system that will capture your part’s smallest and most complex geometric features. This will greatly aide in minimizing time and potential guesswork associated with the downstream processing. Starting with “bad or poor” quality scan data is like trying to get to a final destination with cryptic directions. Sure, you might be able to make it because of your navigational skills, but it will definitely take some time, effort, and frustration. Our reverse engineering customers have told us, because of the ATOS fast and easy physical to digital workflow and scan data quality, they have a precise and accurate foundation that minimizes their CAD creation time.

In simplest terms, 3D scanners measures the geometries of a physical part and brings it into the digital world. The data output is typically a point-cloud represented in STL (stereolithography) file format. This data is used throughout the design to manufacturing product life cycle for various applications: creating a CAD model, inspection analysis, reverse engineering, CFD/FEA analysis, rapid prototyping, and more.

Select an Industry Below to Learn More About Specific Applications