ScanBox: Automated 3D Scanning Technology

Commercial Off The Shelf (COTS) Automated Precision Inspection Solution for Rapid Deployment

|

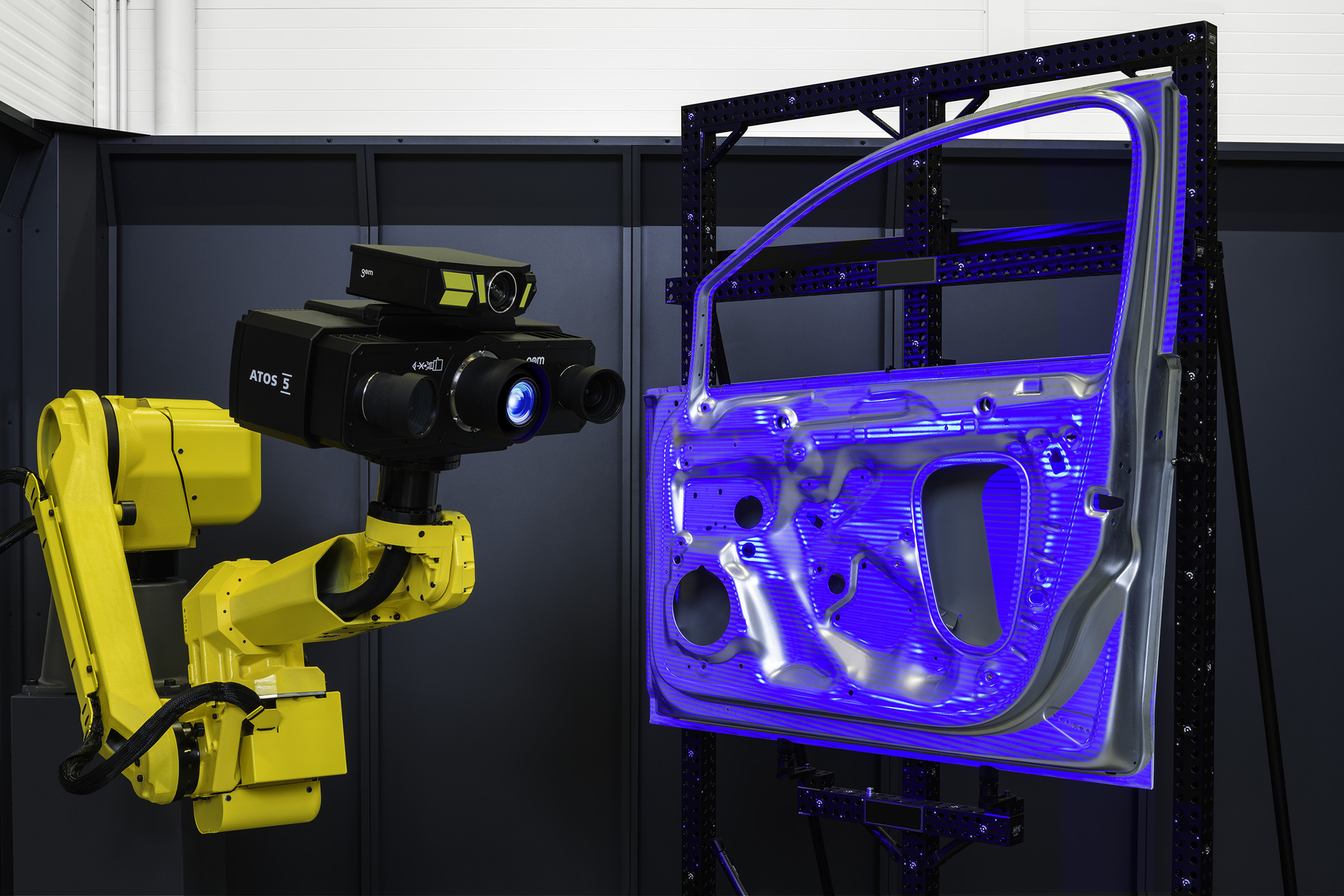

In industrial environments, automated 3D scanning inspection cells, also known as near-line or in-line coordinate measuring machines (CMM), have become an integral part of manufacturing and production processes. The ATOS ScanBox is constructed and engineered to industrial standards to assure the highest safety and mobility. Delivery time is short and setup is seamless. The ATOS ScanBox includes an ATOS 3D scanner, robot, rotary stage, software, safety house, and more. All the elements are in one box to ensure automation success and take advantage of the advanced digital twin technology.

- Accurate 3D coordinates with high-resolution data quality

- Rapid full-part scan with instant inspection analysis

- Full-field deviation to CAD, 2D and part-to-part

- Section-based analysis, GD&T and trend analysis

- Complete measurement reports

- VMR Virtual Measuring Room software module for advanced offline and online programming

Mobile automated 3D scanning inspection cell in a plug-and-play concept.

The compact ATOS ScanBox 4105 solution enables the fast and efficient digitalization of small and complex parts up to 500 mm^3 in size.

Modular concept for more versatility.

Designed to grow as your needs grow, the ZEISS ScanBox Series 5 offers a collection of automated 3D scanners for the digitalization of parts ranging from small to 3000 mm.

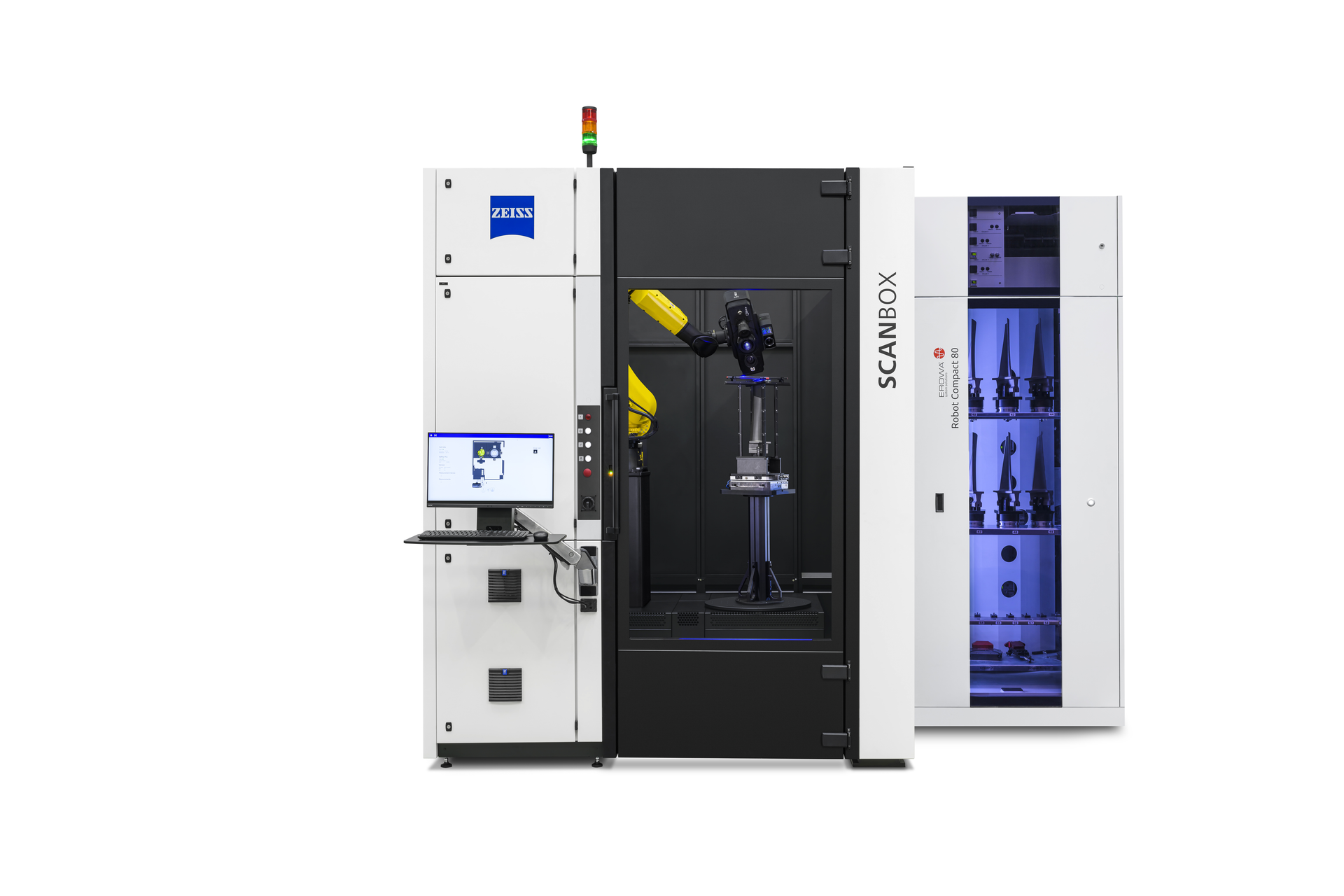

Automated loading and unloading for shorter cycle times.

Combining ATOS ScanBox technology with an EROWA automated part handler and PLC for increased throughput and process reliability, the ATOS ScanBox BPS autonomously digitizes parts for up to 11 hours. Using this intelligent 3D scanning solution saves time by cutting out the need to load and unload parts manually.

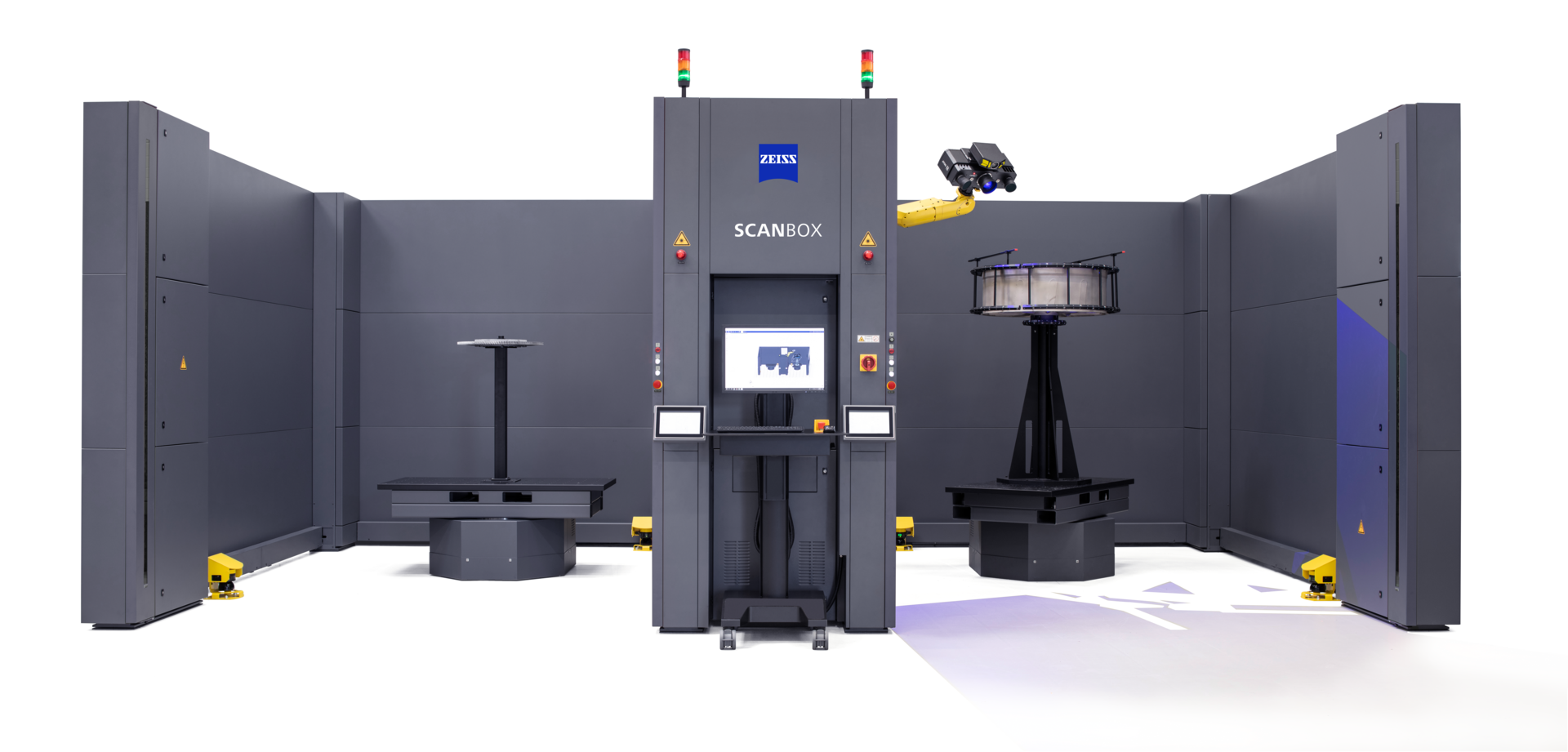

Higher throughput optimizes production.

With advanced robotics and accurate blue light 3D scanners, these shop floor automated 3D metrology solutions are engineered to quickly digitize large and heavy components such as those in the aerospace and automotive industries. Achieve shorter inspection times and less scrap and rework to support lean manufacturing strategies.

Digitalization of large and heavy parts.

Innovative 8-axis kinematics enable flexible sensor positioning, allowing ATOS ScanBox Series 7 to quickly deliver full-field measurement data in the form of an accurate digital twin.

Fast, complete measurement of entire car bodies and attached parts.

With dual automated, accurate 3D scanners mounted on two 8-axis kinematic robotic arms, the ATOS ScanBox Series 8 is an ultra-fast technology capable of digitizing a complete body-in-white in just 30 minutes.