ATOS 5| Industrial Optical Metrology Solution

Game changer in 3D scanning technology with high-speed and high accuracy

Developed for industrial use, the ATOS 5 delivers high-precision data in a short measuring time even under harsh conditions. The full-field 3D measuring data allows comprehensive process and quality control, visualizing hidden errors and thus speeding up production processes. The right combination of hardware and software allows for safe integration of 3D metrology into production. The industrial housing is protected against dust and splash water. The whole system ensures fast and interference-free data transfer.

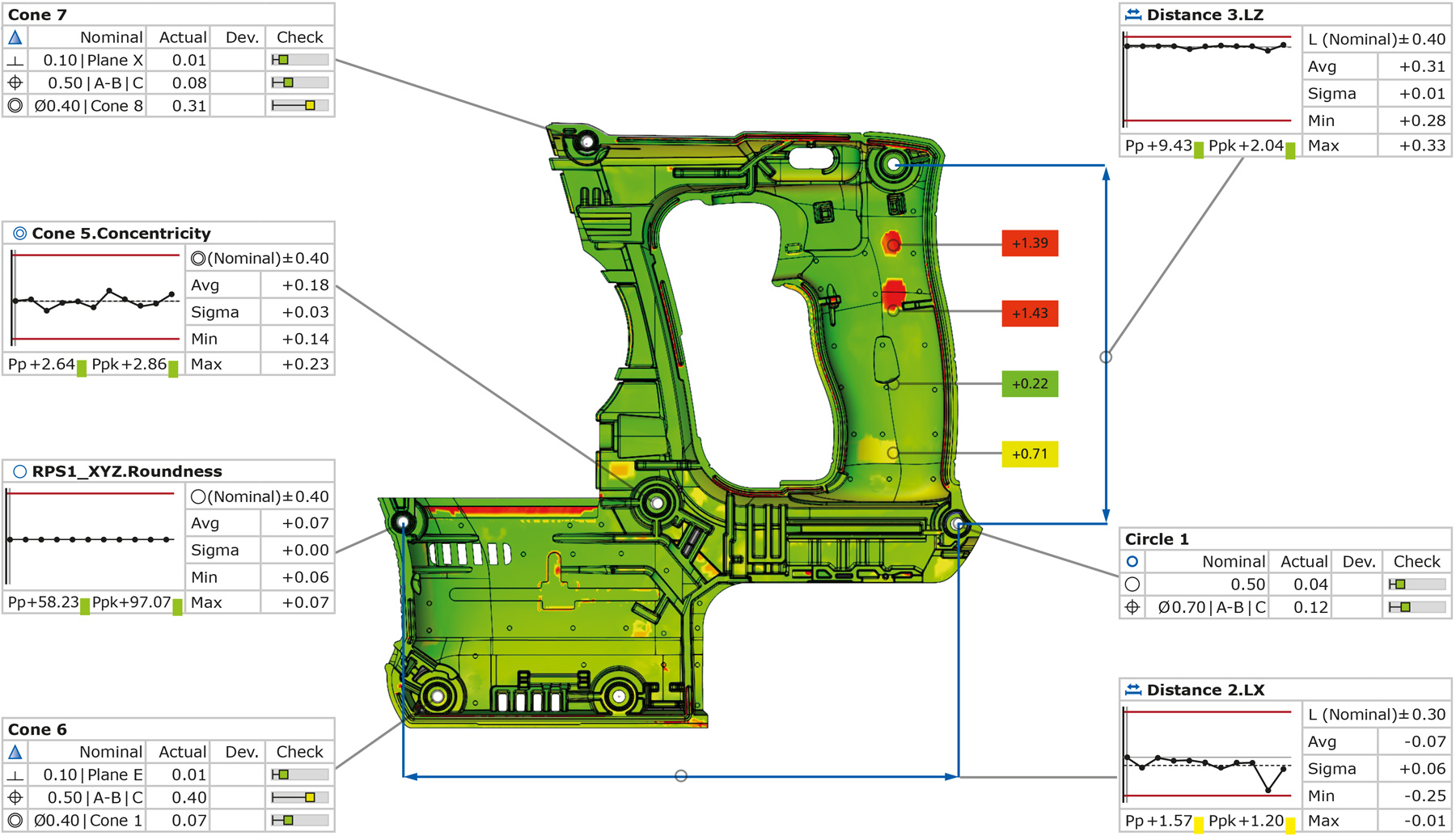

Highest Data Quality

With its powerful light source, ATOS 5 delivers high-precision data for a diverse range of manual and automated applications, from tools and molds to plastic and metal parts. The ZEISS data quality is particularly evident in the detail sharpness of the 3D models, for example, in the precise display of smallest details, rib structures, narrow radii or hemmed edges.

Blue Light EqualizerUniform, non-coherent, speckle-free light |

High-speed 3D scanningMeasurements as fast as 0.2 seconds |

High detail resolutionProjection of very small fringes per unit area |

Bright LED light source1.5 times brighter |

Low noise levelPrecise coverage of complex geometries |

Fast data processingFiber optic cables and robust connectors |

High speedMore light and fast cameras allow for short exposure times on all surfaces. With 0.2 seconds per scan and 100 frames per second, ATOS 5 constitutes a high-speed 3D scanning system providing highest precision. |

Process safetyATOS 5 ensures safe processes through fiber optics and intelligent sensor communication, resulting in a completely self-monitoring system. |

Innovative 3D scanning technology for quality control, reverse engineering, optical tracking, and back projection.

Plastic components |

Casted parts |

Airfoil inspection |

Automotive hang-on parts |

Complete body-in-white car body inspection |