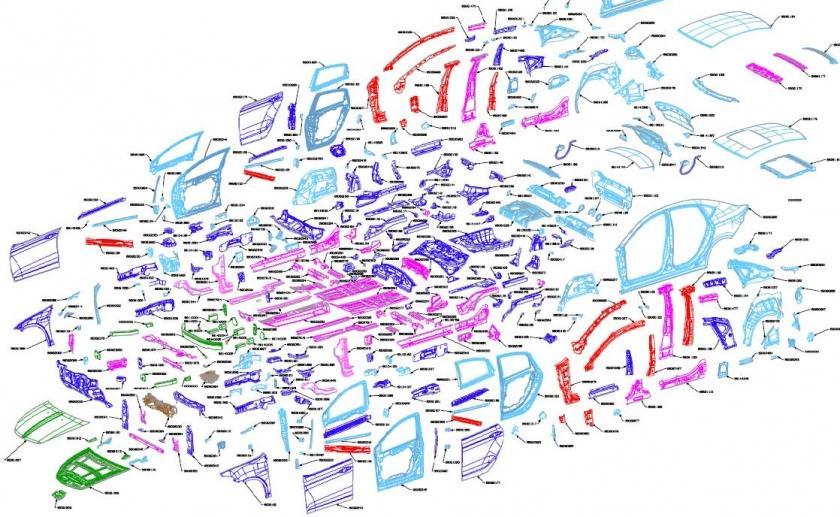

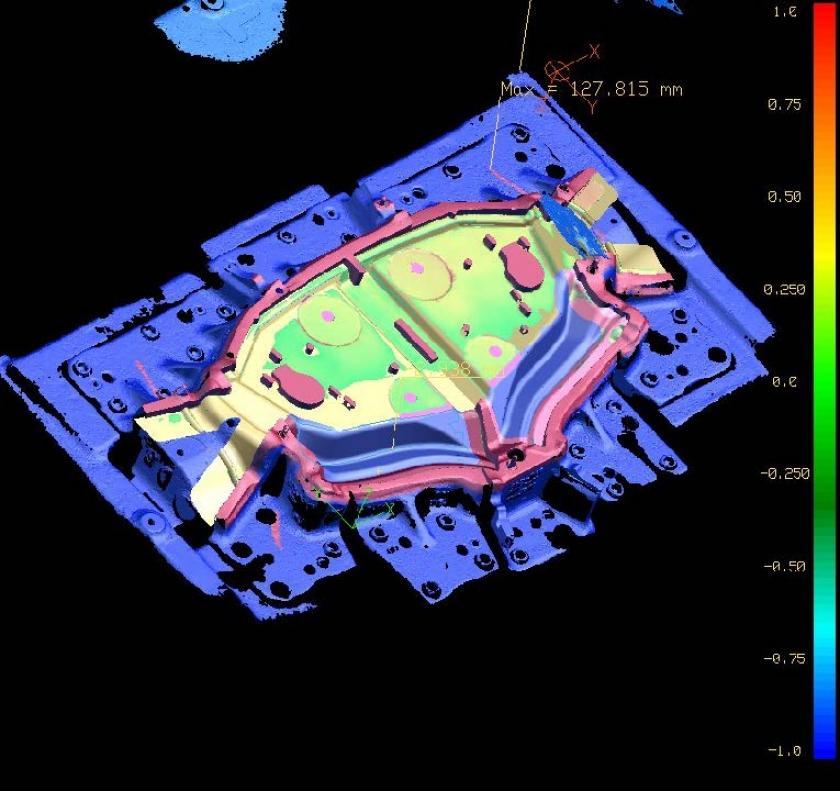

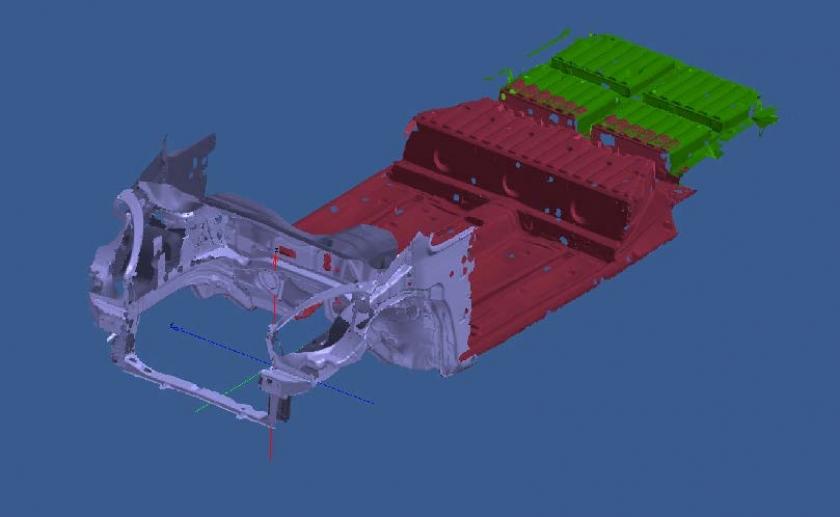

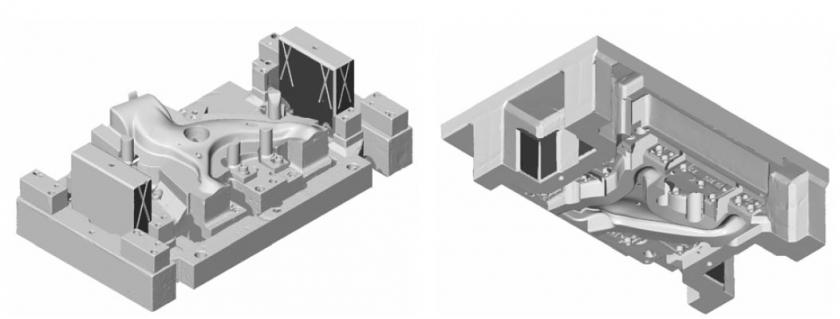

Stamping

Case Studies

Learn how stamping companies are using accurate structured blue light 3D scanners, comprehensive inspection software, photogrammetry technology, and/or automation to improve manufacturing processes with rapid precision measurements