3D Technology Applications

Benefits of High Quality, Accurate, and Fast Metrology Technology

Metrology is more than just finding coordinate values. It’s about quickly delivering accurate results to take the guess work out, so your company can rapidly turnaround the right strategy to save precious time and money. Having the capability to gather high quality and accurate data in rapid speed greatly impacts the downstream processing and applications in a chain reaction manner. That is why 3D metrology plays such a tremendous role in product development, manufacturing, to production. The purpose of measurement is to lead to improvement, and metrology has evolved to conquer these challenges.

Having a robust inspection process to improve quality control is critical in today’s world of manufacturing. With accurate 3D scanning and inspection analysis, companies can reduce iterations/tuning loops and quickly derive the proper corrective action without slowing down their time-to-market goals.

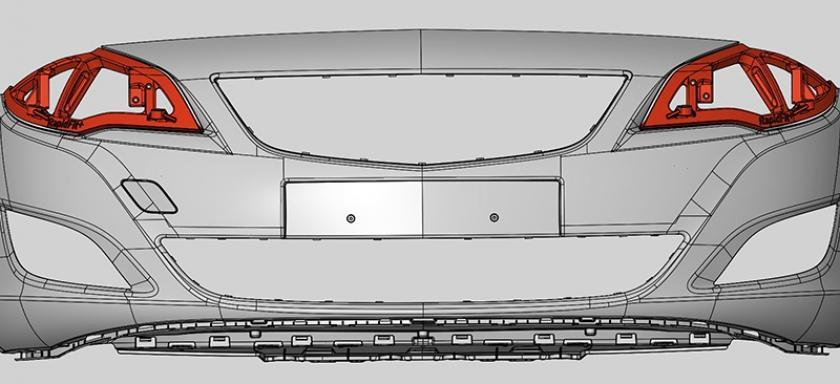

A key contributor in making reverse engineering an easier task is to start with accurate, clean, and high resolution scan data. It helps to utilize a scanning system that will capture your part’s smallest and most complex geometric features.

A high-quality 3D scanner makes 3D printing and rapid prototyping fast and easy. ATOS processes its data with higher point density where critical features exist such as holes, edges, radii, etc... This is a key attribute to downstream data processing because the more a part's features are defined in the scan data, the less manual time is required for creating a solid model.

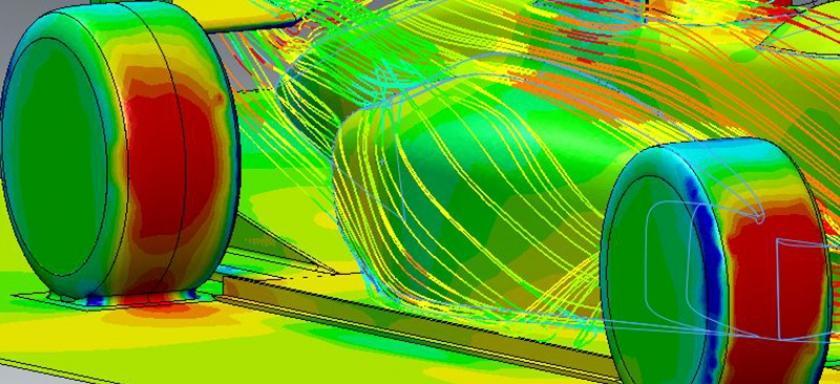

Data from 3D scanners can be utilized for CFD and FEA simulation and analysis. The benefit with ATOS is the accurate scan data and the ability to regularize the mesh which helps CFD/FEA software packages read in the data and measurements.