Hilti

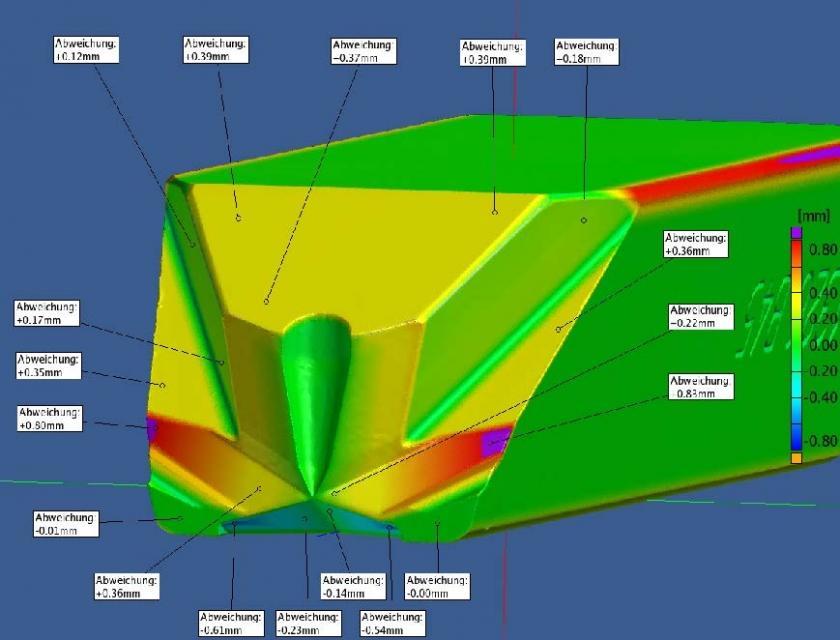

ATOS SO in the Product Development and Quality Control

This presentation from 2006 explains Hilti's objective and goals they have reached by using ATOS for inspection and FEA analysis of their power tools.

This presentation was given at the GOM International Conference in 2006. To receive a copy of the entire presentation, please fill out the form below or email .