Injection Mold & Plastics

Case Studies

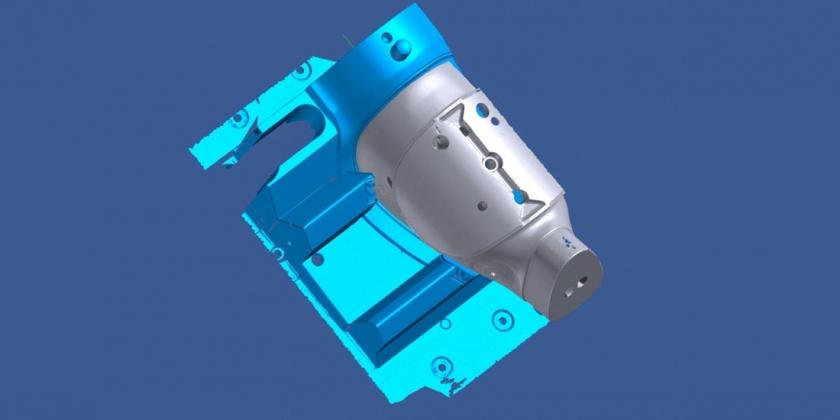

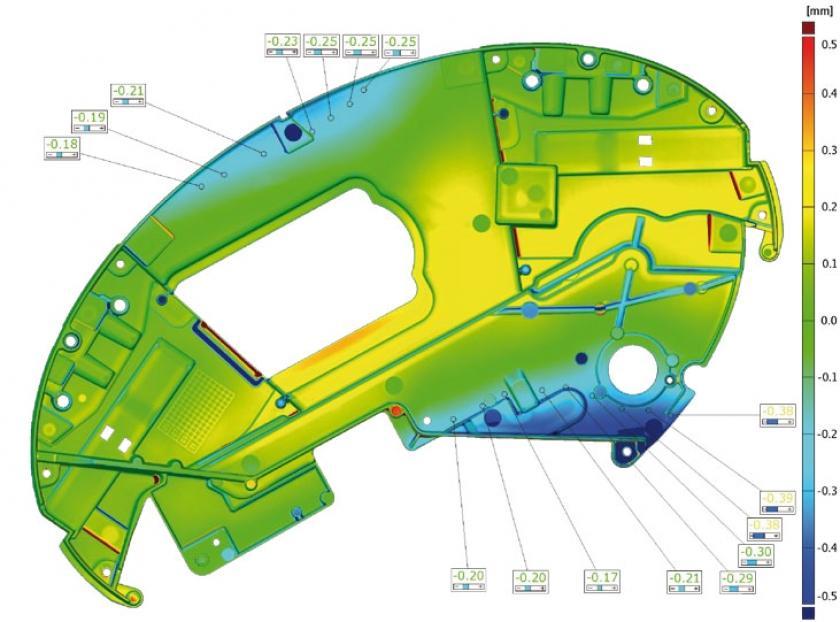

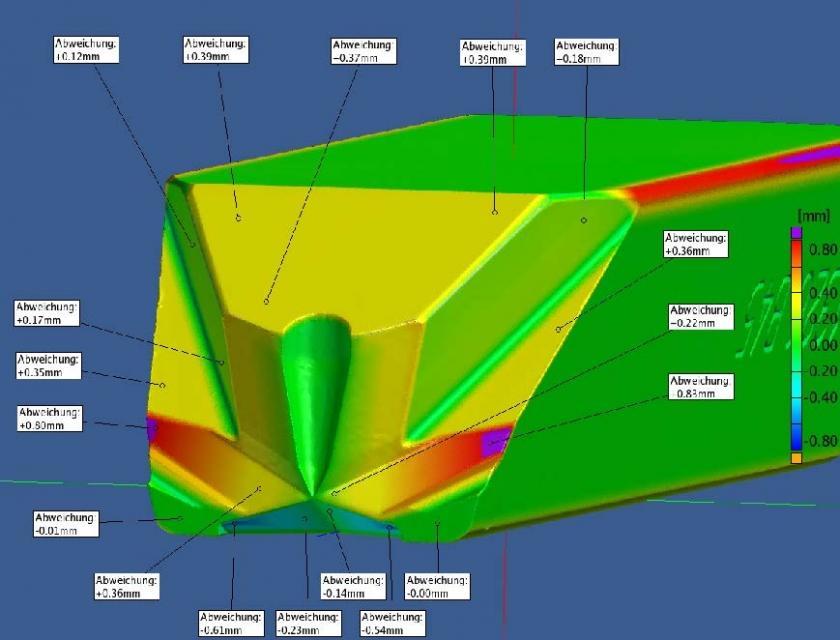

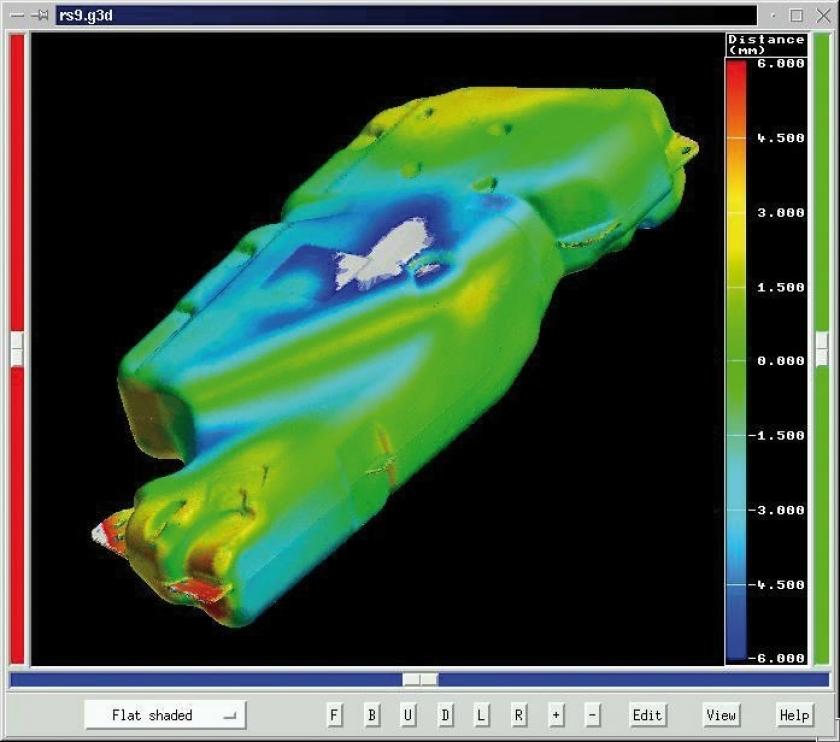

Learn how injection mold and plastic companies are using accurate structured blue light 3D scanners, comprehensive inspection software, photogrammetry technology, and/or automation to improve manufacturing processes with rapid precision measurements