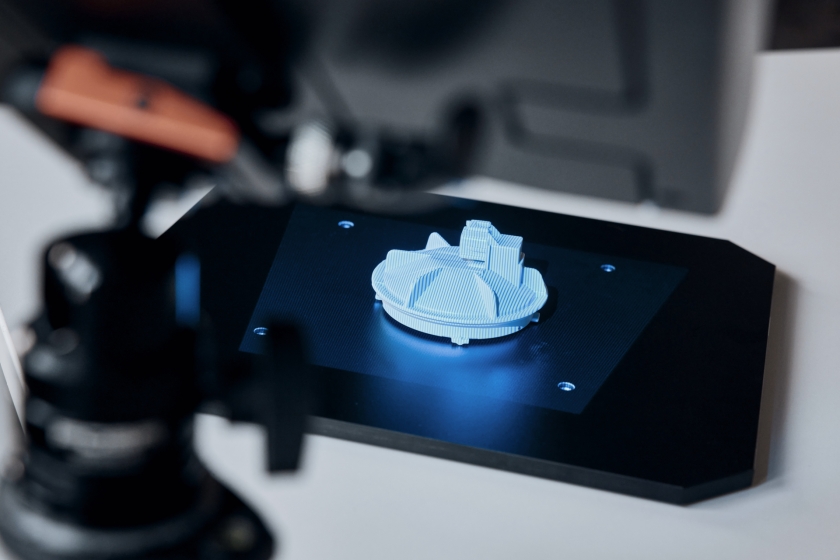

ATOS Q is a compact, metrology-grade blue light 3D scanner. ATOS is an abbreviation for advanced topometric optical sensor, and the Q stands for Quality.…

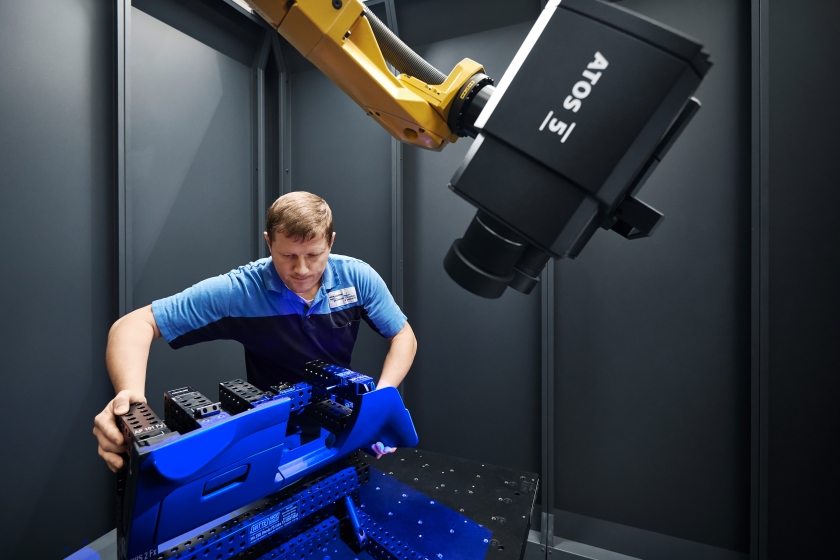

The ScanBox Series 8 is an automated optical 3D measuring machine used to collect full surface geometry and quickly deliver an accurate digital twin. This…

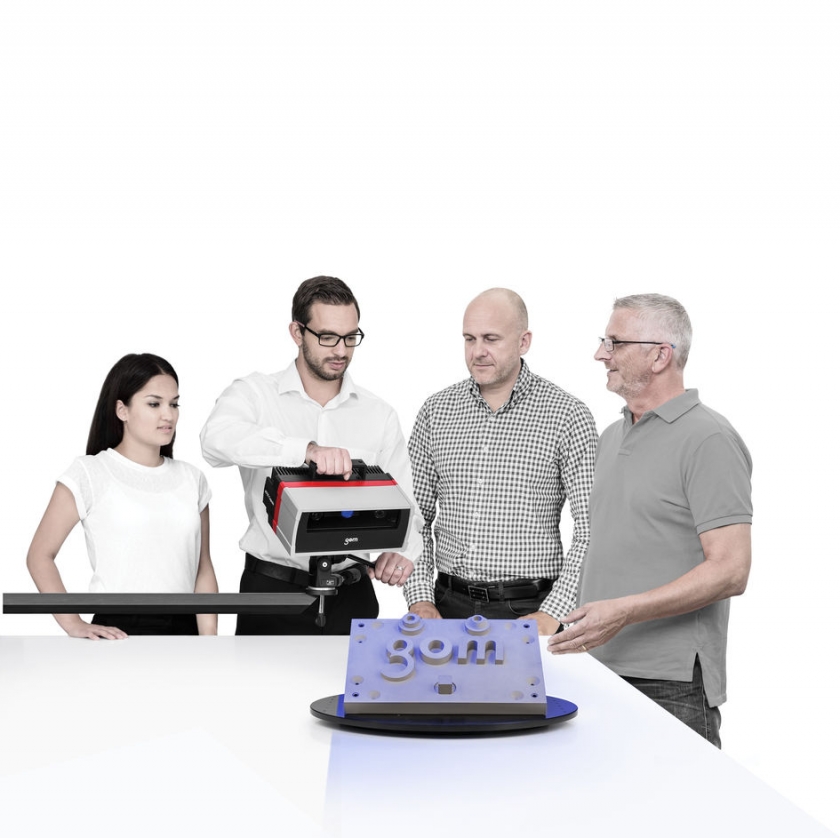

Optical 3D measurement systems are essential for ensuring quality and accuracy across various industries. Optical 3D measurement systems use light-based technologies such as lasers, cameras,…

The challenges and demands of the automotive industry are evolving at speeds as fast as the cars it manufactures. Keeping up with customer satisfaction, performance,…

3D metrology is the scientific study of physical measurement using technologies that can create a full 3D representation of an object's geometrical shape. 3D metrology…

Industrial manufacturing requires high standards of quality, efficiency, and accuracy to ensure the performance of the resulting products. One of the key aspects of industrial…

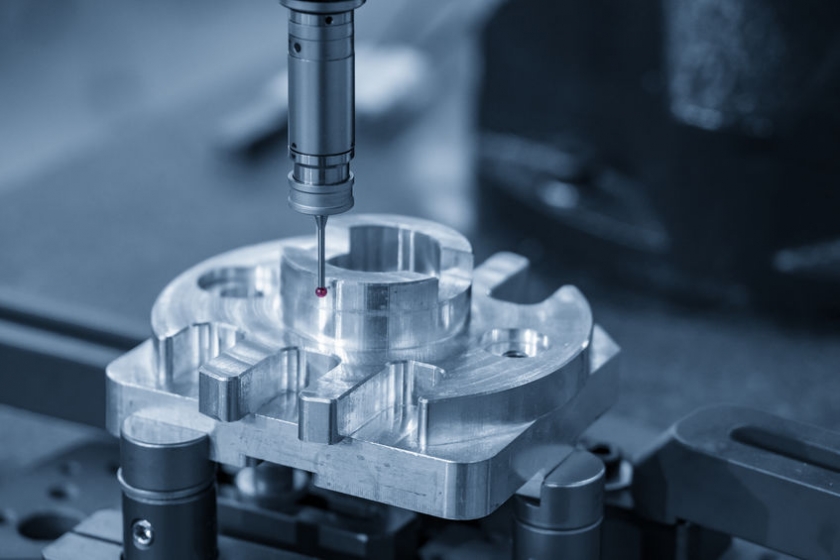

A 3D Coordinate Measuring Machine (CMM) is a precision measurement device that accurately collects XYZ coordinate points from an object's surface to define and analyze…

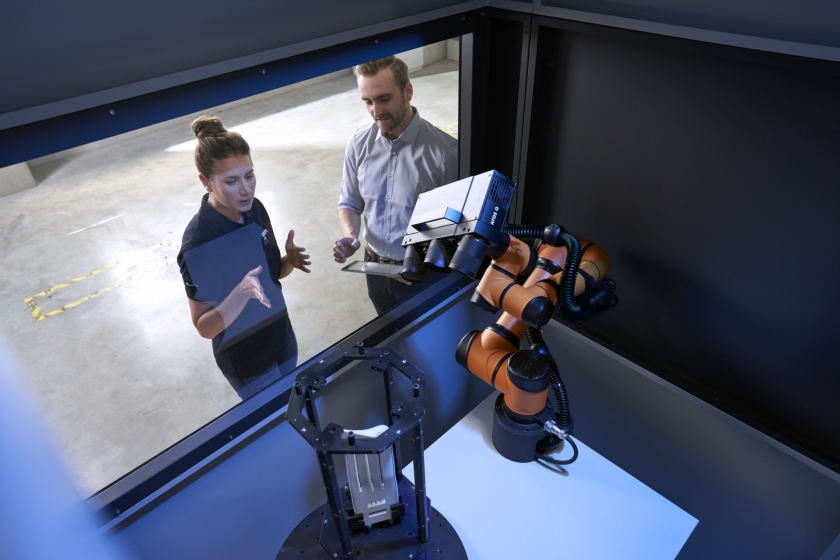

Automated metrology is the use of robotics or other automatically controlled equipment, systems, and software to measure processes, parts, or products repeatably. Launching such equipment…

Digital transformation in manufacturing is constantly evolving. Understanding how to implement it now will help your business in the future. Read on to learn about…

Each new year is an opportunity to improve your processes and products. That often means improving the technology you use within your processes to create…

Manufacturing professionals across the world are anticipating the in-person return of IMTS. Following a four-year absence, IMTS 2022 will be held in Chicago from September…

Every manufacturing process produces variation. The level of variation depends on the production process, the materials, the environment, and the standards for your industry. But…

When choosing a 3D scanner, you can't simply purchase the cheapest option available and expect the results you need. If you want the best 3D…

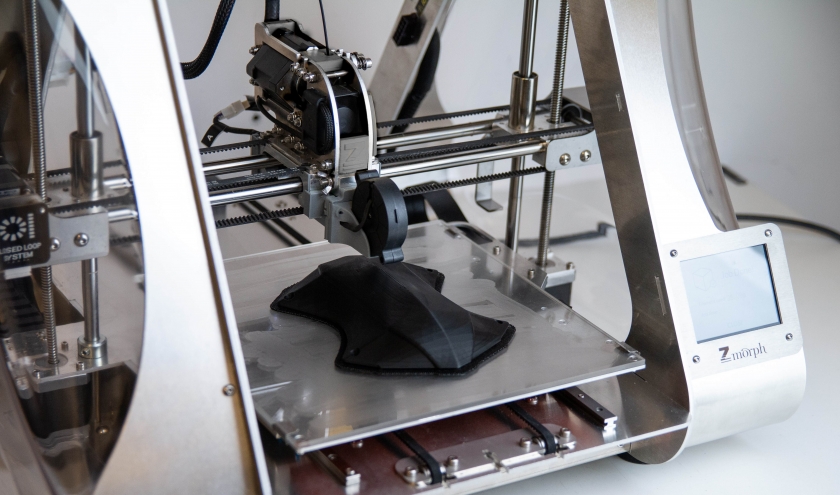

If you have a 3D printer-ready digital model of a part, you can 3D print just about anything. But what if you don't have a…

Many sectors are rapidly adopting automated inspection. Industry-leading companies are making automated inspections the bedrock of their quality systems, increasing standards of conformance, precision and…

Digital transformation is critical in modern manufacturing to produce higher quality products faster at a lower cost. Transitioning out of traditional engineering systems and stepping…

Small components present particular challenges for measurement. Certain aspects of small parts contributing to these challenges include the fine level of detail required, the scale…

Modern metrology technology is changing. With constant rapid technological developments emerging and your own busy schedule to keep up with, it's easy to fall behind…

Quality control ensures your final product adheres to set standards, satisfies customers and prevents failures. However, effective quality control requires systematic improvement from a quality…

Handheld CMM scanners now have more advanced capabilities than when they first emerged on the market, making them a reliable tool for working in industrial…

A Portable Coordinate Measuring Machine (PCMM) is a reliable solution that's easy to use and quick to set up. You can use a hand-held portable…

Smart manufacturing trends in 2022 focus on improving efficiency to reduce production costs while also developing better products. Tapping into these strategies requires the continuous…

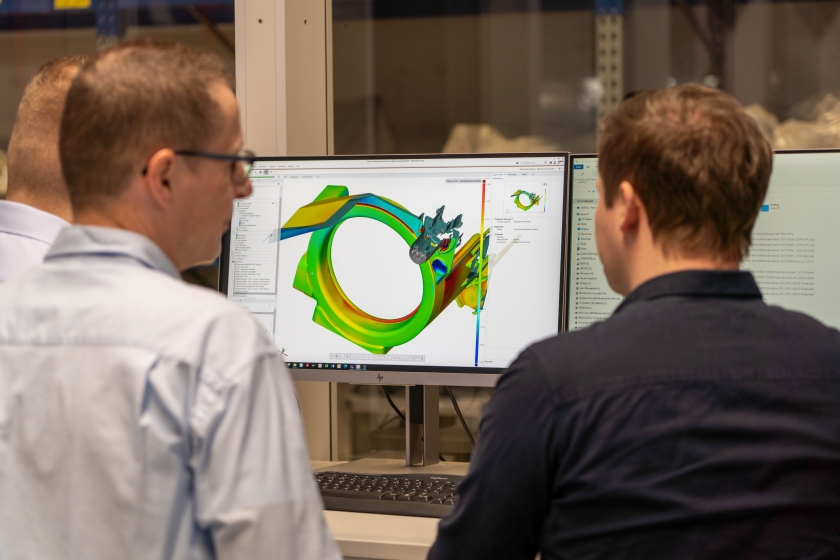

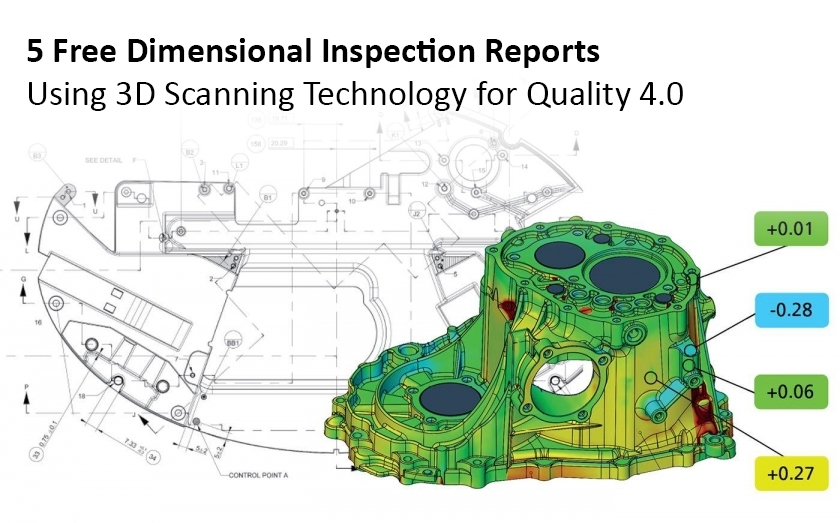

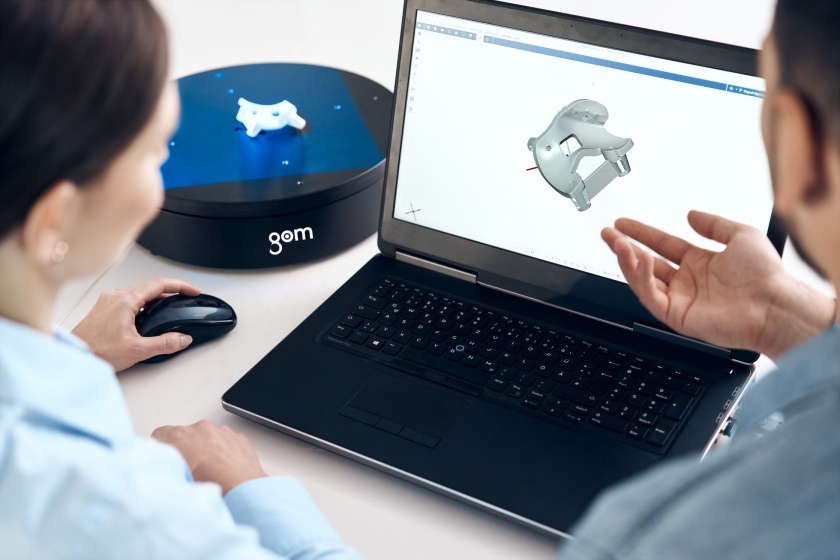

Capture 3D's ATOS technology enables 3D inspection analysis, an extremely powerful tool for digital engineering. It is important to understand the inspection basics for comparing…

Capture 3D's GOM Software contains many features to help increase your efficiency. One of these is the ability to use, manage and customize skins that can…

As 3D scanning technology continues to develop rapidly, many types of 3D scanners are emerging to fulfill different needs. The good news is, there is…

Many digital engineering strategies that enable the future of product development, manufacturing, quality control, and production begin with 3D scanning. 3D scanners work with advanced…

Capture 3D's GOM Software contains many features that help you advance your digital engineering capabilities. The GOM Software function known as back projection provides many benefits,…

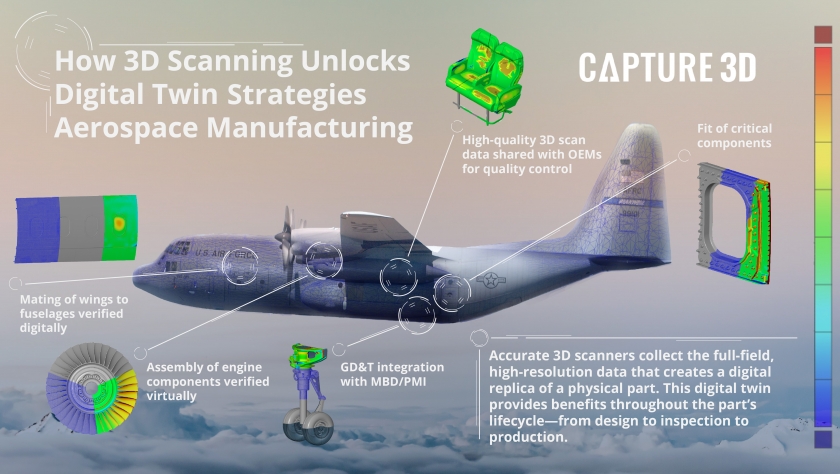

More than a decade into the Industry 4.0 revolution, you've probably heard a lot about the digital twin concept and how this digital replica of…

Capture 3D's GOM Software contains the unique feature known as image mapping, which allows you to visualize color on your ATOS 3D mesh. This function…

Capture 3D's GOM Software provides access to GD&T functions that serve as a powerful inspection tool. Requiring only seconds to implement in this digital setting,…

Capture 3D's GOM Software is a powerful 3D measurement data inspection tool that can automate and simplify your inspection process by using CAD and a CAD…

Capture 3D's GOM Software is an effective tool for analyzing 3D measurement data. Understanding the shortcuts and hotkeys available in GOM Software is essential to utilize…

Capture 3D's GOM Software is a powerful digital tool used in manufacturing to efficiently analyze and inspect measurement data from 3D scanners, laser scanners, handheld…

Coordinate Measuring Machines (CMMs) have long been the gold standard. As a first-generation technology, traditional CMMs have led to modern CMMs by exposing strengths and…

Capture 3D's GOM Software increases inspection efficiency with user-friendly workflows that make it easier and faster to analyze various elements. Within a few clicks, you can…

Throughout modern manufacturing history, CMM programmers have been relied upon for a lot. To maintain timeliness and continue to execute a myriad of responsibilities at…

Have you ever run into issues with your quality engineering process? Are you spending too much time trying to figure out what the corrective action…

Capture 3D's GOM Software is packed with shortcuts to increase inspection efficiency by simplifying the functions you use the most. The I-Inspect wheel, or I-Inspect…

Capture 3D's GOM Software offers many solutions to help advance your digital engineering skills with just a few clicks. The golden mesh, or average mesh,…

Capture 3D's TRITOP photogrammetry system is extremely compact and portable, making it easy to measure larger objects by simply walking around the subject and taking…

GOM Inspect software contains features engineered specifically to help aerospace and power generation manufacturers address the specialized drawing callouts associated with airfoils. GOM's airfoil inspection…

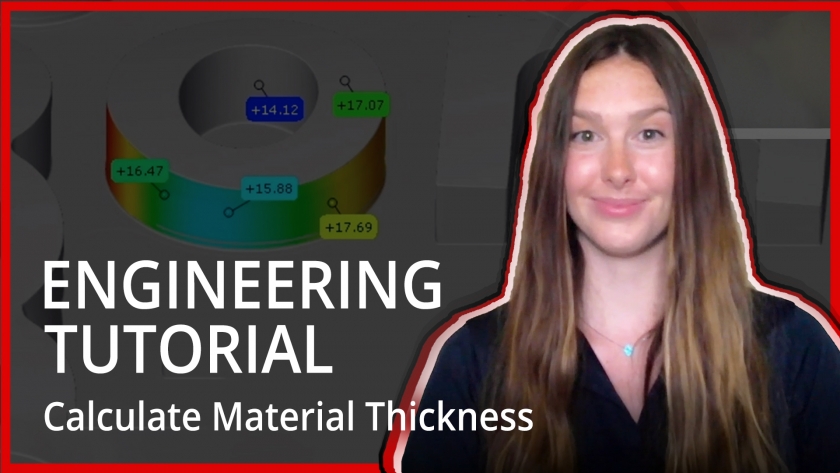

Free GOM Inspect software 2019 completes essential engineering calculations with just a few clicks. The software's functions are designed to simplify common and repetitious processes for significant…

Join us as we go back to the future to digitize our CEO Rick's 1976 Ford Bronco and demonstrate the innovative TRITOP Photogrammetry and ATOS…

Imagine you must pay $100,000 for a very complex fixture to clamp your part into place. Now, imagine you don't have to pay $100,000 to…

In manufacturing, having multiple stages requiring the same features to be inspected is quite common— but it doesn't have to be. Check out this tutorial…

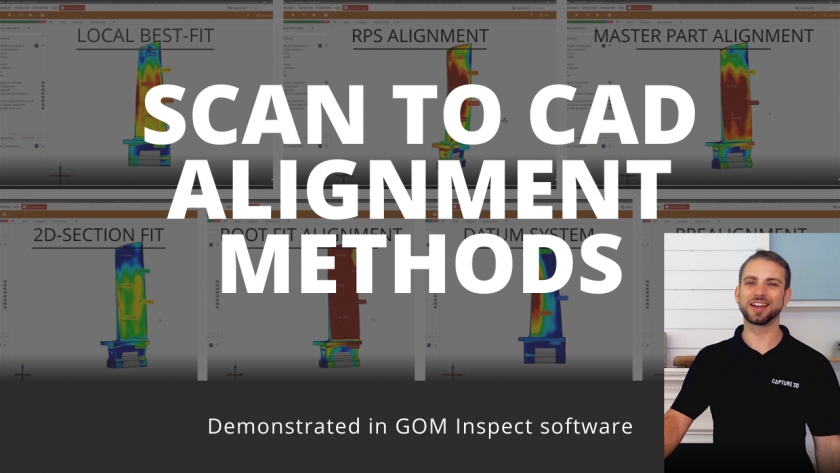

The free GOM Inspect Software 2019 is designed to make every step of the measurement process simple and efficient, including technical processes like CAD part alignment. Since GOM Inspect caters…

The combination of smart technology and automation is central to this integration, helping manufacturing organizations reach new levels of productivity through the Internet of Things (IoT), or, in the case of manufacturing,…

While Capture 3D is a designated essential business, we have taken measures to ensure the highest level of support, service, and safety to our customers.…

Have you ever wondered how a CMM machine works? Or how it differs from a 3D scanner? At first look, they both collect accurate measurement…

Technology is modernizing how businesses operate, especially on the production floor. We're entering an era known as "Industry 4.0," a revolution lead by the exciting growth of…

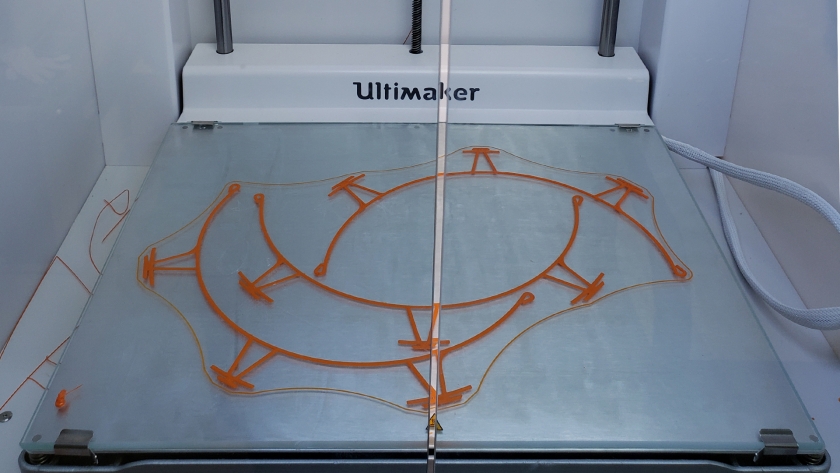

Even during this pandemic, humans come together alongside technology to share ideas and help others. As the supply of Personal Protective Equipment (PPE) quickly depletes…

Manufacturing has been the backbone of the United States throughout history, fueling its job market, stimulating economic growth, and supporting innovation that results in products…

3D scanning is the process of collecting data from the surface of a physical object which accurately describes the shape in terms of three-dimensional space.…

3D scanning is changing the landscape of a number of modern industries. Manufacturing, construction, aviation, aerospace, oil refineries, and a number of other verticals have…

Handheld 3D scanners are portable devices much the same as ATOS blue light non-mobile scanners that conduct scans quickly and use optical non-contact technology to…

3D scanners are an incredible way to get the most accurate images when you need precision and detail in whatever it is you may be…

Blue light 3D scanners make 3D printing and prototyping more efficient and helps streamline workflows. Using blue light technology, a narrow band of LED blue…

If you're in the market for a blue light 3D scanner, you probably already know that they reduce costs and improve reverse engineering and inspection processes; however,…

In manufacturing, reverse engineering enables the production or reproduction of physical objects using the physical object itself as the guide. This process is only possible…

3D scanning Quality is one of the most important aspects of manufacturing today. Businesses must be able to trust that the systems they use will do…

Computer Aided-Design (CAD) and reverse engineering play a major role in manufacturing, quality, analysis, and research. As industries move towards more advanced, automated, and scalable processes…

The accuracy of measurements can make or break a business delivering physical goods to market or an organization performing critical research. For this reason, it…

3D scanning is an important part of quality assurance, prototyping, manufacturing, and reverse engineering. The precise 3D blueprints and rapid workflows enabled by light-based non-contact…

With the explosion of 3D printing reaching users ranging from worldwide manufacturing organizations to families looking for an innovative way to encourage creativity, it’s no…

3D scanning is a technology that is changing manufacturing and engineering processes in every industry. The 3D scanning market is projected to reach $5.9 billion…

Optical metrology, including structured light scanners like ATOS, is quickly revolutionizing the manufacturing industry. Many of the leading companies in the aerospace and automotive industries…