ZEISS Quality Suite

Your Ecosystem for Modern Metrology Software and More

The ZEISS Quality Suite is a software ecosystem that unites the high-tech 3D software solutions ZEISS provides into one platform. Quickly access any software variant you need— from ZEISS INSPECT to ZEISS INSPECT Airfoil and beyond. You can also easily access the ZEISS Quality Training Center, news, events, and information to keep you up-to-date on the latest in advanced 3D metrology technology.

Tailored to Your Needs for an Optimized Workflow

| |

|

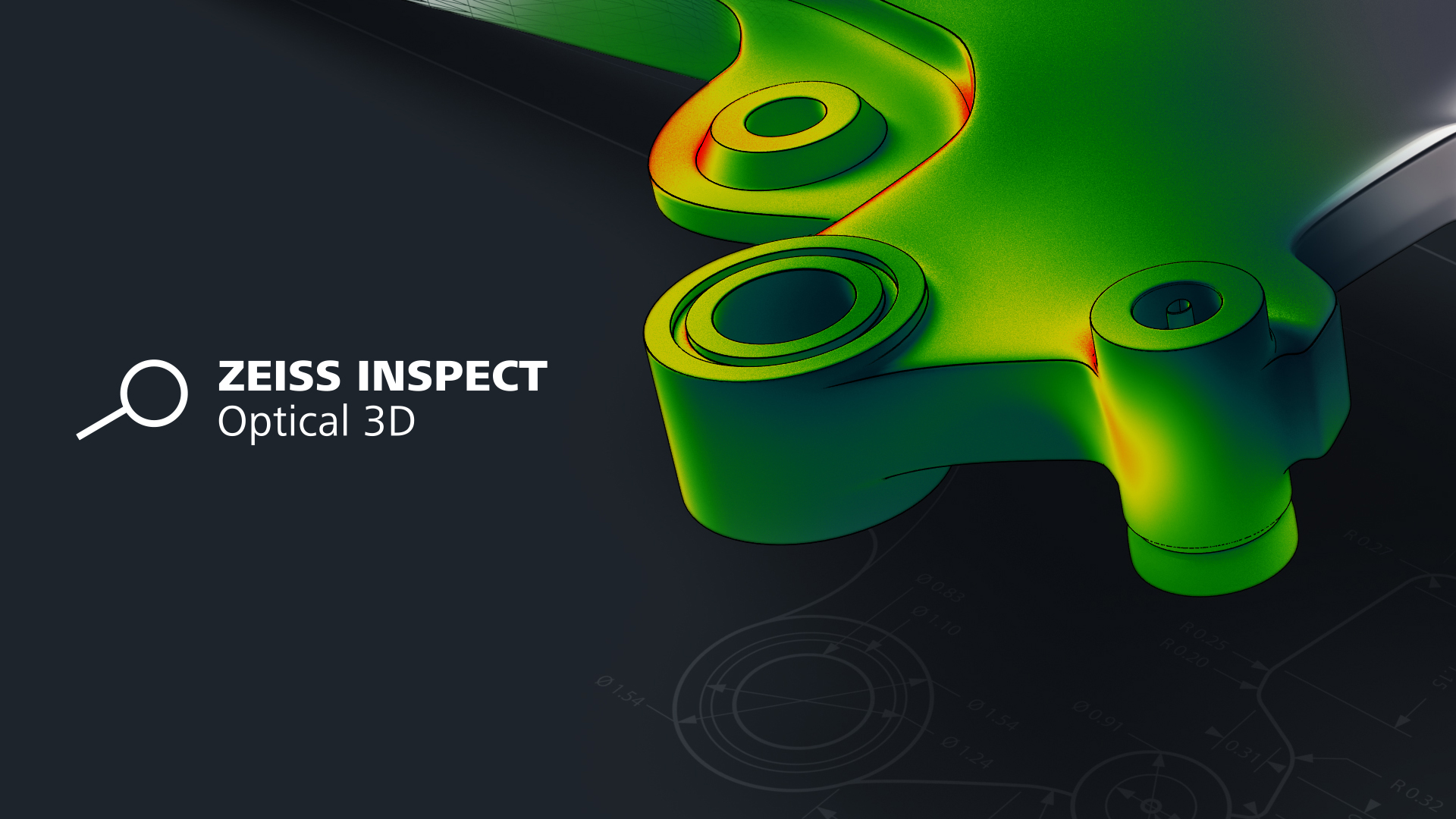

ZEISS INSPECT

Simplify your entire inspection process so you can work smarter, not harder. ZEISS INSPECT is the industry standard for 3D inspection and analysis. Offering extensive GD&T analysis options, a simple nominal-actual comparison and the ability to automate your software with an active parametric concept, ZEISS INSPECT also allows you to further customize your software with Python API.

Free ZEISS INSPECT: Data from 3D scanners, laser scanners, CT scanners, CMMs and other sources can be imported and polygonized.

|

|

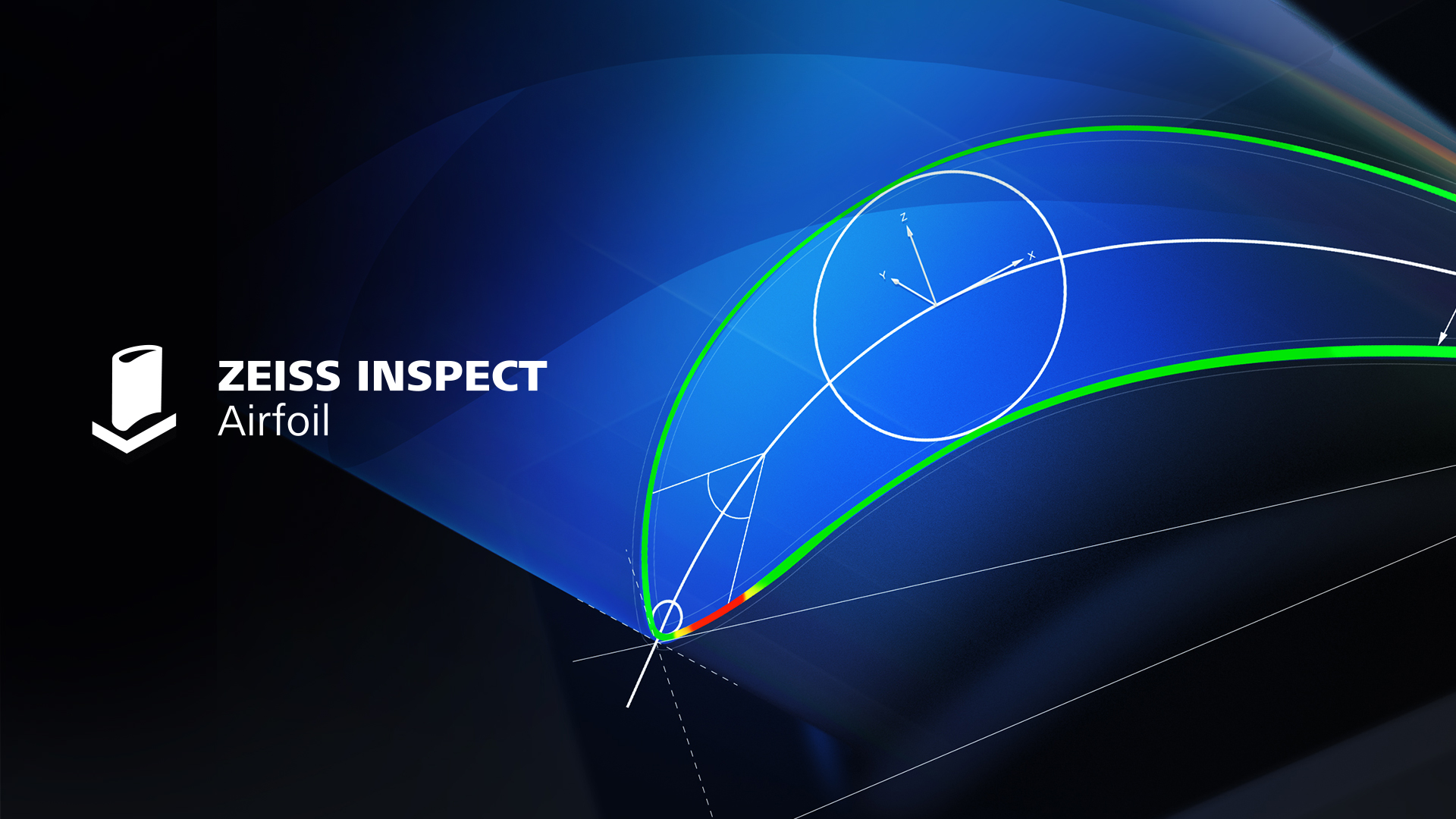

ZEISS INSPECT Airfoil

ZEISS INSPECT Airfoil is engineered to support the metrological analyses of blades and airfoils. With features designed specifically for measuring and inspecting various aircraft and gas turbine parts, including wing products, turbine blades and guide vanes, this software allows you to create industry-specific 2D profile inspections quickly and easily. The user-friendly inspection steps range from profile stacking point to profile form and position inspection using a non-uniform tolerance band. The automatic surface deviation computation enables visual inspections. Identify production residue, wear and tear, and surface defects and even use the data for adaptive machining.

|

|

ZEISS Reverse Engineering

With ZEISS Reverse Engineering software, you can scan a part in ZEISS INSPECT or other quality control software for manufacturing and import the STL or PLY data and ASCII formats into ZEISS Reverse Engineering software. This intuitive manufacturing quality software guides you through a few simple steps, generating a highly accurate CAD model. ZEISS Reverse Engineering software also supports tool correction.

|

|

ZEISS INSPECT X-Ray

Quickly and accurately analyze internal and external geometries, defects, structures and the assembly of your entire part. No matter which computed tomography system (CT) you use for measurement, ZEISS INSPECT X-Ray is the industry standard for inspecting CT data. This quality control software for manufacturing is system-independent, allowing you to import your CT data in all standard formats directly.

|

|

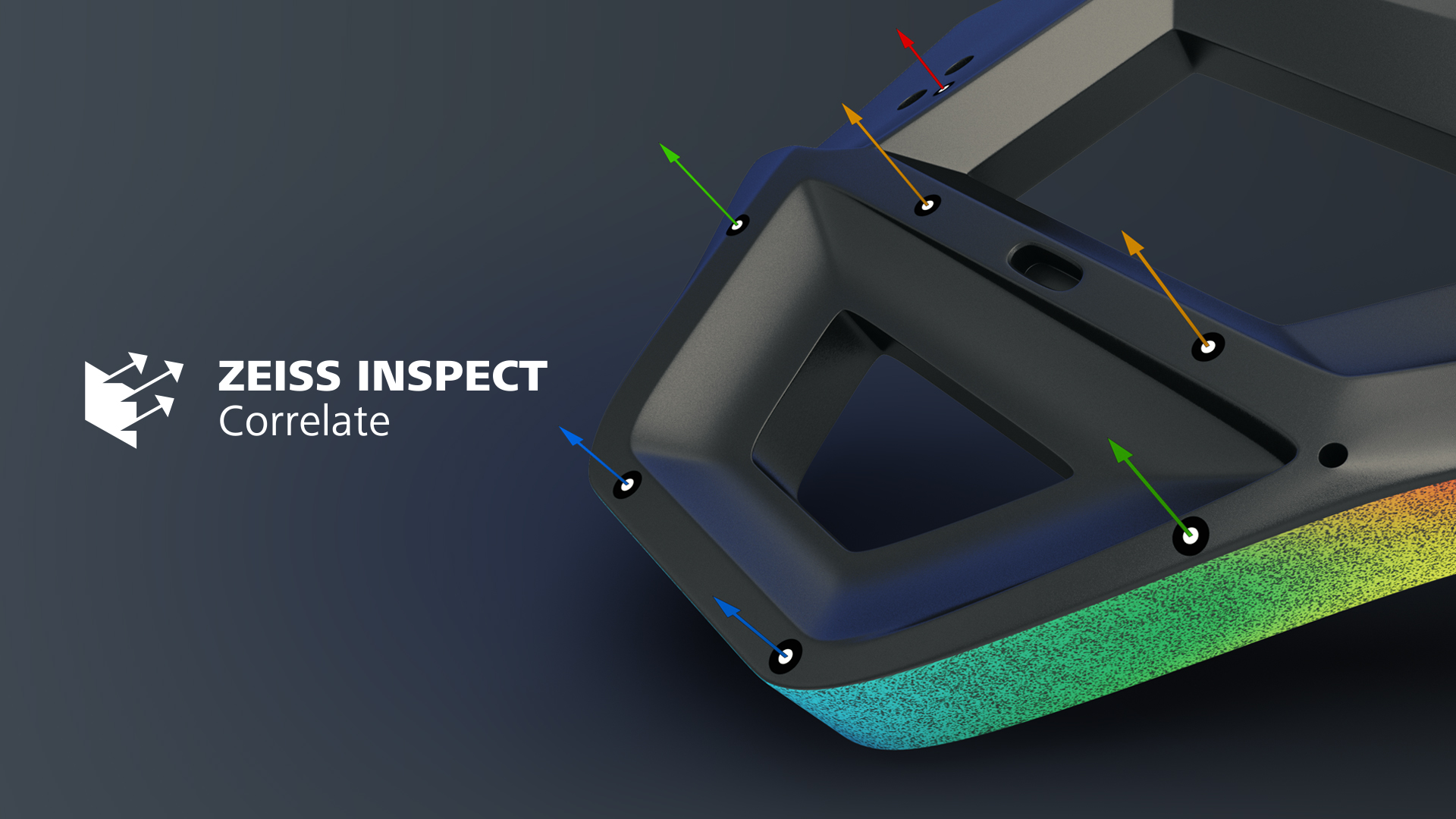

ZEISS INSPECT Correlate

ZEISS INSPECT Correlate is an inspection software for strains, 3D displacements, 3D deformations, velocities and accelerations, as tested in many production-related research and developmental tasks. This quality control software evaluates 2D or 3D data based on digital image correlation.

|

|

ZEISS Quality Training Center

Get the most out of your quality control software experience. With live online training and flexible e-Learning courses, the ZEISS Quality Training Center is curated to teach you how to use your manufacturing quality software optimally. Participate in training courses and track your progress in your personal account.

|

|

Languages

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| English |

Chinese |

French |

German |

Italian |

Japanese |

Portuguese |

Spanish |