3D Scanning For Reverse Engineering:

Everything You Need To Know

In manufacturing, reverse engineering enables the production or reproduction of physical objects using the physical object itself as the guide. This process is only possible with an accurate 3D scanner to collect data from the object's surface. That data defines the geometric identity of the object containing specifications that create a model for producing the object. 3D scanning enables developers, manufacturers, and engineers to produce accurate digital twins of physical parts. While this ability makes reverse engineering faster and easier, not every 3D scanning solution is ideal for every reverse engineering project.

Accurate 3D scanners enable reverse engineering, allowing engineers to leverage accurate 3D measurement data to reproduce objects as they were first manufactured. With high-resolution data and intelligent metrology software, manufacturers can take their reverse engineering projects a step further by using the resulting scan data to simulate and evaluate modifications and improvements to the object before physically producing it.

With the rapidly developing 3D scanning industry, there are more options for a reverse engineering scanner than ever. Still, it can be challenging to know which one is the best 3D scanner for your reverse engineering project. For example, 3D hand scanners have become a popular choice for their affordability and compact size. However, depending on certain specifications of your project, a different 3D scanning solution may be a better choice.

We've compiled a list of everything you need to know about accurate 3D scanners that support fast and efficient reverse engineering for manufacturing.

Reverse Engineering Quality Data, Quality Products

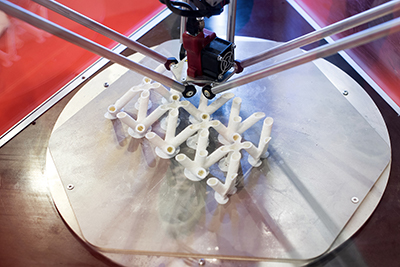

The purpose of reverse engineering is to recreate a physical part or object without beginning with a digital file or computer-aided design (CAD) model. Instead, an accurate 3D scanner is used to collect data from the surface of the physical part, which produces an STL file that becomes the digital twin of the part. With this data, the part can be reproduced, improved or archived.

The best 3D scanner for reverse engineering is typically a non-contact blue light 3D scanning solution due to its speed, precision and ease of use.

Producing any part or product requires a model to begin with, but when you're reverse engineering a product, the model is generated from the object. For the reverse engineering process to be successful, the data the makes up the model must be precise and high-resolution.

Quality data is essential to reverse engineering because you'll rely on the data as your guide for reproducing the part or object. Noisy or junky data could slow down your reverse engineering process because of its inability to create a model that includes complex geometric shapes. You'll end up spending unnecessary time scanning parts again in hopes of collecting adequate data to move forward with the reverse engineering process.

To ensure that you have the best 3D scanner for reverse engineering, consider for what exactly you'll use your 3D scanner.

Using a Handheld 3D Scanner on the Production Floor

Automated 3D scanners are the ideal metrology solution for the production floor because the 3D scanner is attached to a mechanical arm that slowly and steadily gathers accurate 3D measurement data from the object's surface. Automated 3D scanners help accelerate 3D measurement processes and accomplish repetitive measurements quickly. However, on the production floor, a handheld 3D scanner may slow you down because you must collect the data yourself and make sure that you get a scan from every required angle. While handheld 3D scanners are accurate solutions, they can slow down processes on the production floor. Automated 3D scanners collect data quickly and reliably, making them the ideal choice for 3D scanning for reverse engineering on the production floor.

Implementing the best 3D scanning solution allows manufacturers and engineers to save on labor and production costs because fewer iterations are needed to produce a quality product. With fewer employees tied up performing repetitive tasks, they can focus more time on other parts of their workflow.

Blue light 3D scanners are the most popular choice on the production floor because they collect extremely high-resolution 3D measurement data. With millions of accurate data points captured in each quick scan, manufacturers achieve full-field data acquisition in minutes.

Even though 3D hand scanners have the same hardware and software as their non-mobile counterparts, they lack the speed needed to accomplish high throughput on the production floor. However, an accurate 3D hand scanner is sufficient for scanning small objects or obtaining quick measurements for reverse engineering.

For reverse engineering, either a blue light 3D scanner or a handheld 3D scanner can produce accurate data— it's important to choose the best 3D scanner for your specific needs.

Optimizing Your Reverse Engineering Workflow

When choosing a 3D scanner for reverse engineering, it's essential to consider the size of your project. Some 3D scanning methods are more effective for capturing data from large objects, while a handheld scanner will suffice for smaller objects. For example, imagine the size of a small jet, and now imagine scanning that by hand. A more efficient way to capture a digital twin of an object the size of a jet is by combining ATOS 3D scanning technology with TRITOP photogrammetry.

Another primary consideration when choosing the best 3D scanner for reverse engineering is time. Handheld 3D scanners have similar hardware and software that collect quality data, but the person holding the scanner must remain still and maintain the same distance from the object during data acquisition; therefore, handheld 3D scanners aren't a practical metrology solution for every type of reverse engineering project. While it may save money to invest in a handheld scanner, if your project is very large, it will cost you time.

Rather than being attached to a mechanical arm that moves over an object to collect data points, a human operates a handheld 3D scanner. The person using the scanner stands at a distance from the object and scans it from the same distance all around. Handheld 3D scanners accurately collect data from very small to very large objects but require much more time to scan a large item in its entirety. It's only natural for human arms to become tired after a certain amount of time, so for large reverse engineering projects, using another 3D metrology solution is necessary.

In reverse engineering, having precise, clear data provides a better vision of the object. With better data quality, inspecting and analyzing the digital twin of the object for manufacturing and production is easier. If the data you collect is noisy, you'll get stuck performing multiple iterations. If you need to focus on speed, automated 3D scanners will accelerate the data collection process while also removing human error. However, for small objects, an accurate handheld 3D scanner is a suitable option.

ATOS blue light 3D scanners are the best reverse engineering scanners. With speed, high accuracy and reliability, ATOS 3D scanners complete measurement of large objects quickly. When combined with automation, ATOS 3D scanners become a powerful solution that excels on the production floor.

It's best to use an ATOS solution to optimize the workflow of scanning and inspecting large objects such as engines or wings for reverse engineering. Using an accurate handheld 3D scanner for smaller objects is excellent because it can gather and store the large amounts of data necessary for reverse engineering.

Automated 3D scanning speeds up the production process, allowing manufacturers to optimize production workflow by allowing them to walk away during scanning. Since handheld 3D scanners require a person to hold the scanner and walk around the object, it isn't the best metrology solution if you can't be present during the entire measurement process.

Blue light 3D scanning technology allows manufacturers to meet accurate shape and tight tolerance requirements because of their ability to capture intricate details. It's essential to capture every minuscule detail down to the millimeter for successful reverse engineering— and ATOS does this with ease.

In just seconds, you can capture the complete image of the product you are analyzing and copy it for CAD model creation.

To enhance your understanding of a product and further adapt it to meet the needs of your company and customer demands, you'll need quick, efficient and reliable technology. You can remove the stress of scanning multiple times to fix mistakes by investing in an automated metrology solution. You'll optimize production time and be able to rely on precise measurement data.

Since data creates the models you'll use in production, you need accurate data. You can be confident that high-resolution data results in well-designed models and quality products when you use the best 3D scanner.

The right 3D scanner should eliminate workflow strain and enhance the final results. You'll notice quicker manufacturing processes with more reliable outcomes, and your customers are going to notice too.

Reverse engineering with blue light 3D scanners is a crucial way to get ahead of your competition.

What better way to do that than by having the strongest 3D scanner that rapidly collects accurate data? These high-quality 3D scanners are worth the investment and quickly pay for themselves.

Want to learn more? Contact us!

ATOS blue light 3D scanners are the secret to fast, accurate and efficient reverse engineering. No matter the application, having access to accurate data makes the reverse engineering process a lot easier. If your main priority is to save time and money without compromising product quality, ATOS 3D scanners are for you.

If this article didn't answer all of your questions, or you're still deciding between products because you aren't sure which best suits your needs, contact a Capture 3D team member today! We'd love to hear from you and help you choose the best 3D scanner.