What is Modern Metrology Technology?

From the pandemic forcing us to shift the way we work to supply chain issues causing production delays, manufacturers have had to change to keep up with challenging times. Modern metrology technology is also changing out of necessity and out of innovation. With constant rapid technological developments emerging and your own busy schedule to keep up with, it's easy to fall behind with what is new in metrology.

But don't worry because today, we'll help you get back on track by sharing some recent updates and developments from the metrology industry.

What are the Latest Advancements for Metrology in Manufacturing?

Under the influence of Industry 4.0 and the pressure of the pandemic, metrology went through several changes in the last couple of years.

Some of the latest developments include:

Intelligent 3D metrology software

3D metrology software solutions use data collected by a 3D measurement solution, such as a 3D scanner, CMM, or laser tracker, to perform dimensional analysis on a digitized object.

The advanced features new 3D metrology software solutions provide allow users to create digital models and perform many types of analyses.

Common features include:

● Real-time inspection: You can inspect a part on the spot to take necessary corrective measures promptly.

● Polygon mesh: Data from an accurate 3D scanner generates a high-quality 3D mesh of physical products in the form of accurate digital twins that support efficient reverse engineering.

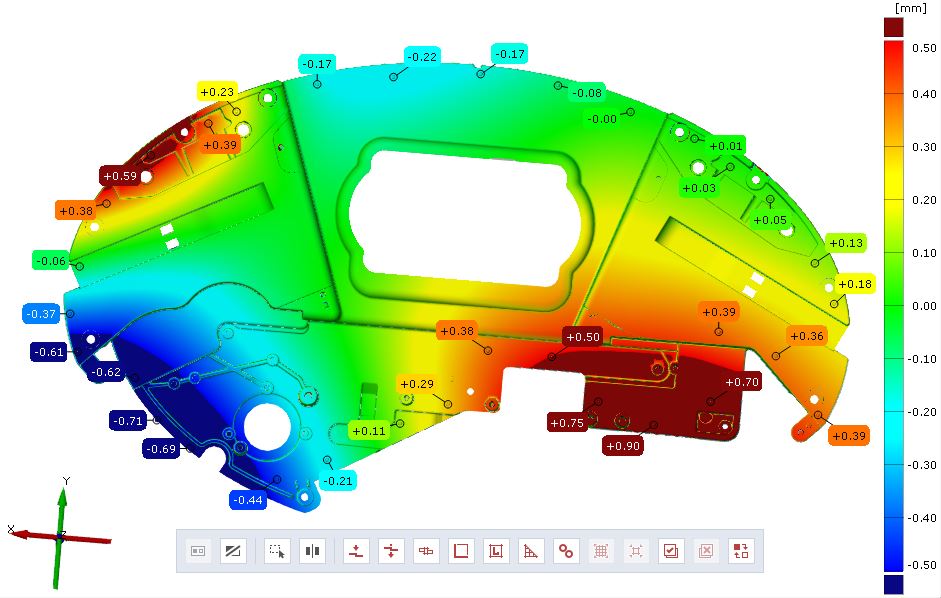

● CAD comparison: Comparision of 3D scan data against a CAD model is faster and more efficient with color maps that make deviations visual.

● Traceability: 3D metrology software reveals how your inspection results are calculated. With passive parametric computation, you will understand details of your inspection, such as which measurement principle is used for your analysis.

● GD&T analysis: The latest 3D metrology software solutions offer tools to complete GD&T analysis quickly.

GOM Inspect Professional offers all the above features, optimizes alignment, performs deformation analysis, inspects airfoils and more.

Automation integration to enable lights-out manufacturing

The pandemic forced companies to adopt a more agile approach to metrology that allows processes to be more hands-off, creating an interest in lights-out manufacturing. Automated inspection systems, such as the ATOS ScanBox BPS, load and unload parts into a measuring cell to run inspection with little to no human interaction.

With new automated metrology solutions, CMMs, 3D scanners, or other measurement tools can inspect a product without human intervention and separate the approved and rejected parts around the clock.

See how our ATOS ScanBox BPS uses an automated optical CMM scanner to inspect parts with little operator interactions.

{youtube}_CnHwSqE5bU{/youtube}

Adaptive machining

Adaptive machining integrates measurement tools with machining tools. You can collect data points even during the machining process by mounting touch probes and laser sensors onto the machine tools.

You can expect the following benefits from adaptive machining:

● You can perform dimensional analysis on the workpiece before the machining process and set optimum work and tool offsets using the measuring tool.

● Software analyzes the data collected by probes and offers real-time feedback to the machine.

● The complete data capture helps the software develop detailed reports on product quality.

● Optimized machining parameters help you reduce scrap.

● An adaptive close loop system ensures a faster and more efficient manufacturing cycle.

Metrology-grade handheld 3D scanners

Metrology-grade handheld 3D scanners enable the collection of accurate measurements without large, immovable traditional CMMs. Using a handheld 3D scanner, you can scan and inspect parts on the spot, allowing you to collect millions of accurate data points in seconds.

These handheld scanners are easy to use, allowing workers to take measurements without extensive training. The data they collect is suitable for quality control inspection, reverse engineering, maintenance and other common applications that typically require a traditional 3D scanner or CMM.

The adoption of MBD/PMI for standardization

The modern metrology industry is seeing the growing use of Model-Based Definition (MBD) with product and manufacturing information (PMI). With MBD, the product's design and manufacturing information is communicated using an annotated 3D model instead of 2D drawings.

By establishing and embedding the design specifications directly into the 3D model, you eliminate errors caused by misinterpretation of 2D drawings and reduce scrap and rework. You can also archive this data as a reference during inspection and throughout downstream processes.

How Accurate is Modern Metrology?

Modern metrology tools are as reliable as traditional metrology tools but with added benefits like speed and ease of use. Modern measuring tools offer you convenience without sacrificing accuracy, and portable solutions allow you to perform metrology-grade dimensional analysis on the spot and at lower costs than traditional CMMs. Below, we'll look at different types of 3D metrology solutions and their accuracy.

Handheld 3D Laser Scanner

Handheld 3D laser scanners with laser technology project a laser dot, line or set of lines onto an object's surface to capture data. The software collects measurements using known data like distance from the object and the distance between the sensor and the laser source to produce a 3D model of the scanned surface.

Handheld 3D laser scanners capture measurement data in real-time. You can collect millions of points in seconds without touching the scanned surface, making it an ideal solution to measure fragile objects accurately.

Blue Light 3D scanner

Like handheld 3D scanners, blue light 3D scanners project light on an object's surface and capture the pattern using multiple cameras. Capable of a large field of view, blue 3D light scanners create 3D models that include intricate details like hemmed edges, rib structures, and hidden defects.

Capable of a large field of view, blue 3D light scanners create 3D models that include intricate details like hemmed edges, rib structures, and hidden defects.

Some blue light 3D scanners are as fast as 0.2 seconds per scan and can capture 100 frames per second with high precision. These metrology-grade 3D scanners provide the high accuracy and precision required to create digital 3D models of airfoils and turbine engine components for quality control in the aerospace industry.

Optical Photogrammetry System

Optical photogrammetry systems like GOM TRITOP help you measure large objects by placing reference points on the target object and walking around it while snapping photos with a camera-like device.

By allowing you to capture the object from multiple directions, this method results in a complete 3D model. Most optical photogrammetry systems provide a portable solution for performing quality control on large objects like cars and aircraft.

What are the Benefits of Modern Metrology?

Modern metrology offers several benefits ranging from easier inspection to industrial evolution.

Quick Inspection

Quick Inspection

Modern metrology tools like accurate 3D scanners and optical CMMs let you quickly scan a part to obtain its 3D model. With modern metrology software like GOM Software, you can generate 3D color maps showing deviations, defects, and analysis that improves your production quality by eliminating errors in the early stages.

Digital Twins

Modern 3D scanning technology collects precise geometric data from the surface of a physical part, resulting in an accurate digital twin. A high-resolution 3D scanner captures even the smallest deformities and patterns and includes them in the virtual model to depict a physical object accurately.

Digital twins enable you to:

● Perform analyses on fragile and expensive parts

● Verify form, fit and function through simulation before physical parts go into production

● Optimize your manufacturing processes

Digitalization

Modern metrology enables digital engineering strategies that improve processes and save costs, materials and time. Having consistent access to accurate data allows the digitalization of physical processes for more in-depth analysis and evaluation. Advanced software-based changes in metrology help manufacturers across all industries progress their digital transformation journey.

What is Modern Metrology?

Modern metrology revolves around data. The latest metrology tools like blue light 3D scanners collect full-field data for evaluation in intelligent 3D metrology software to gain a greater understanding of what's happening with your parts. Leveraging that knowledge helps you make decisions to improve inspection, reverse engineering, quality control, and beyond. Do you want to try out some of these innovations? Contact a CAPTURE 3D team member today.