Professional Checklist for Choosing a 3D Scanner for 3D Printing

3D printing is gaining utility across manufacturing and engineering, especially because it solves many age-old problems, from replicating existing parts to creating prototypes.

If you have a 3D printer-ready digital model of a part, you can 3D print just about anything. But what if you don't have a digital model? In the past, to obtain a digital model, you would need to measure the part by hand to render a model in CAD software or take it to the metrology department. If you needed to replace even a small fractured part with a 3D printed alternative, you would spend hours preparing the 3D model.

Here's the good news: the days of those unnecessary delays are in the past.

You can accelerate 3D model preparation by using a modern 3D scanner to produce a 3D printer-ready mesh comprised of accurate data. Modern 3D scanners allow you to develop a 3D model of the desired part within minutes.

Read on to discover how to incorporate a 3D scanner into your workflow and choose the best 3D scanner for 3D printing.

3D Printing With 3D Scanning: Workflow

You can easily integrate a 3D scanner into your 3D printing workflow. Structured light 3D scanners are an excellent choice for many applications. A structured light 3D scanner works by projecting a grid pattern on the object. Sensors capture the distortion of these projections across the object's surface, generating a point cloud that gets processed into an STL file.

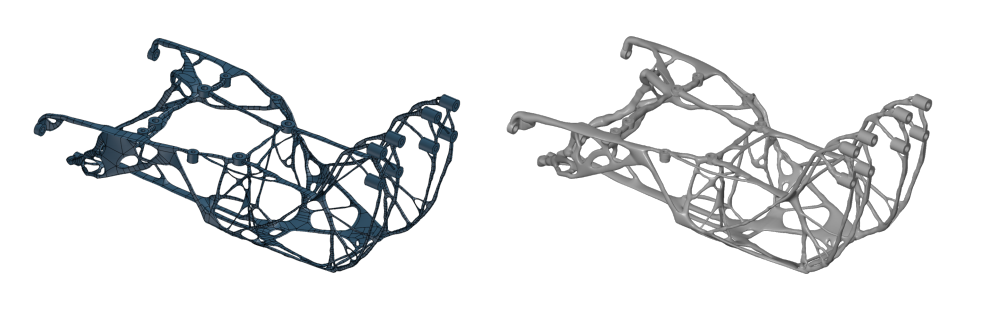

With intelligent 3D metrology software, such as GOM Software, you can analyze, repair, and edit the mesh to finalize the 3D model for 3D printing. Using a robust metrology software solution to create your digital model is another way to increase your 3D printing workflow efficiency.

You can also create a digital workflow with a 3D scanner, 3D printer and a powerful software product like GOM Software:

1. The 3D scanner scans the physical part for dimensions and sends the data to GOM Software.

2. The software transforms the data into a polygon mesh and exports the mesh via an STL file to a 3D printer if print-ready or to CAD software if it requires modifications.

3. The 3D printer uses this STL file to print the desired part.

4. The 3D scanner scans the printed part for inspection.

5. The software compares the inspected data with the reference 3D model, revealing actionable insights to improve part quality or design.

What to Consider When Choosing a 3D Scanner for 3D Printing

When choosing a 3D scanner for 3D printing, it's critical to consider how you intend to use it. Whether you intend to use it for reverse engineering, rapid prototyping, quality control, or something else, you must consider the application parameters. Factors like object size, tolerance, budget, and other requirements are key to choosing the best 3D scanner for 3D printing.

Additional critical factors to consider when choosing a 3D scanner for 3D printing include:

1. Accuracy

Accuracy refers to the fidelity of the 3D model. A high-fidelity 3D model is an accurate digital twin of the physical part it replicates.

In modern manufacturing, digital engineering is a powerful capability that relies on data accuracy, making the metrology department just as critical as ever— especially for 3D printing applications. For example, you may scan an object to 3D print parts for an assembly, but data accuracy is required to meet tight tolerance requirements. In this instance, you should select a 3D scanner for a 3D printer based on the tolerance requirements of the final parts and focus on choosing a 3D scanner with higher accuracy.

3D scanners come in a range of accuracy levels, so consider the following 3D scanner for 3D printing variations when choosing the best selection for your application:

• Laser 3D scanner:

In portable variations, laser 3D scanners allow you to scan your 3D printed part in the metrology lab or factory floor. Metrology-grade handheld laser 3D scanners collect highly accurate data to produce a 3D printer-ready digital model efficiently. For example, CAPTURE 3D's ZEISS T-Scan hawk handheld 3D scanner uses multiple laser sources to quickly achieve high-resolution data from various types of surfaces and conditions.

• Structured light 3D scanner: Metrology-grade structured light 3D scanners, such as ATOS blue light 3D scanners, are known for their high accuracy. These high-resolution 3D scanners collect clean data, creating precise digital twins.

While higher accuracy comes with a higher price tag, cutting corners on quality will also cost you more in the long run. If you work with parts with complex and intricate details, investing in a high-accuracy 3D scanner for 3D printing is best.

2. Resolution

Resolution refers to the smallest distance between any two data points — the higher resolution, the more detail there is on the digitized part. For example, a high-resolution 3D scanner captures slight changes in texture that a 3D scanner with a lower resolution might not define.

However, higher resolution also means a denser point cloud. With more data to process, you'll need a 3D metrology software program with advanced data processing capabilities, such as GOM Software. GOM Software is engineered to process large amounts of high-resolution 3D scan data rapidly, so you can quickly access your 3D model.

If you need a high-resolution 3D scanner for 3D printing, CAPTURE 3D's accurate non-contact 3D scanners are an excellent choice for creating precise, detailed 3D models. For example, ATOS Q 12M generates 3D models with point distances of 0.03 mm to 0.12 mm, collecting up to 12 million points per scan.

3. Ease of Use

When comparing 3D scanners for 3D printing, you should also consider if the 3D scanner is easy to use. You'll need support and training to operate if it requires a lot of training, setup, or steps. The accompanying software should also be user-friendly and compatible with the 3D scanner, so it's easy to process and analyze data quickly.

A good example of an easy-to-use 3D scanner is the GOM Scan 1. With little training to operate and compatibility with GOM Software, this affordable 3D scanner is ideal for 3D printing applications.

GOM Software also offers many features that are advantageous for 3D printing applications. For example, the following features are popular to use when 3D scanning for 3D printing:

• Mesh editing: The mesh editing software function allows you to repair holes in your mesh to achieve a 3D printer-ready watertight mesh.

• Warpage compensation: 3D printed parts often deviate from their actual dimensions due to shrinkage due to different physical and chemical reactions. You can compensate for this undesirable warpage using the warpage compensation software feature in GOM Software.

• Data visualization: With visual data, analysis is more in-depth and comprehensive. Factors like material thickness and flatness can be checked within a few clicks.

• Color enhancement: You can change the color, brightness, contrast, and saturation of the 3D map to highlight different areas.

4. Versatility

Consider the usual objects you scan. Choose a 3D scanner that offers the range, scanning area, and resolution to scan those parts.

For instance, if valves, compressors, and keys are the components you typically scan, you can use a short-range 3D scanner with high resolution to capture intricate details like edges, ribs, and jaws.

If you work with 3D printed parts of many different sizes, the ATOS Q may be a good choice. With interchangeable measuring volumes, the ATOS Q accomplishes 3D scanning of parts of various sizes with just a few quick adjustments.

Choosing a 3D scanner with various possible configurations helps to enhance its versatility.

Consider the following 3D scanner configurations:

• Manual: You can scan the desired object by manually passing the scanner over the object's surface.

• Semi-automated: Many types of 3D scanners can be configured with rotation tables or swivels to help you complete scanning faster. For example, GOM ROT 350 lets you enter a fixed number of rotations and leave the 3D scanner to do the scanning while you attend to other tasks.

• Automated: You can also choose fully automated scanners for higher productivity.

• Automated: You can also choose fully automated scanners for higher productivity.

For maximum versatility, consider the ATOS Q blue light 3D scanner, available in all three configurations.

5. Cost

For many 3D printing applications, a cheap 3D scanner won't deliver the data quality necessary— always remember, you get what you pay for. Choosing an accurate 3D scanner is an investment that delivers ROI for years and helps you save money in the long run.

However, you don't necessarily need to get the most expensive 3D scanner for 3D printing. Instead, define your requirements for accuracy, resolution, throughput, measurement volume, and software, then evaluate which 3D scanner is the best investment based on its ability to meet your requirements and the process benefits it provides.

Ready to Find a 3D Scanner for 3D Printing that Checks the Boxes on Your List?

The first step in finding a 3D scanner for 3D printing is understanding your requirements. Once you know what you need to achieve, use this checklist to help you shop for the best 3D scanner for your application.

The first step in finding a 3D scanner for 3D printing is understanding your requirements. Once you know what you need to achieve, use this checklist to help you shop for the best 3D scanner for your application.

Next, ask for a demo of the 3D scanners that seem like they're a fit. If you don't know where to start, contact us for a demo of the GOM Scan 1. With GOM's blue light fringe projection technology, it is a powerful compact 3D scanner that helps you optimize your 3D printing process. Contact a CAPTURE 3D expert today to help you discover the best 3D scanner for your 3D printing process.