What is 3D Metrology? And Other Things You Should Know if You're New to 3D Scanning

3D metrology is the scientific study of physical measurement using technologies that can create a full 3D representation of an object's geometrical shape. 3D metrology includes various technologies, such as non-contact structured blue light 3D scanners, tactile Coordinate Measurement Machines (CMMs) or computerized tomography (CT) scanners. These 3D metrology tools acquire actual data from physical parts for use in 3D metrology software to perform quality control, accuracy assessment, and various analyses of parts.

In this article, we'll cover:

• What is a Metrology Grade 3D scanner, and where are they used

• The different types of 3D measurement systems

• The applications and professionals who use 3D metrology equipment

What is a Metrology-Grade 3D Scanner?

A metrology-grade 3D scanner is a professional measurement device that meets industry criteria for accuracy, repeatability, reliability, and ease of use. It can capture millions of data points within seconds, creating a high-resolution digital model of the scanned object. Metrology-grade 3D scanners can also integrate with other measurement devices like probes or lasers to provide additional information or functionality.

Advances in 3D metrology technology techniques (hardware/software capabilities) have made 3D scanners more accessible, versatile, and faster than ever before. Some of the latest developments include:

• Automated workflows for data processing and analysis

• Improved algorithms for noise reduction, outlier removal, and data alignment

• Enhanced sensors for capturing surface texture, roughness, and reflectivity

• Increased portability and mobility for scanning large or complex objects

• Expanded compatibility with various CAD formats and software platforms

• Cloud-based services for data storage and sharing

Types of 3D Metrology Systems

Many types of 3D metrology systems are available on the market, each offering advantages and disadvantages depending on the application and requirements. Some of the most common types are:

• Handheld 3D Scanners and Portable or Mobile 3D Scanners: These 3D scanners are easy to transport and use. They are ideal for scanning objects that are difficult to access or move, such as delicate items, large molds, or parts requiring quick checks for maintenance. They can also scan objects of various sizes and shapes, from small parts to large assemblies.

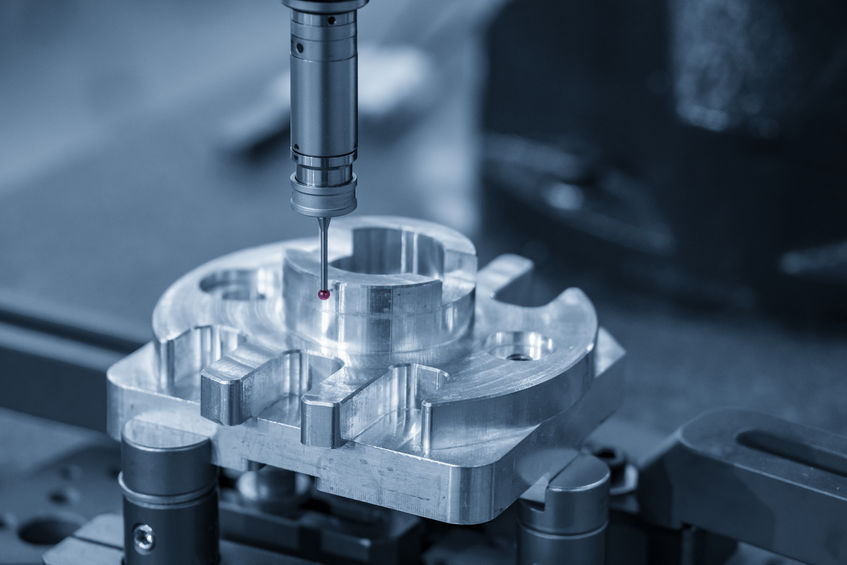

• Tactile CMMs: These coordinate measuring machines (CMMs) use a physical probe to touch specific, preprogrammed points on an object's surface. They are very accurate and precise but also slower than structured light 3D scanners and limited by the number of points they can measure. They are suitable for scanning objects with simple geometry or requiring very tight tolerance.

• Laser & Probe: These hybrid systems combine a laser scanner and a probe in one device. They can scan an object's surface and internal features, such as holes or slots. They can also measure hard-to-reach areas or hidden edges that are not visible to the laser scanner. They are useful for scanning objects with complex geometries or requiring surface and feature inspection.

• Non-contact 3D Scanner: These structured light 3D scanners use light or sound waves to capture the shape of an object without touching it. They can scan delicate, fragile, or deformable objects, such as rubber, plastic, or fabric. ATOS Q is an excellent example of a high-resolution 3D scanner that is lightweight and portable while providing exceptional accuracy down to 0.03 mm point scan distance (the distance between two measured points).

• Multi-sensor CMMs: These are CMMs that can switch between different sensors, such as optical, laser, tactile, or ultrasonic. They can adapt to different scanning scenarios and provide the best results for each situation. They are flexible and versatile for scanning objects with diverse characteristics or requiring multiple measurements. The ZEISS O-Inspect is an example of a multi-sensor CMM that couples quick and precise tactile measurements for surfaces with optical measurements for internal crevices.

What is the Difference Between a CMM and a 3D Scanner?

A CMM and a 3D scanner are both 3D metrology tools that can measure the dimensions and shape of an object. However, they have some key differences in how they work and what they can do.

A CMM uses a physical probe to touch specific points on the object's surface and records their coordinates in a reference system. A CMM can measure only a few preprogrammed points at a time, but it can provide very accurate and precise measurements of those points. A structured light 3D scanner uses light to capture the entire surface of an object and create a digital model known as a digital twin. A 3D scanner can measure millions of points within seconds compared to several seconds for individual points, using a tactile CMM.

A CMM and a 3D scanner can complement each other in some applications, such as reverse engineering or quality control. A CMM can provide reference points or features for aligning or verifying the 3D scanner data, while a 3D scanner can provide surface information or details not captured by the CMM. 3D scanners have the advantage of being faster, portable, and non-contact, delivering accurate 3D visualization of your entire part.

What Industries Use 3D Metrology and Why?

3D metrology is widely used in various industries requiring high-quality, high-performance products or processes. Some of the industries that use 3D metrology are:

• Manufacturing and engineering: 3D metrology supports various manufacturing and engineering activities, such as prototyping, tooling, machining, and assembly. 3D metrology helps reduce costs, increase productivity, and improve the quality of processes and products.

• Medical: In the medical industry, 3D metrology is used to measure and model human anatomy and physiology, such as bones, organs, and tissue. 3D metrology assists in diagnosis, treatment planning, surgery guidance, implant design and fitting.

• Aerospace: 3D metrology is used in the aerospace industry to design, manufacture, and maintain aircraft components and systems, such as engines, wings, fuselage, and landing gear.

• Automotive: In the automotive industry, 3D metrology is used to develop, produce, and test automotive parts and vehicles, such as engines, transmissions, chassis, and bodywork.

• Electronics: 3D metrology is used to inspect and analyze electronic components and devices, such as chips, circuits, boards and displays.

• Power and energy: 3D metrology is used to monitor and control power generation and distribution systems, such as turbines, generators, and transformers in the power generation and energy industries.

• Plastics: 3D metrology is used to measure and analyze plastic materials and products, such as bottles, containers, and films. 3D metrology helps to determine the properties, characteristics, and performance of the materials and products.

• Tooling: 3D metrology is used to measure and verify tooling components and equipment, such as molds, dies, fixtures, and gauges. 3D metrology ensures that the tooling is accurate and consistent and meets the customers' specifications and requirements.

Careers in Metrology

There are many career opportunities for people interested in working with 3D metrology technology. Some of the job titles and industries for careers in 3D metrology are:

• Metrologist: A metrologist is a person who specializes in measurement science and technology. A metrologist can work in various fields, such as calibration laboratories, research institutes, standards organizations, or industrial sectors. A metrologist can develop measurement methods, conduct experiments, analyze data, and report results.

• Quality Engineer: A quality engineer is a person who ensures that products or processes meet quality standards and customer expectations. A quality engineer can work in various industries, such as manufacturing, engineering, or service. A quality engineer can design quality plans, implement quality control systems, perform inspections, and solve quality or production problems.

• Mechanical Engineer: A mechanical engineer is a person who designs, develops, and manufactures new products and solutions for customers. Mechanical engineers use 3D metrology during process development (for measuring prototypes), when reverse engineering legacy or competitor products, and to confirm existing products meet their specifications.

Check out this link for job descriptions and salary details of jobs relating to 3D metrology: Metrology Engineer Careers

Or click here to take a look at the metrology job openings with CAPTURE 3D.

As manufacturing becomes increasingly high-tech, it's essential to understand the differences between the 3D metrology technologies available and which works best for which application, which is why metrology professionals and the technologies and systems they use are in high demand. Check out our other blogs and videos to learn more about 3D metrology and 3D metrology careers. If you're ready to find the right 3D metrology technology for your needs, contact us!