Which 3D Scanners Drive Innovation in the Automotive Industry?

The challenges and demands of the automotive industry are evolving at speeds as fast as the cars it manufactures. Keeping up with customer satisfaction, performance, and competition requires keeping up with technology. Implementing innovative technology like structured blue light 3D scanning is key to developing new processes for modern automotive manufacturers.

Structured blue light 3D scanning is the process of capturing the shape and dimensions of an object using a sensor that projects a heterodyne "fringe" stripe-like pattern onto the physical object's surface. The stripes change in size and direction during data collection. The sensing cameras observe the contrast along the stripes' edges and assign those pixels X-Y-Z coordinates. The data is then processed by software to create a digital 3D model that can be manipulated, analyzed, and used for metrology purposes. 3D scanning has many applications and benefits for the automotive industry, as it can improve the design, prototyping, quality control, inspection, and reverse engineering of automotive components.

In this article, we will explore:

• How 3D scanning is used in the automotive industry

• Examples and benefits of their use

• A case study about 3D scanning for automotive components

Understanding Automotive 3D Scanners

Automotive 3D scanners are 3D scanners that excel in capturing the shape and dimensions of automotive components. They have specific features and configurations that meet the high-speed needs of the automotive industry.

There are different types of automotive 3D scanners available on the market. Some of the common types are:

• Handheld 3D scanners: These are small, lightweight 3D scanners you hold and move around the object, capturing data from different angles. They are ideal for 3D scanning in untraditional environments and hard-to-reach areas.

• Stationary 3D scanners: These blue light 3D scanners are mounted on a tripod or a platform. They require the object to be placed in front of them or on a semi-automatic rotation table to scan from different perspectives.

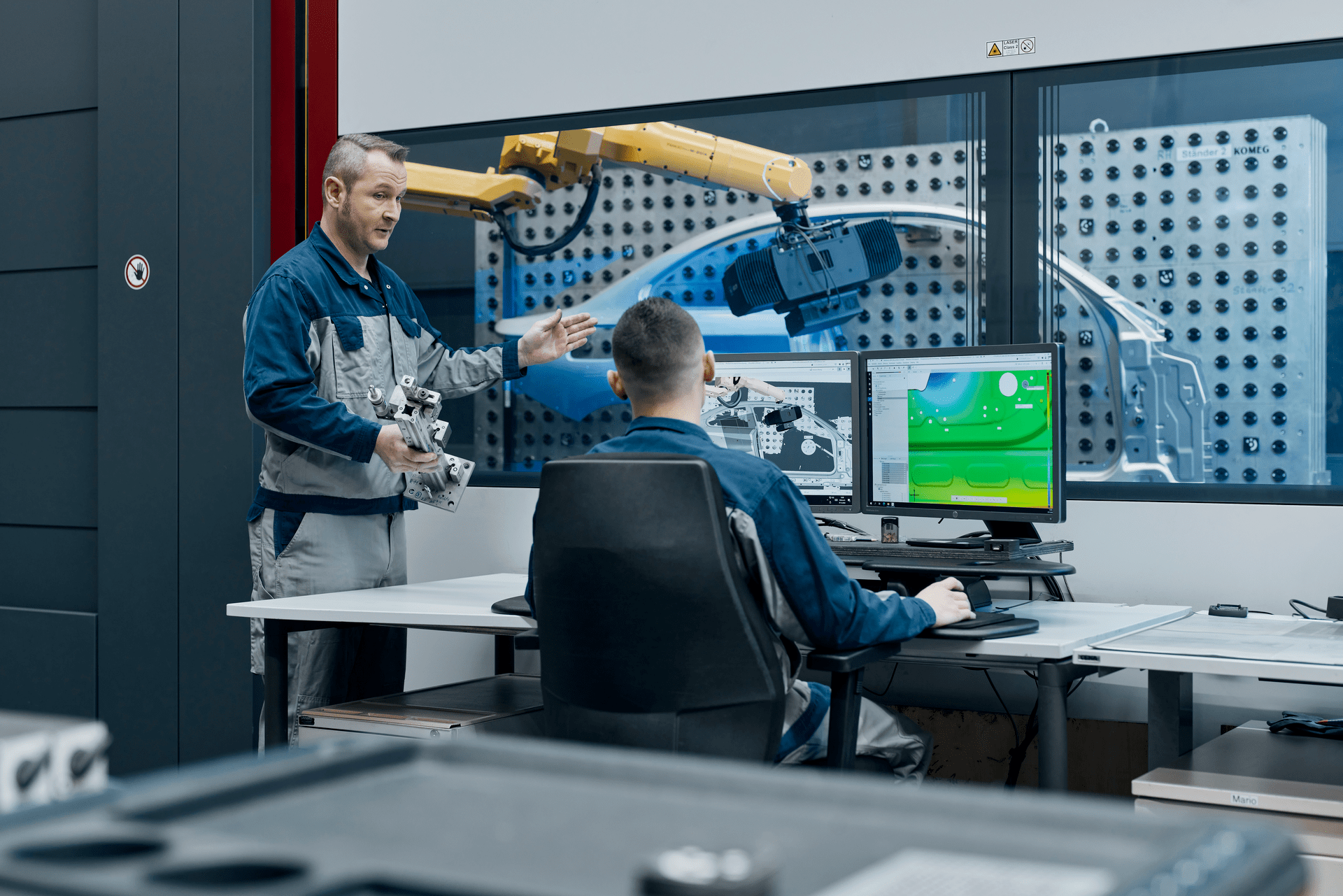

• Automated 3D scanners: These are blue light 3D scanning sensors mounted onto a robotic arm that automatically moves the sensor around the workpiece to capture complete data from optimized angles. They are ideal for increasing throughput with fast and repeatable measurements.

Automotive 3D scanners have various features and capabilities that make them suitable for applications in the automotive industry. Some of the key features and capabilities are:

• Accuracy: This refers to how closely the digital 3D model matches the physical object's shape and dimensions. Accuracy is measured in microns or millimeters and depends on factors such as scanner type, resolution, calibration, and software capability.

• Resolution: This refers to how detailed and fine the digital 3D model is in terms of surface texture and geometry. Blue light 3D scanners capture up to 12 million points per scan.

• Speed: This refers to how fast the scanner can capture the data and create the digital 3D model. Speed is measured in points per second (PPS) and depends on factors such as scanner type, resolution, and software processing. An automotive body panel measuring 1 meter wide can be scanned in a single pass, with a point capture time of as fast as 0.2 seconds.

Applications of Automotive 3D Scanners

3D scanners have various applications in the automotive industry, depending on the stage and purpose of the process. Some of the common applications are:

Automotive Design and Prototyping

Blue light 3D scanners can improve the design and prototyping process by enabling faster and easier creation, modification, and testing of 3D models and prototypes. They can help:

• Capture the shape and dimensions of existing parts or models to create digital 3D models that can be used as references or templates for new designs.

• Modify the digital 3D models by adding, removing, or changing features or parameters to create new or improved designs.

• Print the digital 3D models using 3D printers to create physical prototypes that can be used for further testing, validation, or presentation.

• Enhance precision and accuracy by achieving detailed and exact measurements and representations of parts and models.

Quality Control and Inspection

Blue light 3D scanners can enhance the quality control and inspection process by enabling faster and more comprehensive detection of defects in automotive components and systems. They can help:

• Scan the parts or systems to create digital 3D models that can be compared with the original design specifications or standards using software tools.

• Identify any defects or deviations such as cracks, dents, scratches, warping, or misalignment that may affect the quality or performance of the parts.

• Ensure compliance with industry standards and regulations by achieving consistent and traceable quality control.

Reverse Engineering & Aftermarket Modification

Blue light 3D scanners can facilitate the reverse engineering and aftermarket modification process by enabling easier replication and customization of existing parts. Blue light 3D scanners can be used to:

• Scan parts or assemblies to create digital 3D models, known as digital twins. The resulting digital twin can be used as the basis for new designs for body panels or internal components.

• Create and modify 3D models of custom shapes to create molds and tooling for manufacture.

• Increase flexibility and personalization by creating customized parts or systems to meet customer preferences and needs.

Benefits of Automotive 3D Scanners

Automotive 3D scanners offer multiple benefits for the automotive industry that can improve its processes and products. Some of the main benefits are:

Time and Cost Efficiency

By using accurate blue light 3D scanners, automotive manufacturers can save time and money in various ways. They can:

• Reduce manual measurement time by capturing data in seconds or minutes instead of hours or days.

• Minimize errors and rework costs by achieving accurate and precise measurements that eliminate guesswork and trial-and-error.

• Lower labor costs by reducing human involvement in measurement, inspection, and analysis. Speed and efficiency can be further increased when you implement automated 3D scanning for automotive applications.

Enhanced Accuracy and Precision

By using accurate blue light 3D scanners, automotive manufacturers can achieve enhanced accuracy and precision in various ways. They can:

• Achieve detailed and precise measurements quickly.

• Ensure better product fit and functionality by matching the parts or systems with the design specifications or standards.

• Improve product quality and performance by detecting and correcting any defects or deviations affecting the parts or systems.

Increased Productivity and Innovation

Accurate blue light 3D scanners can enable increased productivity and innovation. They can help:

• Streamline the design and innovation process by speeding up the prototyping and testing to produce new components and assemblies.

• Encourage more flexibility and idea generation by allowing designers to mold shapes in clay or other mediums and then capture the new shapes in digital format.

• Encourage the creation of new designs by modifying existing or competitor designs into new forms.

Choosing the Right Automotive 3D Scanner

When selecting an automotive 3D scanner, there are several factors to consider, such as:

• Accuracy requirements: If you are 3D scanning a part for quality control or inspection, you may need a higher level of accuracy than scanning a part for design or prototyping.

• Portability and ease of use: If you are 3D scanning parts in different locations or hard-to-reach areas, you may need a more portable and user-friendly scanner than if you are 3D scanning parts in a fixed or controlled environment.

• Compatibility with software and workflows: For design, analysis, and reporting purposes, it's important to use a software solution compatible with your 3D scanner. The ZEISS Quality Suite is an all-in-one metrology software solution that seamlessly meets all of these requirements.

When choosing an automotive 3D scanner, it is important to consider specific automotive industry needs, such as:

• Type and size of the parts: Different types and sizes of parts or systems may require a different type of 3D scanner.

• Purpose and goal of your scanning process: Different purposes and goals may require different features and capabilities of your 3D scanner. For example, if you need to save time and increase throughput, an automated 3D scanner would be best.

We offer a range of accurate blue light 3D scanners that can meet your specific automotive industry needs. Some of our 3D scanners for automotive applications are:

• ATOS 5X: This is a laser-based 3D scanner that is great for stamping and bodywork applications. It can capture high-resolution data in seconds with high accuracy and repeatability. It can also scan shiny surfaces without any coating or preparation.

• ScanBox 5 Series: This is an automated 3D scanner that is great for production inspection applications. It can scan large, complex parts or systems quickly and precisely. Its modular layout allows for various configurations and can be scaled to match your required output level.

• TRITOP: This photogrammetry system performs fast and accurate 3D coordinate measurements and deformation analysis. Measuring tasks traditionally performed by tactile 3D coordinate measuring machines can now easily be carried out with the TRITOP system. It requires no complex, heavy, maintenance-intensive hardware and is ideal for large or irregular objects.

Case Study: ADAC Automotive's 3D Scanning Success

ADAC Automotive is a leading supplier of automotive components and systems, such as door handles, mirrors, and lights. They faced several challenges in their design, prototyping, and quality control processes, such as:

• Long lead times and high costs for creating and testing prototypes

• Inaccurate and inconsistent measurements (and inspections) of parts

• Difficulty in replicating and modifying existing parts for new designs

To overcome these challenges, they decided to use the following accurate 3D scanning technology from CAPTURE 3D:

• ATOS Core for scanning their prototypes and parts

• ScanBox 4015 for inspecting their production parts

• Virtual Measuring Room (VRM) software, which intelligently optimizes for automated scanning applications

By using our blue light 3D scanners for automotive applications, they achieved several positive outcomes and impacts on their operations, such as:

• Reduced lead times and costs for creating and testing prototypes

• Increased accuracy and consistency of measurements and inspections

• Enhanced flexibility and creativity in replicating and modifying existing parts for new designs

Contact Us to Get Behind the Wheel and Drive Innovation Today!

Accurate blue light 3D scanners are a technology that can drive innovation in the automotive industry by improving the design, prototyping, quality control, inspection, reverse engineering, and aftermarket modifications of automotive components. However, to get the most out of 3D scanning, you must choose the right 3D scanner for your specific automotive needs.

Contact us if you want to explore the potential of accurate blue light 3D scanning in the automotive industry. We will help you find the best blue light 3D scanner for your automotive needs and show you how it can benefit your processes and products.