We have been using the ATOS system since 2004 and have been extremely impressed with the reliability of the equipment. Often times we have run two shifts, driving the system 20 hours a day with great reliability. Our main applications are Product Definition and Quality Inspection of Industrial Gas Turbine Components. We initially felt that we wouldn't be able to justify the cost of an ATOS system, but after seeing a 30% time savings in our Product Definition applications we acquired a second system after just 9 months.

Vice President of Engineering

ETS Power Group

After an extensive evaluation of competitive systems, we have implemented over a dozen ATOS Scanning systems at 9 of our manufacturing sites. We chose the ATOS systems based on Accuracy, Repeatability, Speed and the Support we received from Capture 3D. A conventional inspection of 500 items including 8 sections and setup would typically take 65 hours. We've been able to reduce that inspection time to under an hour and provide more detail in the process. Typical measurement of 'Trip Strips' has been reduced from 45 hours to 8 hours. Some of our key applications for ATOS have been 1st Article Inspection, In-Process Verifications, Core Inspections and Coating Evaluations.

Engineering Support Manager

Arconic, formerly Alcoa Howmet

Through our evaluations, we determined that the ATOS system provides better accuracies than Laser Scanners and with the organic shapes of Turbine Blades, CMM's do not provide the required detail. Since our initial acquisition in 1998, we have installed six systems at five locations and have been very impressed with the continual software and hardware updates. GOM is obviously making substantial investments to keep ahead of their competition.

Director of Design Engineering

Chromalloy Gas Turbine

We have spent significant time testing artifacts and comparing with traditional methods to prove out the entire process. We have certified the ATOS system for our inspection applications and have encouraged our suppliers to use them to improve their processes. Areas of success for Pratt & Whitney have included Compressors, Tooling, Cases, Turbine Components, IGT Components, Internals & Externals and Nozzles. With the Automation that Capture 3D has integrated, we have increased throughput significantly for production applications.

Advanced Manufacturing Metrology

Pratt & Whitney

Full-field measuring data from CT in conjunction with programmable inspection report creation in GOM Inspect Professional has reduced the tool release process from three or four weeks to three or four days. Inspection now involves far less effort, thanks to the simple color presentation of comparison data. Tool designers detect faults at a glance, without having to work their way through hundreds of measurements to find out.

Both software packages from GOM are ideal for CT data, as they offer mesh processing options, which are lacking in other software packages, as well as professional metrology 3D data evaluation.

In addition to six Professional licenses, free GOM Inspect software is installed on some 60 design engineering computers. It enables subsequent evaluations to be carried out during product development and tool designing stages. It also makes it easier for departments to exchange 3D measurement data and inspection reports. Likewise, these findings can easily be passed on to customers.

Learning videos and tutorials are the easiest and fastest way to get to know GOM Inspect. We pass training material on to both our employees and to customers who use CT services. Our long-term goal is for customers to obtain all measurement data from BJB and, subsequently, to perform the evaluation process themselves with GOM Inspect or GOM Inspect Professional.

X-ray Computed Tomography

BJB GmbH & Co. KG

We use GOM Inspect in two departments in our enterprise – in development inspection and production. In development inspection, GOM Inspect is applied for drawing up initial sample inspection reports after tool production and tool modification. The results are used in our molding department to place subsequent production orders. Besides, with GOM Inspect, we can recognize deviations to molds or existing parts, which do not have a 3D model. In addition, we can produce measurement statistics, file measurement results and produce presentation documents. In our production, GOM Inspect is used to inspect single components for dimensional accuracy (mechanical parameter) through a fast surface comparison at the beginning of the running production.

We have decided to use the GOM Inspect software, as the ATOS Scanner and the related evaluation software ATOS Professional and GOM Inspect Professional facilitate a variety of measuring possibilities and evaluations that are not possible with traditional measurement methods at our plant.

GOM Inspect provides great benefits, including an optimization of workflows (construction of components and assemblies in 3D, construction of injection molds in 3D, measurement of parts based on this data). Likewise, we benefit from improved documentation facilities and an easy disclosure of measurement data. Both aspects provide a better basis for discussion and lead to an enhanced comprehensibility of measurement results. The possibility of subsequently and easily changing metrics and test sequences and continuing with further analyses is an additional advantage. For our company in particular, it is very helpful that changes in documentations following changes in test sequences are possible and easily manageable. This allows for a comparison of Autodesk Moldflow simulations with the finished parts. Additionally, the fast detection of rough deviations through optical illustration (surface comparison) results in huge time savings for us.

In summary, GOM Inspect Software highly supports discussions within different departments in our company (e. g. development inspection and production or injection molding).

Group Manager Development and Approbation Inspection

Kraus & Naimer

The group-wide rollout of the GOM Inspect software is due to start soon at the pilot plants in Oelde and Bünde, before it will be implemented at Miele´s locations in GermanyIn the run-up to the rollout, the software has already been scripted by the IT department. It will be made available to individual PCs via the company's central server. During installation, staff at Miele will be trained in the use of the software.

One reason for deploying the GOM Inspect software throughout the corporate group is the possibility to centralize software management. This ensures that the latest software version is always installed on all PCs, guaranteeing a smooth exchange of data between different locations. All employees can view and edit the evaluations whenever they need to. Another reason is the software's universal applicability.

One typical area of application for GOM Inspect software is technical coordination. These coordination meetings are attended by quality managers, designers, buyers and manufacturers (internal or external). Parts or tools are initially assessed on the basis of false color display resulting from a comparison at CAD data as a image says more than 1,000 figures. Other evaluation which are consulted at these meetings, include cross-sections, material thicknesses and trend analyses.

Quality Management

Miele & Cie. KG

Vald. Birn A/S uses two GOM Inspect Professional licenses for measurement and quality control of production samples from our foundry.

We have invested in GOM equipment and software as we believe that the provide time-savings compared to traditional CMM and give us the great advantage of having much more measurement data to analyze.

One of the advantages of using GOM equipment and software is the fact that the measurement operation can be carried out by more than one person. One person performs the scanning and another makes the measurement report. This means that we do not need metrologists for data collection, but only for analysis and report writing. Each production engineer can also analyze the part he is in charge of, without having to know how to operate the scanner.

Having more people involved means that we can use the equipment optimally, and maintain a more flexible process, which is not dependant on one person only. This is a clear advantage compared to traditional CMM processes, where this is typically the case. At Vald. Birn A/S the system will be used for continuous process control (SPC) and thus it is an important parameter that GOM develops fully automated solutions. Finally, GOM Inspect Pro will be used for measuring and monitoring our casting tools.

Quality Manager

Vald. Birn A/S

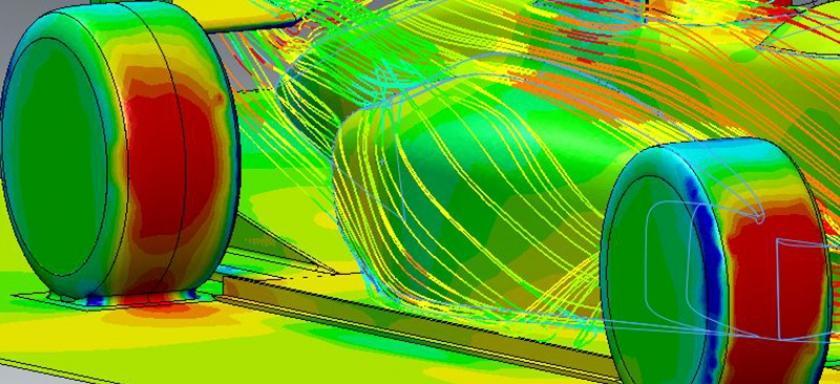

Data from 3D scanners can be utilized for CFD and FEA simulation and analysis. The benefit with ATOS is the accurate scan data and the ability to regularize the mesh which helps CFD/FEA software packages read in the data and measurements.

Having a robust inspection process to improve quality control is critical in today’s world of manufacturing. With accurate 3D scanning and inspection analysis, companies can reduce iterations/tuning loops and quickly derive the proper corrective action without slowing down their time-to-market goals.