The Best Accurate 3D Scanners for Manufacturing in 2023

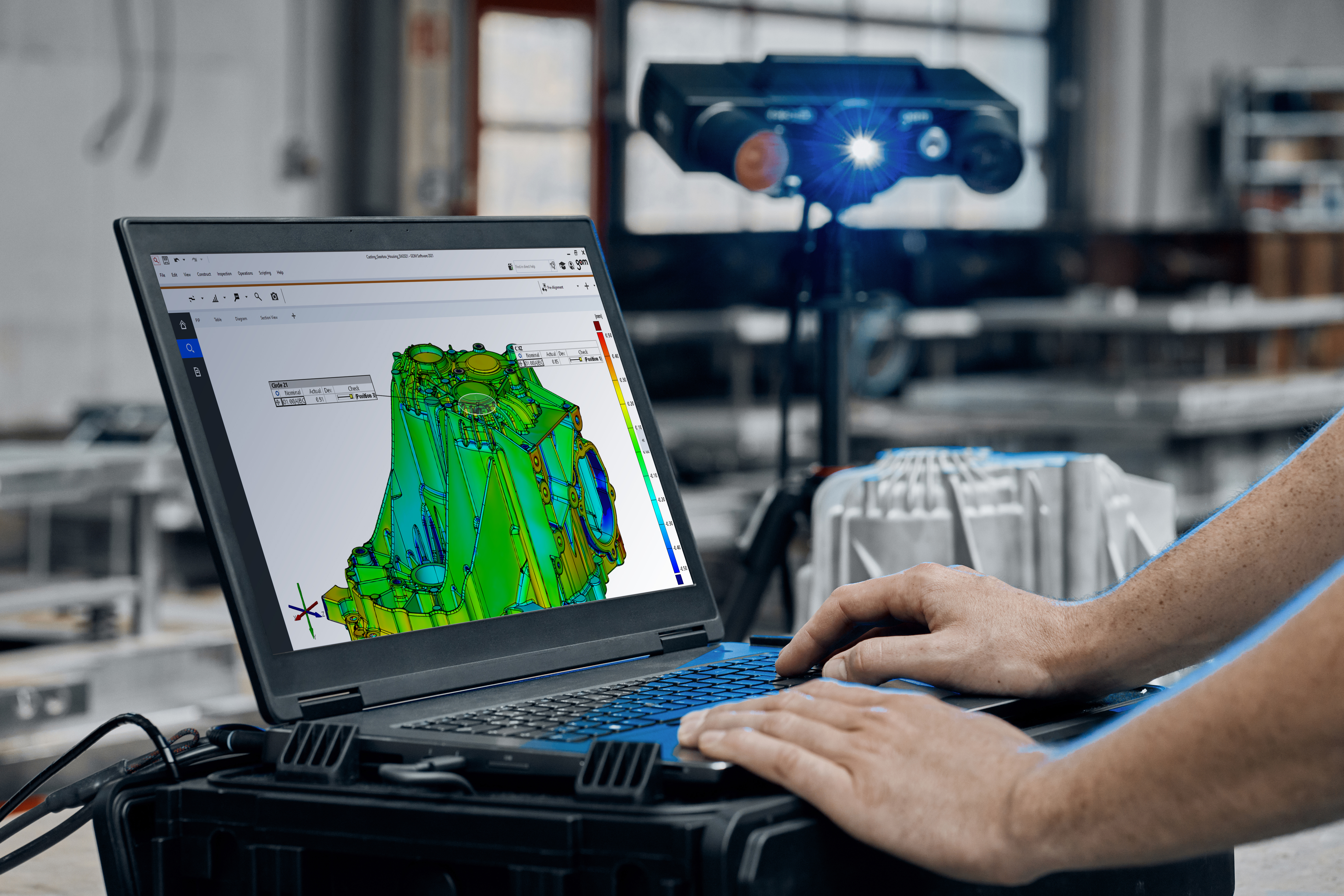

Each new year is an opportunity to improve your processes and products. That often means improving the technology you use within your processes to create your products. That's why we wrote this roundup of the best accurate 3D scanners for manufacturing available in 2023.

Whether you are looking to take the first steps into implementing 3D digitizing solutions or looking for a specific technology for a niche application, read on to learn more about the best accurate 3D scanners for manufacturing available in 2023 and find the right 3D metrology tool for you this year.

What can 3D Scanning be Used for?

3D scanning is useful for measurement and inspection purposes in many applications across various industries, including aerospace, automotive, medical device manufacturing, industrial manufacturing, and many other engineering and technical applications.

3D scanning is useful for measurement and inspection purposes in many applications across various industries, including aerospace, automotive, medical device manufacturing, industrial manufacturing, and many other engineering and technical applications.

Inspection using a 3D scanner allows you to evaluate a complete geometric digital twin of the scanned physical part. This full-field data collection happens because 3D scanners capture millions of geometric data points from the object's surface in seconds— even from intricate or complex shapes. This rapid collection of 3D measurement data is one of the many reasons 3D scanning is extensively used for automotive and aerospace components, which have curved profiles, fine lines and points, and complex geometries.

3D scanning is often used for applications in which traditional inspection and measurement techniques simply can't perform the job as well. Examples include small, molded components, objects with intricate details, and organic or highly irregular shapes.

3D scanning is a powerful tool for quality control in industries requiring fast and reliable data to verify the conformance of products or the efficiency of processes. If resolution, speed, and reliability are important for your business or product, consider investing in 3D scanning.

What Industries use 3D scanning?

3D scanning is extensively used across a range of industries, especially for very small, very large, or very complex geometries. Some of the most common industries which use 3D scanning in manufacturing are:

• Aerospace: Many aerospace components present unique challenges to traditional inspection equipment, given their shape, size, and often complex geometries. The need to reliably verify conformance to strict standards of quality can be met with an accurate 3D scanner for aerospace applications. The measurement and inspection of turbine blades and airfoil profiles can be completed quickly and efficiently with 3D measurement data from a metrology-grade 3D scanner and intelligent 3D metrology software.

• Automotive: Quality control in molded and assembled automotive components is a common use of 3D scanning. Curved body panels, chassis components, and all pressed and injection molded components can be measured and analyzed quickly with an accurate 3D scanner. This inspection speed is a good match for the high-volume production standard of the automotive industry.

• Engineering Services: Many support services within manufacturing find critical uses for 3D scanners. The ability to reverse engineer components and assemblies provides valuable feedback for product designers. Process development and prototyping services benefit from the accurate data metrology-grade 3D scanners collect. The ability to scan an object and print a replica makes 3D scanners the ideal companions for use with 3D printers.

• Medical: The medical and dental industries use 3D scanners to create 3D models of irregular surfaces and organic shapes that are otherwise difficult to measure and analyze. 3D scanning for the medical industry enables the production of prostheses, orthotics and other dental work that enhances the lives of patients and customers worldwide.

How Much Does a 3D Scanner Cost?

3D scanners come at a range of price points depending on your application and industry. Some entry-level scanners cost only a few thousand dollars, while large-scale automated inspection cells require a significant investment to install and commission.

Your specific requirements and levels of quality are factors to consider when assessing your budget. The cost of investment in a reliable, high-quality inspection system could be much less than the cost of producing poor-quality products.

To scope a particular application, contact us!

Which Type of 3D Scanner is the Best?

Determining which type of 3D scanner is best depends on your specific application and requirements. There are, however, some general guidelines to consider for which scanner works best and in which situation.

• Size: The size and geometry of your component are vitally important to determine which scanner is best. Small parts may be scanned using stationary 3D scanners or with the use of a rotation table. Aircraft fairings and car chassis are commonly scanned using automated robotic 3D scanning cells.

• Tolerance: If the tolerance to which you are working is not challenging, then a low-resolution 3D scanner may do the job. However, for manufacturing, engineering services, metrology, or process control, you will need a high-resolution 3D scanner to confirm that the products or processes meet their specifications.

• Part finish: You should also consider the color and texture of your parts when shopping for a 3D scanner. Low-grade 3D scanners struggle to capture accurate readings and details of parts with certain surface textures. However, CAPTURE 3D's industry-leading structured light technology offers various solutions to collect data from any surface color, surface roughness or finish.

• Portability: In-process monitoring of products and near-line metrology can use stationary (fixed-in-place) 3D scanning systems. Consider whether your business needs the added flexibility to scan objects in different locations, premises, or in the field. In this case, a more portable solution, such as a compact 3D scanner or handheld scanning system, may be appropriate. CAPTURE 3D offers a range of 3D scanners in different form factors to meet diverse business needs.

The Best Type of 3D Scanner Technologies

3D scanners generally work using similar basic principles. Light is beamed onto an object's surface, and a camera or sensor captures the reflection. The sensor is a known distance and angle from the light source, so the object's position can be calculated by working out the angle of reflection. As more beams of light are passed over the object's surface, a point cloud is generated, which becomes a 3D model, or geometric digital twin, representing the physical object.

There are two basic types of 3D scanner technologies commonly used:

1. Laser Triangulation: With laser triangulation, individual beams of light are emitted from a laser onto the surface of an object. A sensor captures the reflection of the laser. The laser and sensor are positioned close to each other, facing the object. The three points (the emitter, object, and receiver) form a triangular shape. The precise position of the object is then measured using trigonometry.

2. Structured Light: Structured light is an advanced method of using laser triangulation. The 3D scanner projects a fringe pattern onto the object's surface. Although the telemetry and computations required are much greater for structured light than laser triangulation, the results are also much better. The time to scan a surface is much faster using structured light, and the resolution is much finer.

Best 3D Scanners for Manufacturing in 2023

CAPTURE 3D's collection of accurate 3D scanners is trusted across many industries for various applications. See our list of the best scanners for manufacturing available in 2023 below.

• GOM Scan 1

GOM Scan 1 is a compact 3D scanner that makes a big impact. GOM Scan 1 uses blue light fringe patterns to capture millions of data points to digitalize small to medium-sized objects accurately. The lighting and projection technology filters out ambient light from the environment, making this one of the most robust 3D scanners for small parts available on the market.

The GOM Scan 1 is most commonly used for 3D printing, reserve engineering, design, and medical and healthcare applications. This compact 3D scanner is easy to set up and compatible with automatic turn tables for a semi-automated 3D scanning experience. • ATOS 5

• ATOS 5

ATOS 5 is CAPTURE 3D's flagship product. ATOS stands for Advanced Topological Optical Sensor, and the system delivers on its advanced claim. Engineered with industry-leading features, ATOS 5 is the right choice for professional 3D scanning results.

The highly powerful light source allows the collection of precision data, even in harsh industrial lighting conditions. This blue light 3D scanner rapidly collects accurate data, with speeds as fast as 0.2 seconds per scan and 100 frames per second.

Ideal for industrial automation, the speed and accuracy of the system lends itself to the inspection of manufactured components and automotive and aerospace assemblies.

• ATOS 5X

ATOS 5X is optimized for larger components and assemblies and is ideal for automotive panels and aerospace fairings. Using an integrated laser light compressor, ATOS 5X generates an extra-bright blue light to collect accurate, high-resolution 3D scan data. This capability enables data collection from large surface areas in record time, such as the complete digitalization of large automotive panels in 0.2 seconds.

ATOS 5X is engineered for tooling companies, press and molding producers, automotive body shops, and car manufacturers. Automating your ATOS 5X lets you 3D scan an entire car body, inside and out, in only about 30 minutes.

• ATOS 5 Airfoil

The ATOS 5 Airfoil takes CAPTURE 3D's industry-leading ATOS 5 platform and optimizes the system for the aerospace and power generation sectors.

Aerospace and turbine components are particularly challenging to digitize and inspect because of their complex geometry, demanding specifications, and sensitivity to geometry defects. ATOS 5 Airfoil features a sensor design that brings the lenses closer to deliver a deeper field of view. This modification allows for the capture of more intricate details and higher resolution data to be collected. Ideally suited for turbine blades, nozzle guide veins, and compressor components, this accurate 3D scanner can be used manually or integrated into an automated cell.

Aerospace and defense companies trust the ATOS 5 Airfoil for their manufacturing and inspection requirements.

• ATOS Compact Scan Lightweight, compact and portable, the ATOS Compact Scan is ideal for use on the go. Weighing only 4 kg, the system is ideal for the lab, shop floor, in the field, or in production environments.

Lightweight, compact and portable, the ATOS Compact Scan is ideal for use on the go. Weighing only 4 kg, the system is ideal for the lab, shop floor, in the field, or in production environments.

The ATOS Compact Scan's advanced lighting technology can quickly capture between 8 and 12 million data points in just one second. The system offers high-end performance with the convenience of packing everything you need into a single carry case: the scanner, laptop, software and all the accessories.

Designed for manual use, the ATOS Compact Scan can be easily paired with a touch probe (for example, while measuring deep blind holes), with the ability to change between con tact and non-contact data collection instantly.

tact and non-contact data collection instantly.

• ZEISS T-SCAN hawk 2

The ZEISS T-SCAN hawk 2 is a handheld 3D scanner offering a vast range of flexibility. With pre-installed GOM Inspect Software, this accurate 3D scanner requires no additional hardware before getting to business and capturing high-resolution data.

The ZEISS T-SCAN hawk 2 is the first portable handheld laser scanner with the new satellite mode to scan large areas without coded markers. Satellite mode allows you to collect accurate 3D measurement data from areas multiple meters in size. You can use this handheld 3D scanner in unique situations, such as maintenance, repairs, large-scale objects, construction and legacy component applications.

The ZEISS T-SCAN hawk 2 is the best handheld 3D scanner for accuracy, speed and portability for many industries and applications.

• ATOS Q

Q is for quality on this metrology grade digitizing 3D scanning system. Similar in design and specification to the flagship ATOS 5, it offers a lower price-to-performance standard for quality control equipment in the manufacturing industry.

Capable of capturing 8 to 12 million points per scan, this accurate 3D scanner comes with interchangeable lenses. The ability to quickly change lenses provides flexibility to meet your needs as they change.

Specially designed for metrology and industrial applications, the ATOS Q can be integrated into semi-automated or fully-automated solutions, including the GOM ScanCobot or the ATOS ScanBox 4105.

Wondering Which 3D Scanner is Best for Me? Contact Us!

The demanding nature of modern manufacturing means 3D scanning provides a huge advantage over other inspection techniques. The ability to tap speed, accuracy, precision, and flexibility using a non-contact solution makes a compelling case for exploring 3D scanners in 2023.

The best way to learn which 3D scanners to use for your manufacturing application is to experience a demo with a CAPTURE 3D team member. You can also download our ROI calculator to help you learn how quickly you can receive a return on your technology investment!